Plasma gasification and melting system for solid waste centralized processing

A plasma, gasification and melting technology, applied in the direction of solid waste removal, waste treatment, chemical instruments and methods, etc., can solve the problems of high investment and treatment costs of plasma technology, and achieve the suppression of volatilization and the formation of nitrogen oxides, The effect of reducing the amount of dust and reducing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

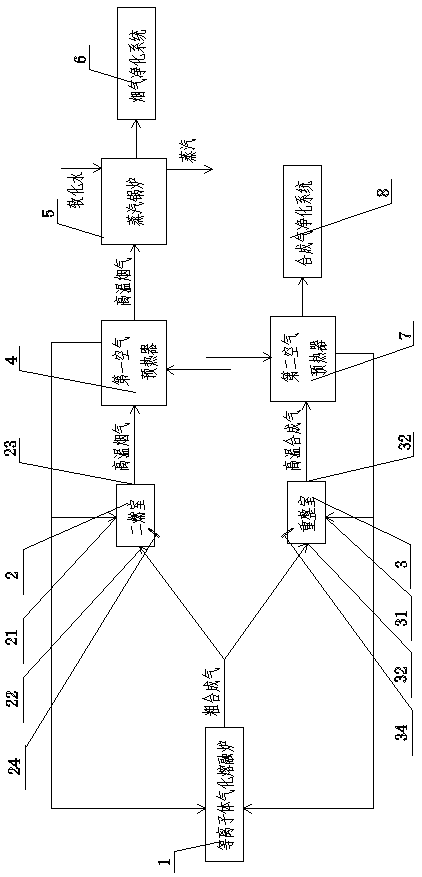

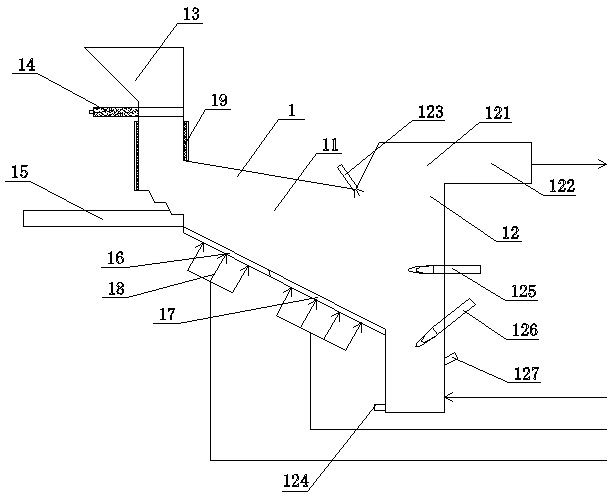

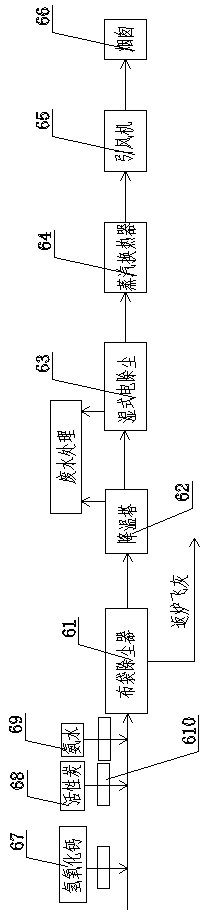

[0033] As shown in Figures 1-4, the present invention includes a plasma gasification melting furnace 1, and the plasma gasification melting furnace 1 includes a gasification incinerator 11 and a plasma melting furnace 12, and one end of the gasification incinerator 11 is provided with a feed hopper 13 The lower part of the feed hopper 13 is cylindrical and is provided with a cooling water jacket 19, the outlet of the feed hopper 13 is provided with an electric gate 14, and the gasification incinerator 11 at the outlet end of the feed hopper 13 is equipped with a pusher The feeder 15, the bottom of the gasification incinerator 11 is an inclined downward slope, and the drying section fire grate 16 and the gasification section fire grate 17 are arranged in sequence, and the bottoms of the drying section fire grate 16 and the gasification section fire grate 17 are respectively provided with The primary air inlet 18, the other end of the gasification incinerator 11 is an opening, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com