Controllable sand flow infinitely variable speed fan blade abrasion testing device

A technology of infinitely variable speed and fan blades, which is applied in the direction of testing wear resistance, etc., to achieve the effects of reducing air pollution, stabilizing the flow field, and reducing the amount of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

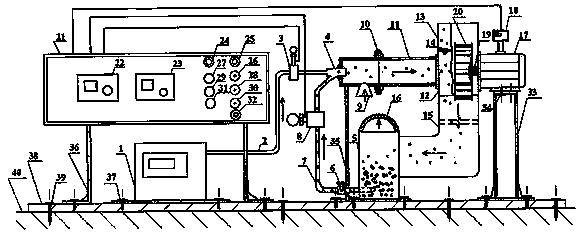

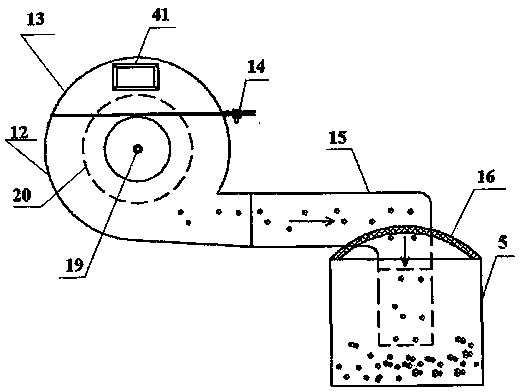

[0040] see figure 1 , figure 2 and image 3 As shown, this embodiment is a test of the erosion performance of centrifugal fan blades.

[0041] This embodiment is composed of air compressor 1, gas delivery pipe 2, pressure sensor 3, spray gun 4, sand storage chamber 5, sand flow control valve 6, sand pipe 7, particle flow sensor 8, air intake pipe 11, erosion and wear Test room 12, erosion wear test room upper cover 13, air outlet pipe 15, dust collector 16, motor 17, frequency converter 18, fan impeller 20, control cabinet 21, motor support 33, intake pipe support 35, control cabinet support 36 , angle iron frame 38 components;

[0042] Among them, the air compressor 1, the gas delivery pipe 2, the air pressure sensor 3, the spray gun 4, the air intake pipe 11, and the erosion wear test chamber 12 are connected in sequence, and the air inlet 9 is arranged under the air intake pipe 11, and the erosion wear test chamber The cover 13 is movably installed on the upper part of...

Embodiment 2

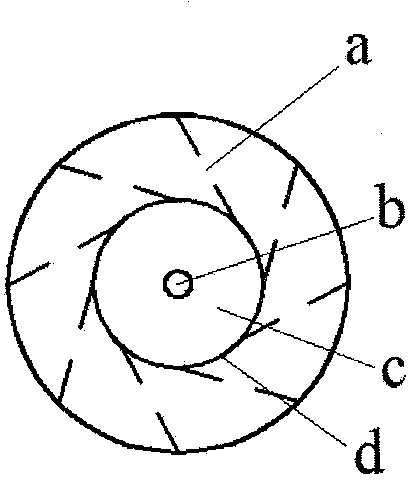

[0050] see figure 1 , figure 2 and Figure 4 As shown, this embodiment is an erosion performance test of an axial flow fan blade.

[0051] This embodiment is composed of air compressor 1, gas delivery pipe 2, pressure sensor 3, spray gun 4, sand storage chamber 5, sand flow control valve 6, sand pipe 7, particle flow sensor 8, air intake pipe 11, erosion and wear Test room 12, erosion wear test room upper cover 13, air outlet pipe 15, dust collector 16, motor 17, frequency converter 18, fan impeller 20, control cabinet 21, motor support 33, intake pipe support 35, control cabinet support 36 , angle iron frame 38 components;

[0052] Among them, the air compressor 1, the gas delivery pipe 2, the air pressure sensor 3, the spray gun 4, the air intake pipe 11, and the erosion wear test chamber 12 are connected in sequence, and the air inlet 9 is arranged under the air intake pipe 11, and the erosion wear test chamber The cover 13 is movably installed on the upper part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com