Device for drying hydrous waste plastic

A drying device and technology for waste plastics, applied in drying gas arrangement, drying solid materials, non-progressive dryers, etc., can solve problems such as unfavorable cracking treatment, unsuitable treatment of plastic waste, etc., to improve drying efficiency and reduce dust volume , the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is explained below in conjunction with accompanying drawing:

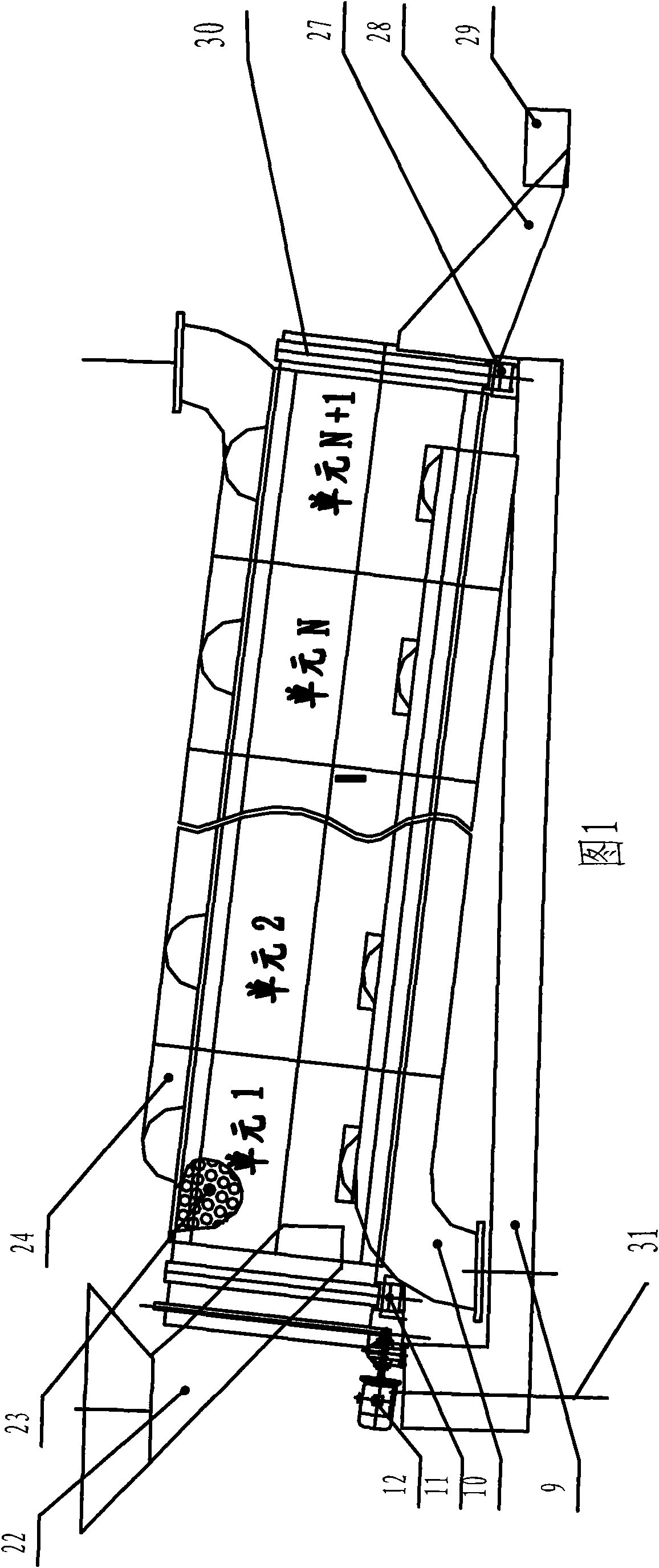

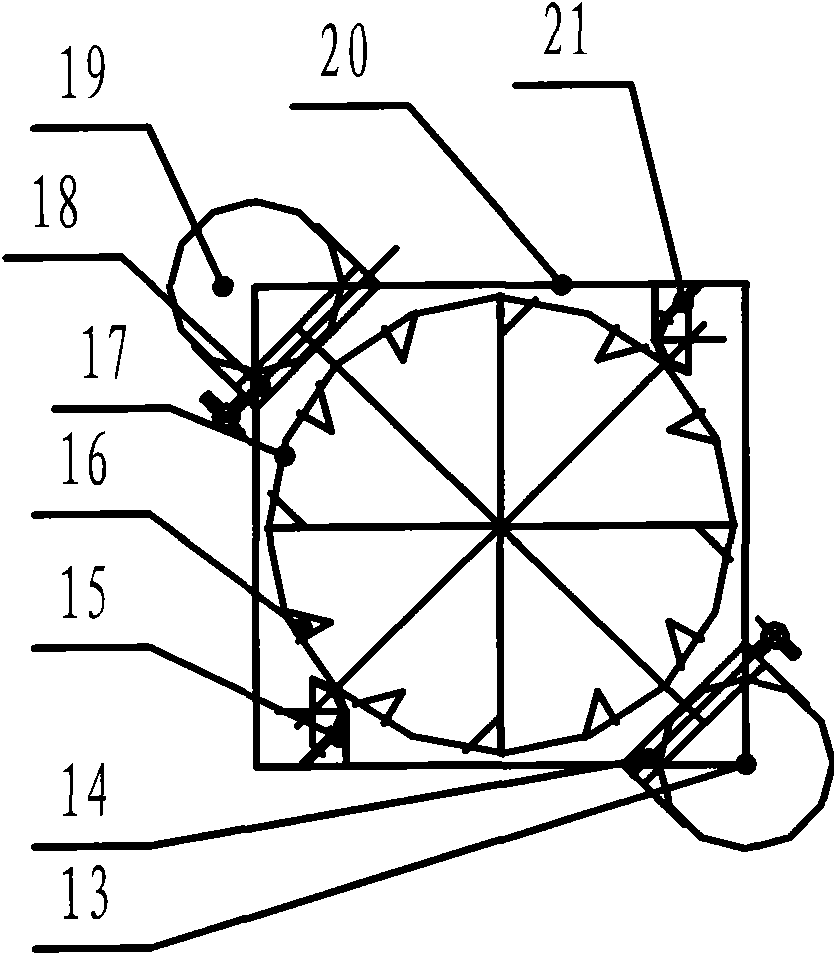

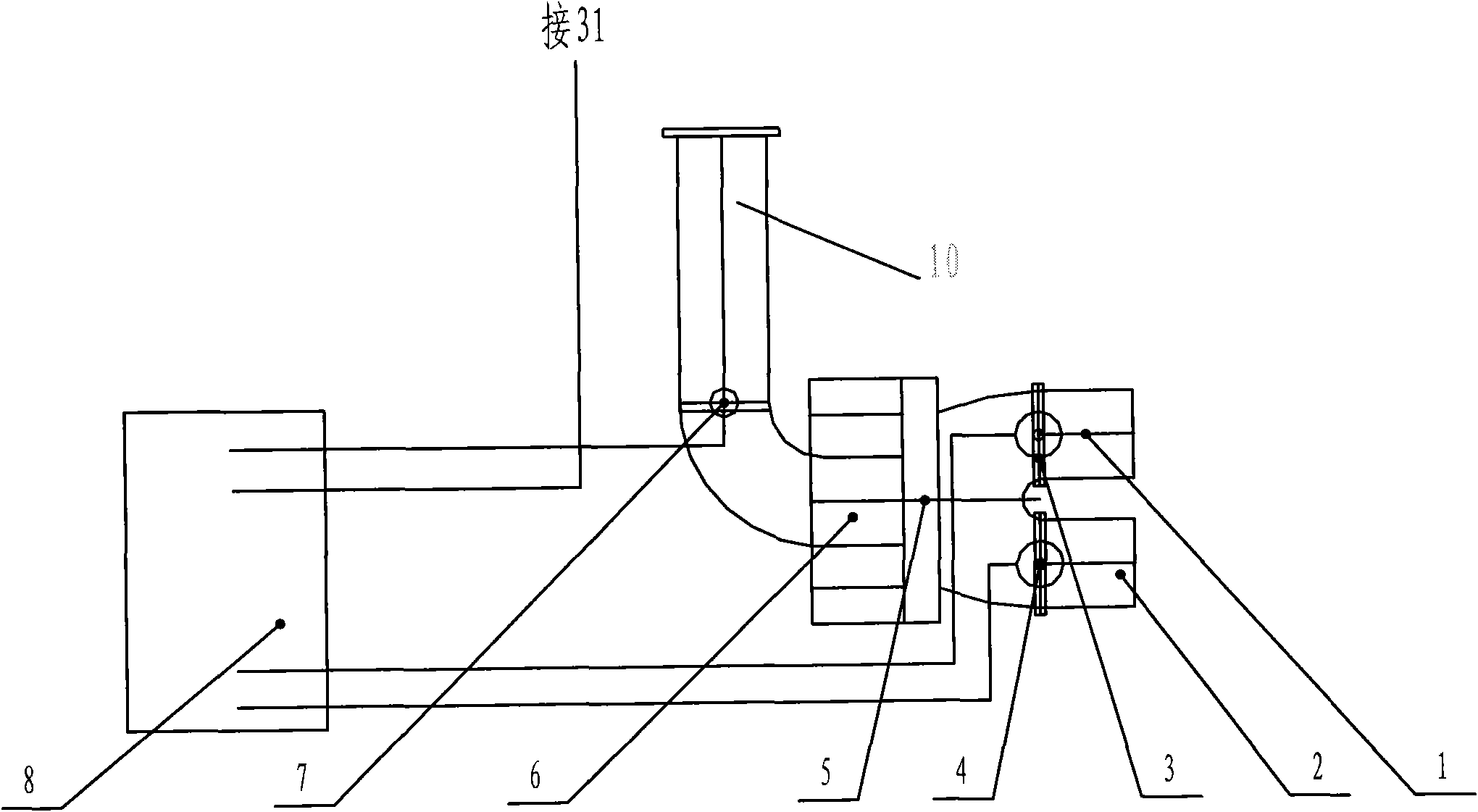

[0015] see figure 1 and figure 2 , the device of the present invention consists of a sealed outer wall 20, a drying chamber 17 that is located in the outer wall 20 and can rotate relative to the outer wall 20, a motor that drives the drying chamber 17 to rotate, a reducer 12, and an air inlet pipe 10 and an exhaust pipe 24. , wherein: the drying chamber 17 is a cylindrical member with a circular section. The front end of the drying chamber, that is, the end where the motor reducer is arranged in the figure, is provided with a feed inlet and a feed guide plate 22, and the tail end of the drying chamber is provided with a discharge outlet and a discharge guide plate 28. Ventilation holes 23 are opened on the wall of the drying chamber, and ribs 16 protruding inward are arranged inside the wall. There is a space between the sealed outer wall 20 and the drying chamber 17, and the drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com