Method for regenerating inactivated Ag/Al2O3 catalyst in situ by utilizing dielectric barrier discharge plasmas

A dielectric barrier discharge and plasma technology, which is applied in catalyst regeneration/reactivation, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve catalyst deactivation and affect catalyst nitrogen oxides Removal of problems such as the ability to achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

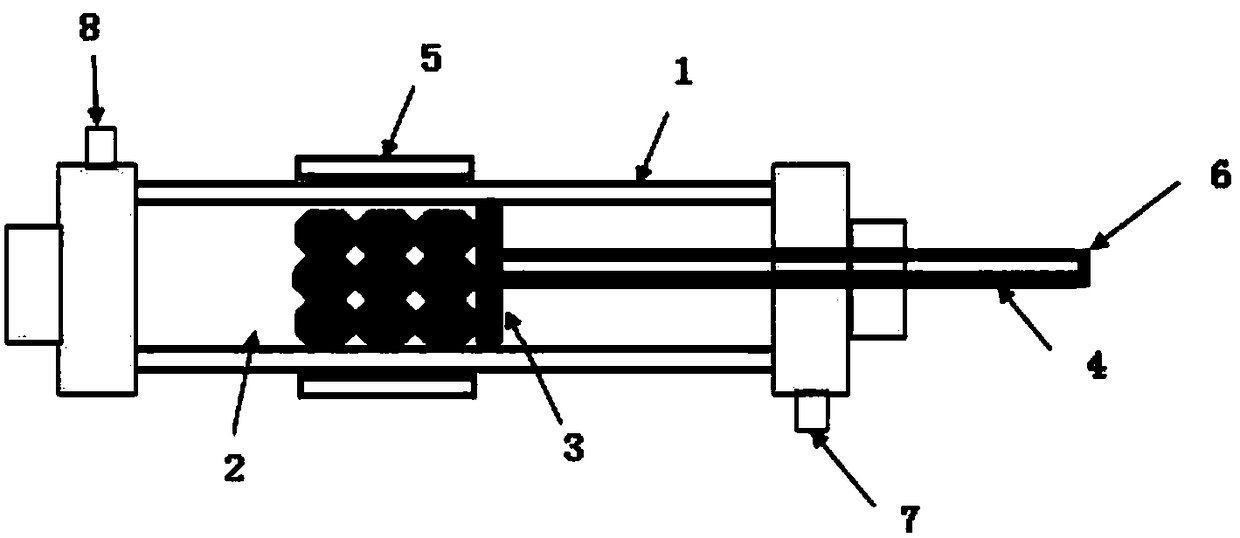

[0024] Put a long straight high-voltage electrode with a diameter of 1.5mm into a quartz electrode protection tube with an inner diameter of 2.5mm and fix it at the center of the quartz tube reactor with a fixing ring. Use a quartz reactor with a wall thickness of 4mm and an inner diameter of 8mm as the medium. Tungsten wire tightly wound stainless steel mesh is used as the grounding electrode around the tube reactor. Both the high voltage electrode and the ground electrode adopt a coaxial wire barrel structure.

[0025] Preparation of Catalyst Ag / Al2 o 3 : According to Ag and Al 2 o 3 Mass ratio, respectively weighed (2, 3, 5wt%) / Ag / Al 2 o 3 A total of 5g of silver nitrate and 20-160um small alumina particles are required. Take 5ml of deionized water to completely dissolve the silver nitrate to obtain a silver nitrate aqueous solution. Immerse the 20-160um alumina small particles in the silver nitrate aqueous solution and let it stand at room temperature 12h, then put it...

Embodiment 2

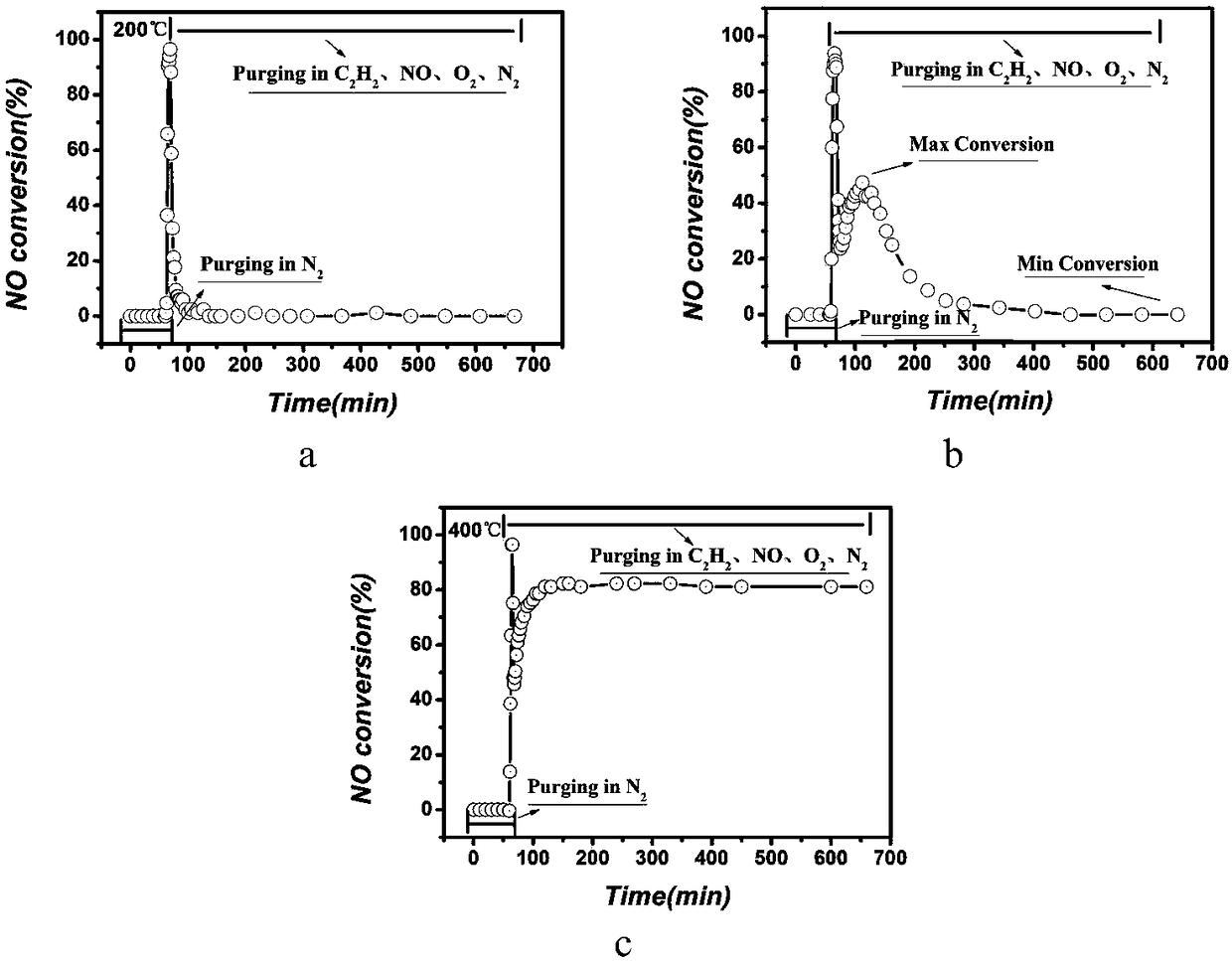

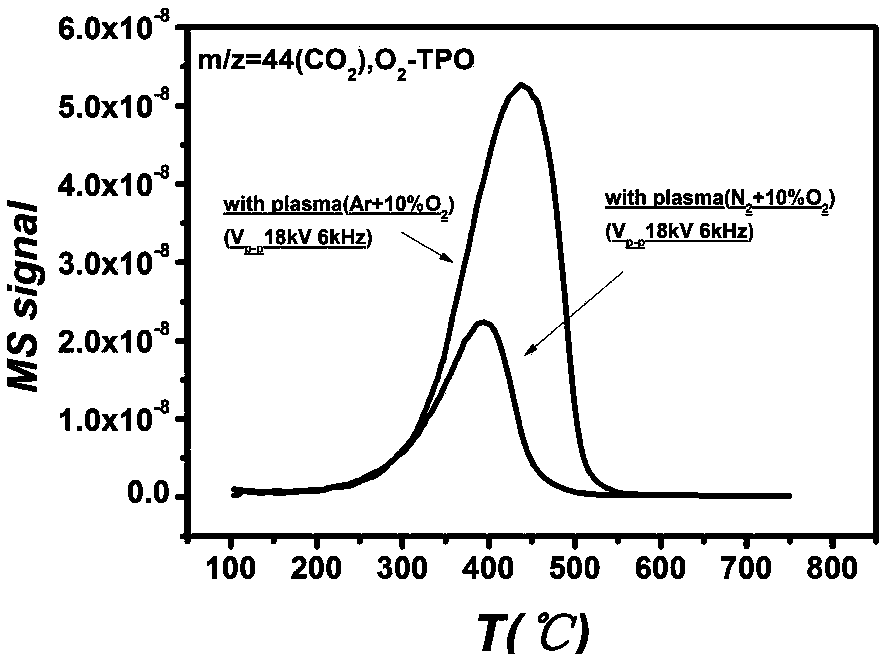

[0028] Adopt the device of embodiment 1, fresh 2%Ag / Al 2 o 3 Catalyst first in N 2 Heated to 550°C for activation treatment under the atmosphere, and then in N 2 Experiments were carried out at temperatures up to 300°C. 1500ppm C 2 h 2 , 500ppm NO, 10vt%O 2 , N 2 As a balance gas, the air speed is 15000h -1 The raw material gas is connected to the reactor for reaction, and the deactivation test reaction is carried out for 600min until the catalyst is deactivated. A deactivated catalyst is placed within the plasma generation region. The plasma discharge temperature is discharge at room temperature, the discharge voltage is 18kV peak-to-peak frequency, and the frequency is 6kHz. At the same time, the treatment atmosphere is examined separately. N 2 treated with Ar, at O 2 Two kinds of background gases were used to treat the deactivated catalyst for 2 hours under the condition of existence. O 2 -TPO,O 2 -TPO experimental condition is to take deactivated catalyst 100m...

Embodiment 3

[0030] Adopt the device of embodiment 1, fresh 2%Ag / Al 2 o 3 Catalyst first in N 2 Heated to 550°C for activation treatment under the atmosphere, and then in N 2 Experiments were carried out at temperatures up to 300°C. 1500ppm C 2 h 2 , 500ppm NO, 10vt%O 2 , N 2 As a balance gas, the air speed is 15000h -1 The raw material gas is connected to the reactor for reaction, and the deactivation test reaction is carried out for 600min until the catalyst is deactivated. A deactivated catalyst is placed within the plasma generation region. The plasma discharge temperature is discharge at room temperature, the discharge voltage is peak-to-peak 18kV, the frequency is 6kHz, and the treatment atmosphere is N 2 gas, inspected at different contents of O 2 Effect of plasma treatment on surface carbon of deactivated catalysts in the presence of conditions. O 2 -TPO,O 2 -TPO experimental condition is to take deactivated catalyst 100mg, 10%O 2 +N 2 From 100°C to 750°C in 130 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com