Battery management system and control method thereof

A battery management system and battery technology, applied in battery/fuel cell control devices, secondary batteries, secondary battery repair/maintenance, etc., can solve the problem of low energy utilization efficiency of batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

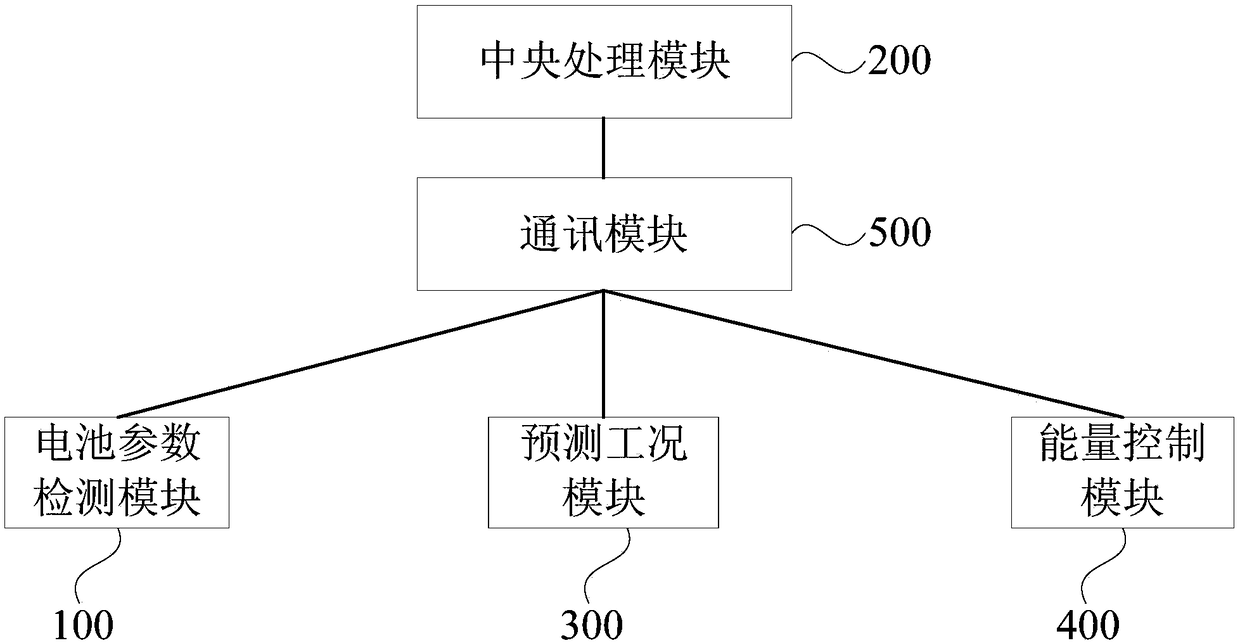

[0053] figure 1 It is a schematic structural diagram of a battery management system provided by Embodiment 1 of the present invention. This embodiment is applicable to the situation where the battery energy is controlled in combination with the actual short-term working conditions of the vehicle. The battery management system is used to manage the energy of the vehicle battery , the battery management system is electrically connected to the battery of the vehicle and the vehicle controller of the vehicle respectively, and is used to collect and process the parameters of the battery, specifically including:

[0054] The battery parameter detection module 100 is electrically connected to the battery, and is used to collect battery parameters in real time and output the battery parameters;

[0055] The central processing module 200 is used to obtain battery parameters and calculate the battery remaining capacity of the battery according to the battery parameters after the battery...

Embodiment 2

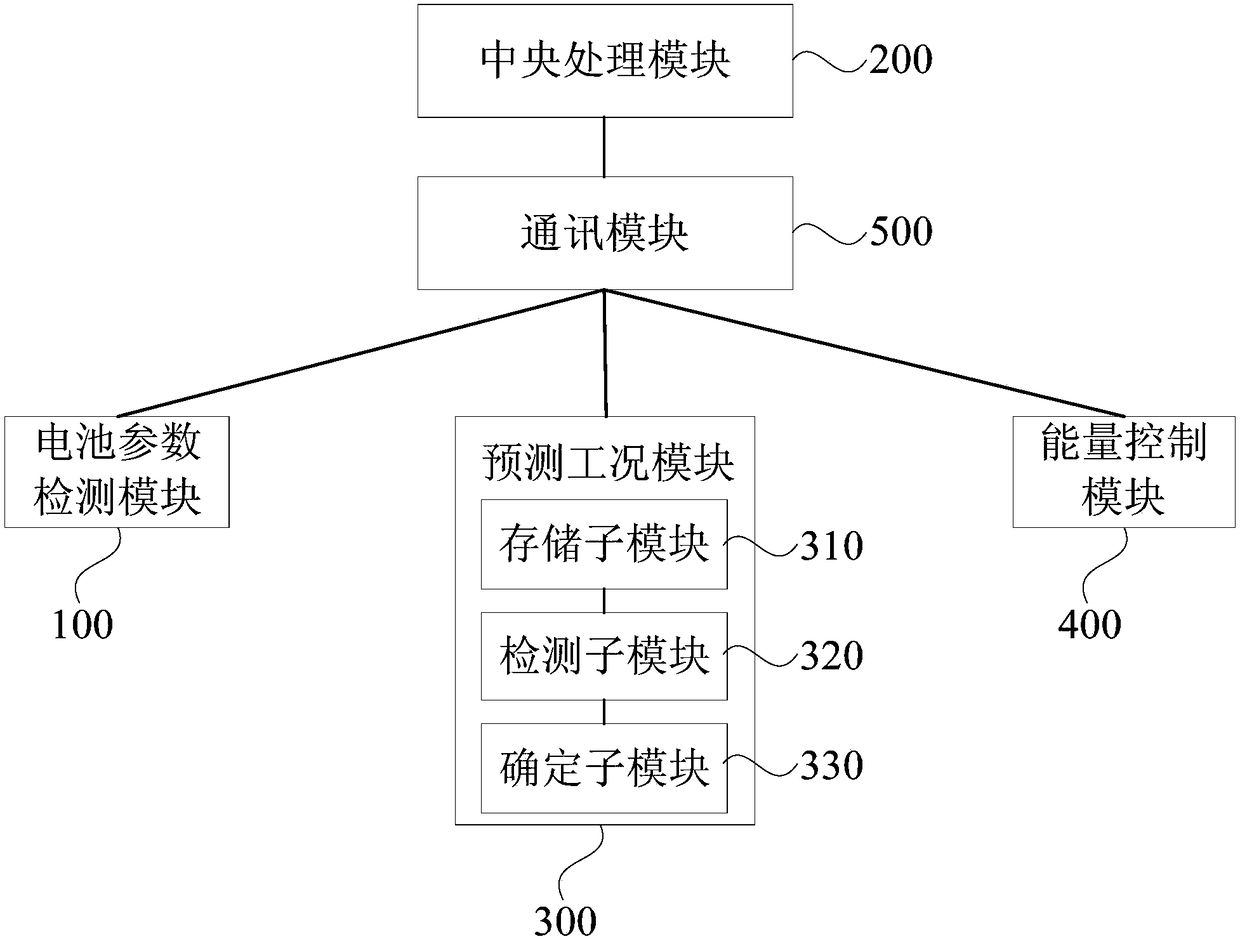

[0070] figure 2 It is a schematic structural diagram of a battery management system provided by Embodiment 2 of the present invention. This embodiment is applicable to the situation where the battery energy is controlled in combination with the actual short-term working conditions of the vehicle. This embodiment is based on the above-mentioned embodiments. A battery management system is further provided.

[0071] Optionally, the vehicle operating condition data includes various vehicle states and the duration corresponding to each vehicle state, and the various vehicle states at least include starting, accelerating, decelerating and braking;

[0072]The battery working condition data includes battery remaining capacity, battery temperature, charging and discharging state, battery current, and battery voltage, and also includes the first current to the mth current and the first current duration of the battery at the first battery remaining capacity and the first temperature. ...

Embodiment 3

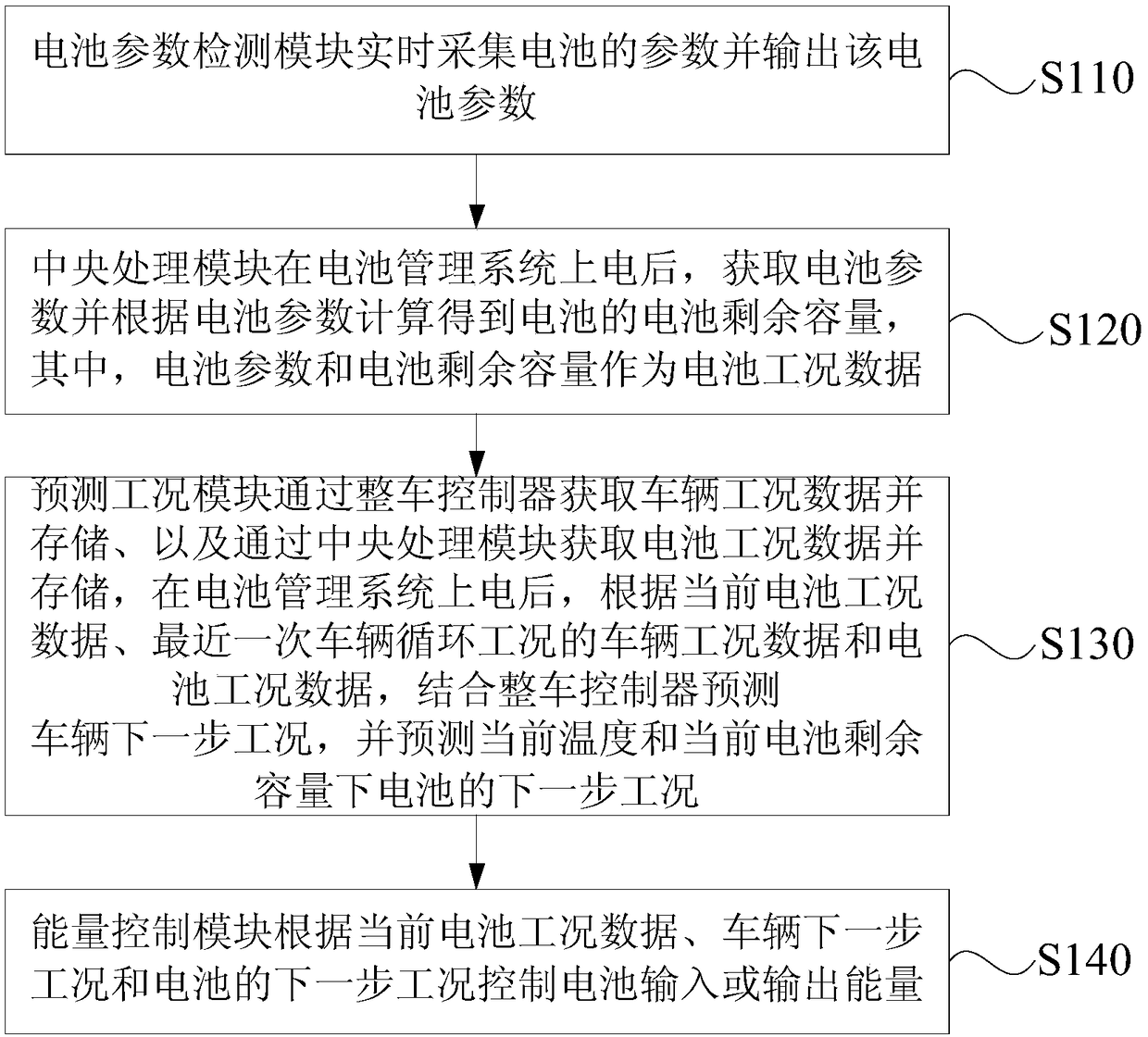

[0096] image 3 It is a flowchart of a control method of a battery management system provided by Embodiment 3 of the present invention. This embodiment is applicable to the situation where the battery energy is controlled in combination with the actual short-term working conditions of the vehicle. The battery management system is connected with the battery of the vehicle and The vehicle controller of the vehicle is electrically connected to collect and process battery parameters. The battery management system includes: battery parameter detection module, central processing module, prediction working condition module, and energy control module; battery parameter detection module and battery Electrically connected, the predicted working condition module is electrically connected to the central processing module and the vehicle controller, and the energy control module is electrically connected to the central processing module; the control method can be executed by the battery man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com