Photo-etching alignment precision measurement accuracy evaluation method

A technology of overlay accuracy and lithographic overlay, which is applied in the fields of optics, pattern surface photolithography, semiconductor/solid-state device testing/measurement, etc. It can solve problems such as difficulty in obtaining evaluation and verification, and reduce evaluation costs. Satisfies the evaluation needs and has strong designability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

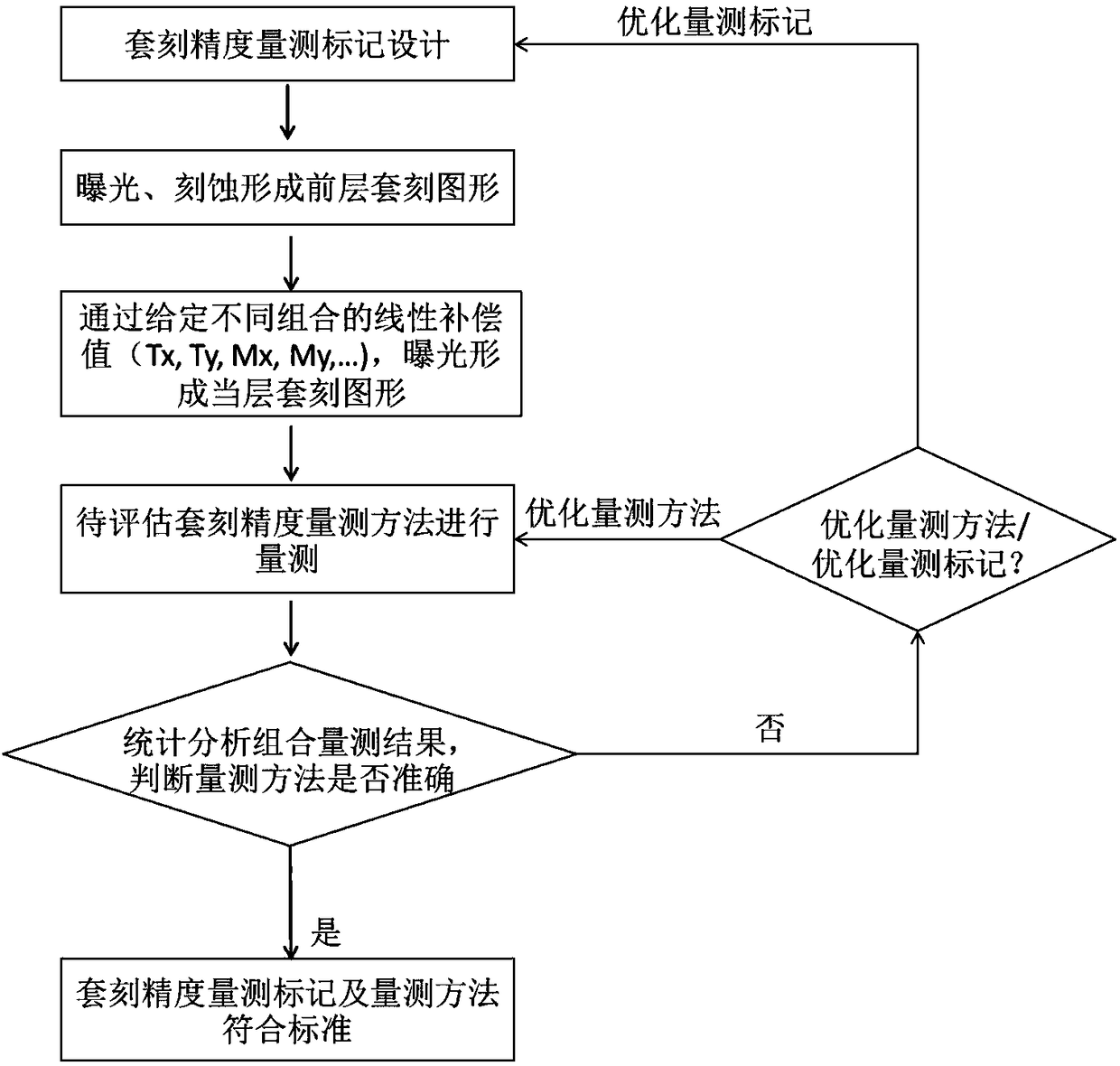

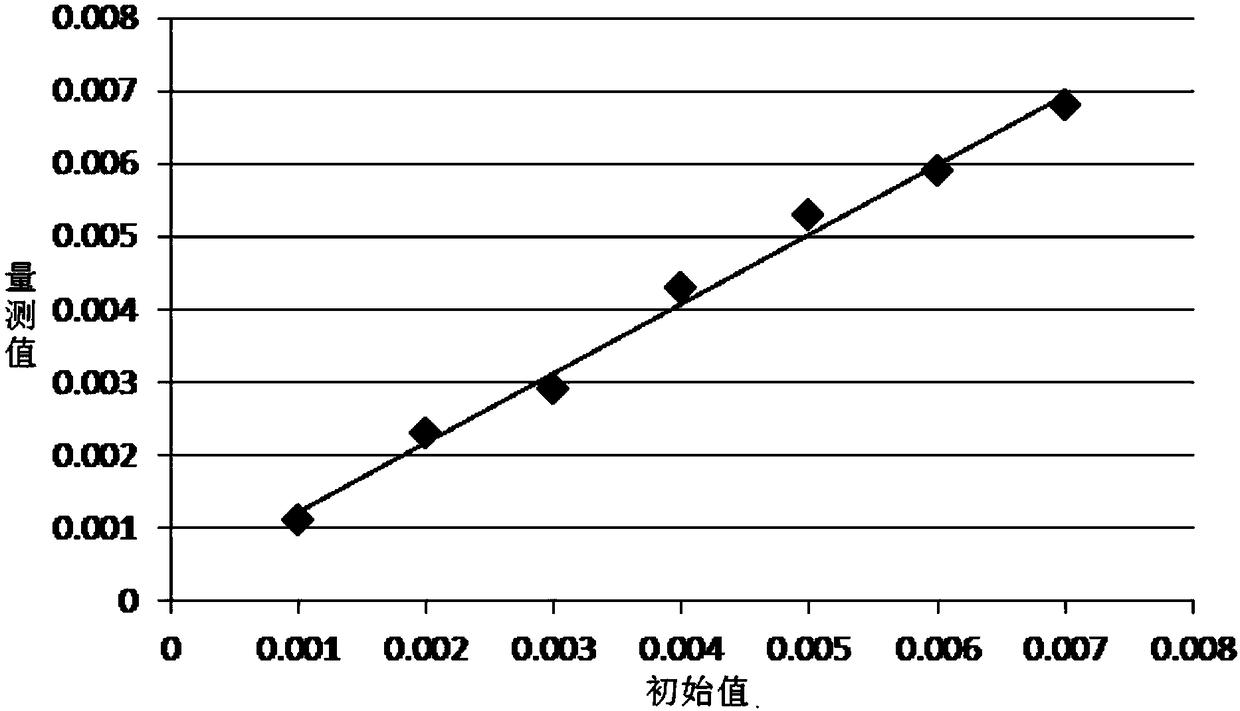

[0025] In order to solve the evaluation problem of lithographic overlay accuracy accuracy, the evaluation method of the present invention designs an overlay accuracy compensation value experiment, realizes it by exposure on an actual wafer, and then uses the overlay accuracy measurement method to be evaluated to measure, and The initial overlay accuracy compensation value is compared to determine whether the measurement method meets the measurement standard.

[0026] For the control flow of the evaluation method of the measurement accuracy of the lithography overlay precision, see figure 1 shown, including the following steps:

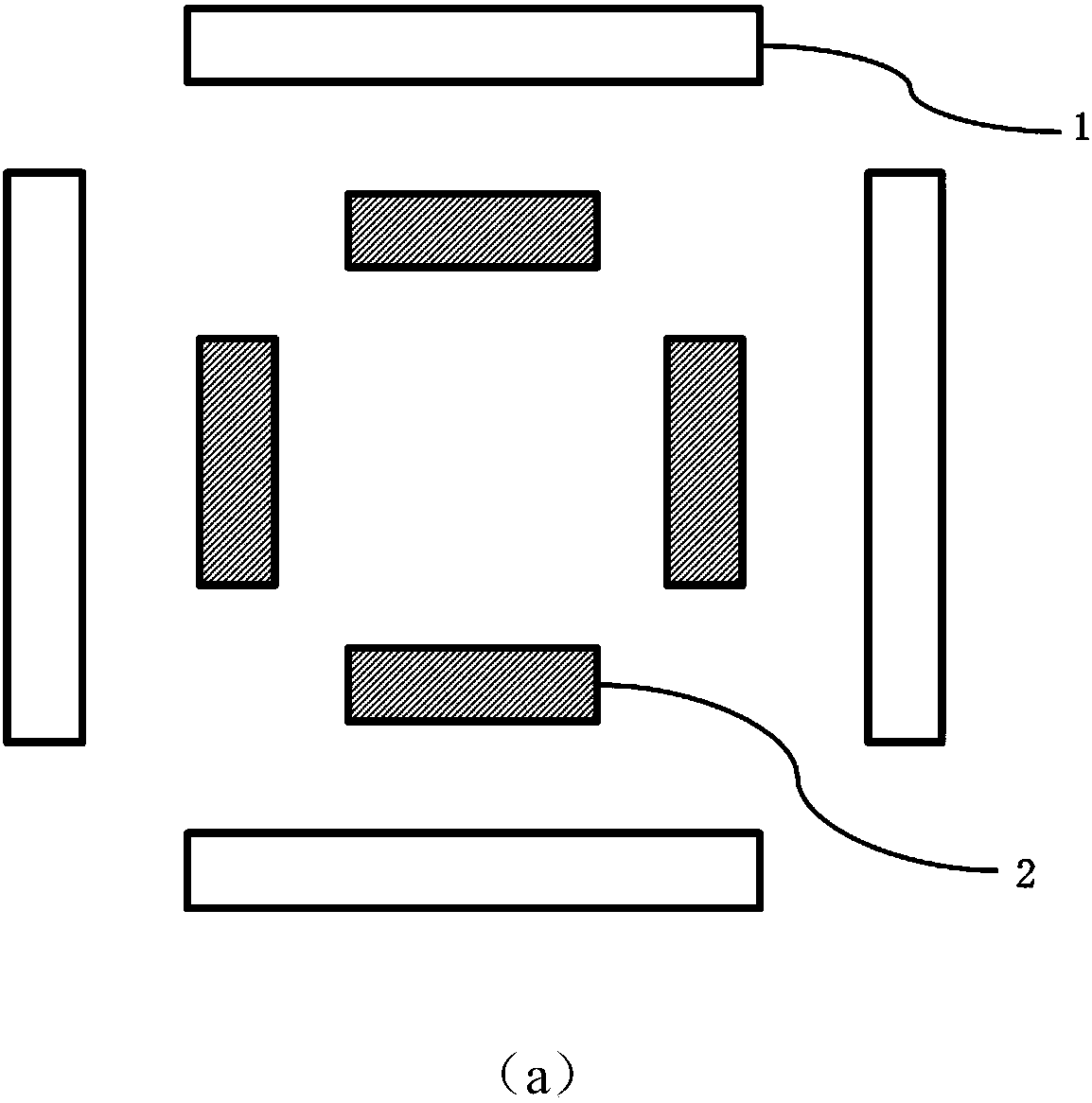

[0027] Step 1. Design the overlay accuracy measurement mark to be evaluated, and make it on the mask.

[0028] Step 2, forming a front-layer overlay pattern on the front-layer substrate through photolithography, etching and other processes;

[0029] Step 3. Perform on the wafer by giving the corresponding matrix series of overlay accuracy compensatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com