An optimization method for misjudgment of line marks by silicon wafer particle dust

An optimization method and technology of silicon wafers, applied in the direction of optical testing flaws/defects, etc., can solve problems such as large technical errors, achieve the effect of high degree of automation, strong practicability, and ensure scanning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

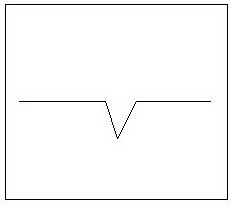

Image

Examples

Embodiment 1

[0018] A method for optimizing silicon chip particle dust misjudgment line marks, the specific steps of the silicon chip particle dust misjudgment line mark optimization method are as follows:

[0019] S1: The 3D laser scanner performs laser scanning on the silicon wafer, and 12 laser lines measure the line marks on the upper and lower sides of the silicon wafer respectively;

[0020] S2: The 3D laser scanner transmits the scanning information to the digital signal processor for analysis and processing to obtain the deviation data of the 12 laser lines at the line marks, and collects the data at the same time;

[0021] S3: The digital signal processor automatically numbers the data of the 12 laser lines, respectively numbered as measurement 1, measurement 2, measurement 3, measurement 4, measurement 5, measurement 6, measurement 7, measurement 8, measurement 9, measurement 10, measurement 11 and measure 12, obtain data 13, 12, 13, 12, 11, 12, 33, 13, 12, 44, 12 and 13, and cal...

Embodiment 2

[0025] A method for optimizing silicon chip particle dust misjudgment line marks, the specific steps of the silicon chip particle dust misjudgment line mark optimization method are as follows:

[0026] S1: The 3D laser scanner performs laser scanning on the silicon wafer, and 12 laser lines measure the line marks on the upper and lower sides of the silicon wafer respectively;

[0027] S2: The 3D laser scanner transmits the scanning information to the digital signal processor for analysis and processing to obtain the deviation data of the 12 laser lines at the line marks, and collects the data at the same time;

[0028] S3: The digital signal processor automatically numbers the data of the 12 laser lines, respectively numbered as measurement 1, measurement 2, measurement 3, measurement 4, measurement 5, measurement 6, measurement 7, measurement 8, measurement 9, measurement 10, measurement 11 and measure 12, obtain data 13, 12, 13, 12, 11, 12, 12, 13, 12, 44, 12 and 13, and cal...

Embodiment 3

[0032] A method for optimizing silicon chip particle dust misjudgment line marks, the specific steps of the silicon chip particle dust misjudgment line mark optimization method are as follows:

[0033] S1: The 3D laser scanner performs laser scanning on the silicon wafer, and 12 laser lines measure the line marks on the upper and lower sides of the silicon wafer respectively;

[0034] S2: The 3D laser scanner transmits the scanning information to the digital signal processor for analysis and processing to obtain the deviation data of the 12 laser lines at the line marks, and collects the data at the same time;

[0035] S3: The digital signal processor automatically numbers the data of the 12 laser lines, respectively numbered as measurement 1, measurement 2, measurement 3, measurement 4, measurement 5, measurement 6, measurement 7, measurement 8, measurement 9, measurement 10, measurement 11 and measure 12, obtain data 13, 12, 13, 12, 11, 12, 12, 13, 12, 13, 12 and 13, and cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com