Ultrahigh-toughness anti-blue light resin lens and preparation method thereof

A technology of resin lenses and modifiers, applied in the field of lenses, can solve the problem of not being able to filter blue light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

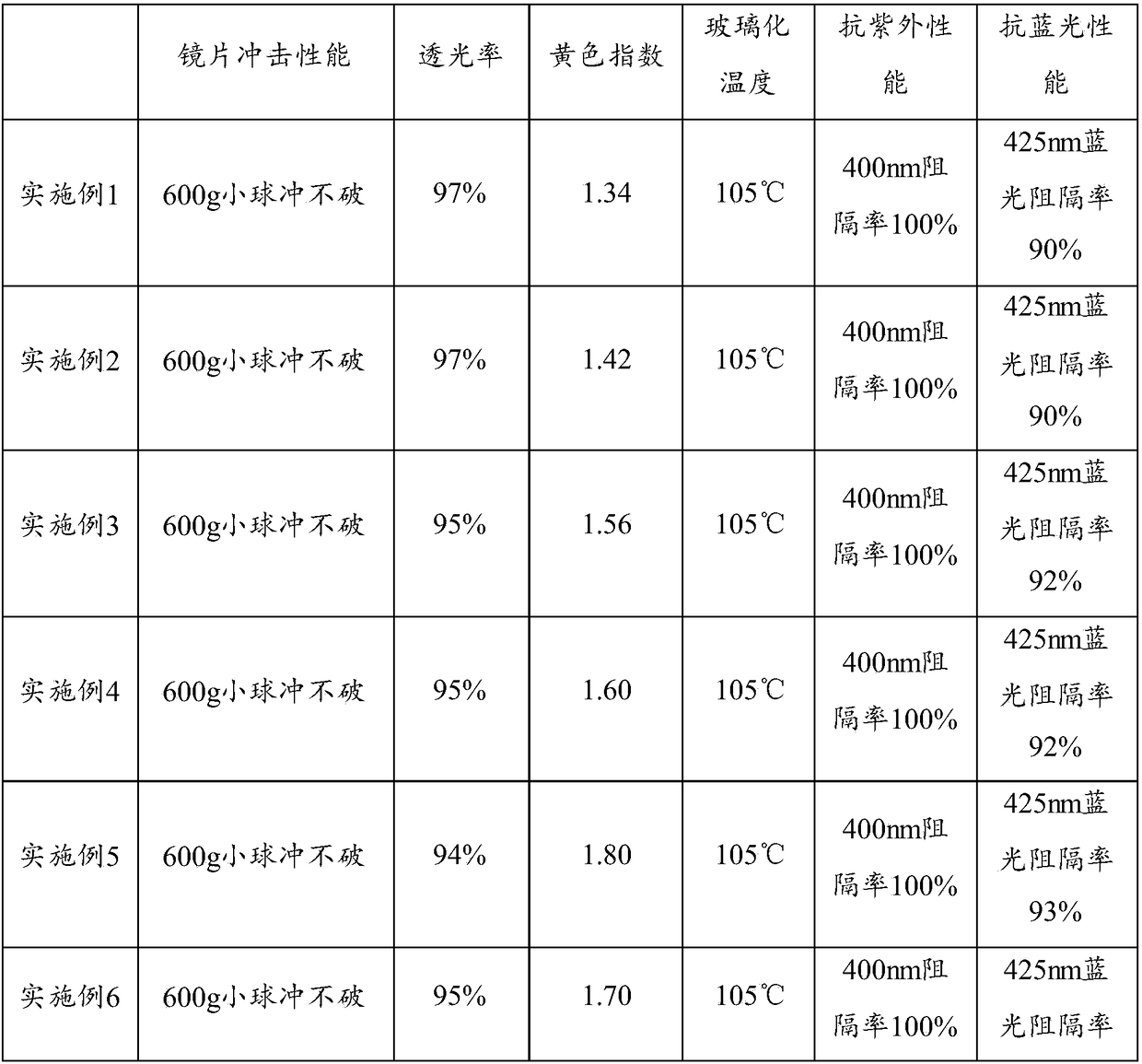

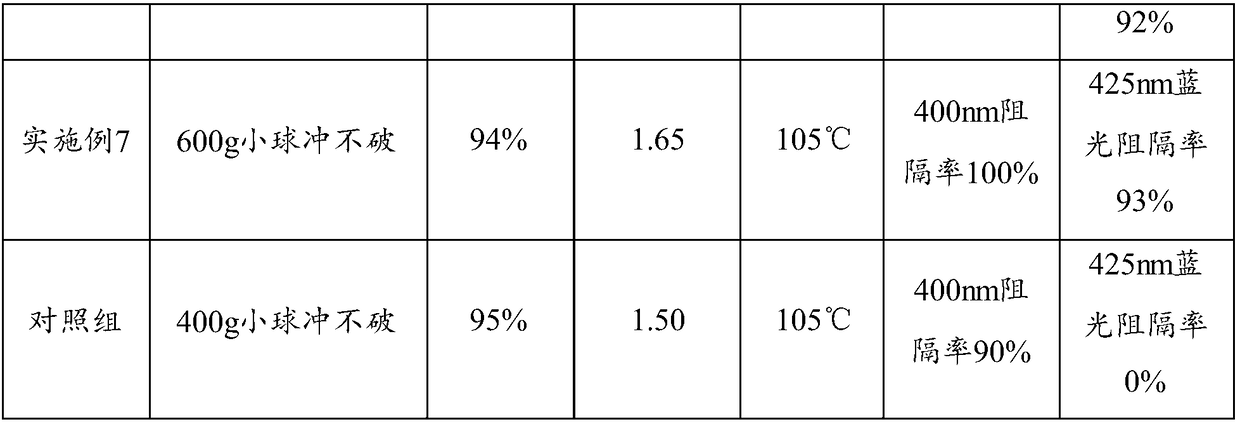

Examples

preparation example Construction

[0029] The raw materials for the preparation of resin lenses provided by the present invention include polyisocyanate; the polyisocyanate is preferably selected from 4,4-dicyclohexylmethane diisocyanate, isophorone diisocyanate, toluene diisocyanate, norbornane diisocyanate, hexaethylene diisocyanate, One or more of methyl diisocyanate and m-xylylene diisocyanate, more preferably selected from isophorone diisocyanate, hexamethylene diisocyanate, norbornane diisocyanate and m-xylylene diisocyanate One or more of isocyanates.

[0030] The raw materials for the resin lens provided by the invention include polythiol compounds. The polythiol compound is preferably selected from pentaerythritol tetrakis (3-mercaptopropionate), 2,3-di(2-mercaptoethylthio)-3-propane-1-thiol, thiodiglycol One or more of alcohol and thiodiglycol.

[0031] The raw materials for the resin lens provided by the invention include carboxylic acid compounds. The carboxylic acid compound is selected from one...

Embodiment 1

[0050] The consumption of raw material is as follows in the present embodiment:

[0051] Component A: Isophorone Diisocyanate (95g), Hexamethylene Diisocyanate (40g)

[0052] Component B: 2,3-bis(2-mercaptoethylthio)-3-propane-1-thiol (10 g)

[0053] Component C: Succinic acid (5g)

[0054] Component D: Tetrabromodiphenol-A (120g)

[0055] Modifier: methyl 3-[3-tert-butyl-4-hydroxy-5-(5-chloro-2H-benzotriazol-2-yl)phenyl]propionate (0.5g)

[0056] Release agent: DDP-8 (0.2g)

[0057] Catalyst: dibutyltin dichloride (0.2g)

[0058] specific steps

[0059] Weigh components A, C and catalyst in proportion, then mix them, stir at 15-20°C for 40-60 minutes, add a certain amount of modifier and release agent, and vacuum defoam for 30-40 minutes, the temperature 20-30°C; add components B and D, temperature 15-20°C, stir evenly for 40-60 minutes for vacuum defoaming, stop stirring, and vacuum defoam for 20 minutes. Dry nitrogen and pressurize, inject the mixed monomer into the ...

Embodiment 2

[0066] Component A: Hexamethylene diisocyanate (80g), norbornane diisocyanate (45g)

[0067] Component B: Pentaerythritol tetrakis(3-mercaptopropionate) (10g)

[0068] Component C: malonic acid (10g)

[0069] Component D: Tetrabromodiphenol-A (100g)

[0070] Modifier: 3-[3-(benzotriazol-2-yl)-5-tert-butyl-4-hydroxyphenyl]propionic acid (0.5g)

[0071] Release agent: DDP-2 (0.2g)

[0072] Catalyst: Trimethyltin Chloride (0.2g)

[0073] specific steps

[0074] Weigh components A, C and catalyst in proportion, then mix them, stir at 15-20°C for 40-60 minutes, add a certain amount of modifier and release agent, and vacuum defoam for 30-40 minutes, the temperature 20-30°C; add components B and D, temperature 15-20°C, stir evenly for 40-60 minutes for vacuum defoaming, stop stirring, and vacuum defoam for 20 minutes. Dry nitrogen and pressurize, inject the mixed monomer into the prepared mold through the filter membrane, after the pouring is completed, put the mold into the ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com