Acrylic plate for light guiding and production method thereof

A technology of acrylic sheet and acrylic resin, which is applied to the acrylic sheet for light guide and its production field, can solve the problems of poor mechanical properties, general light transmission performance, and reduce the degree of light decay, so as to improve the light transmittance and reduce the degree of light decay. , the effect of increased reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

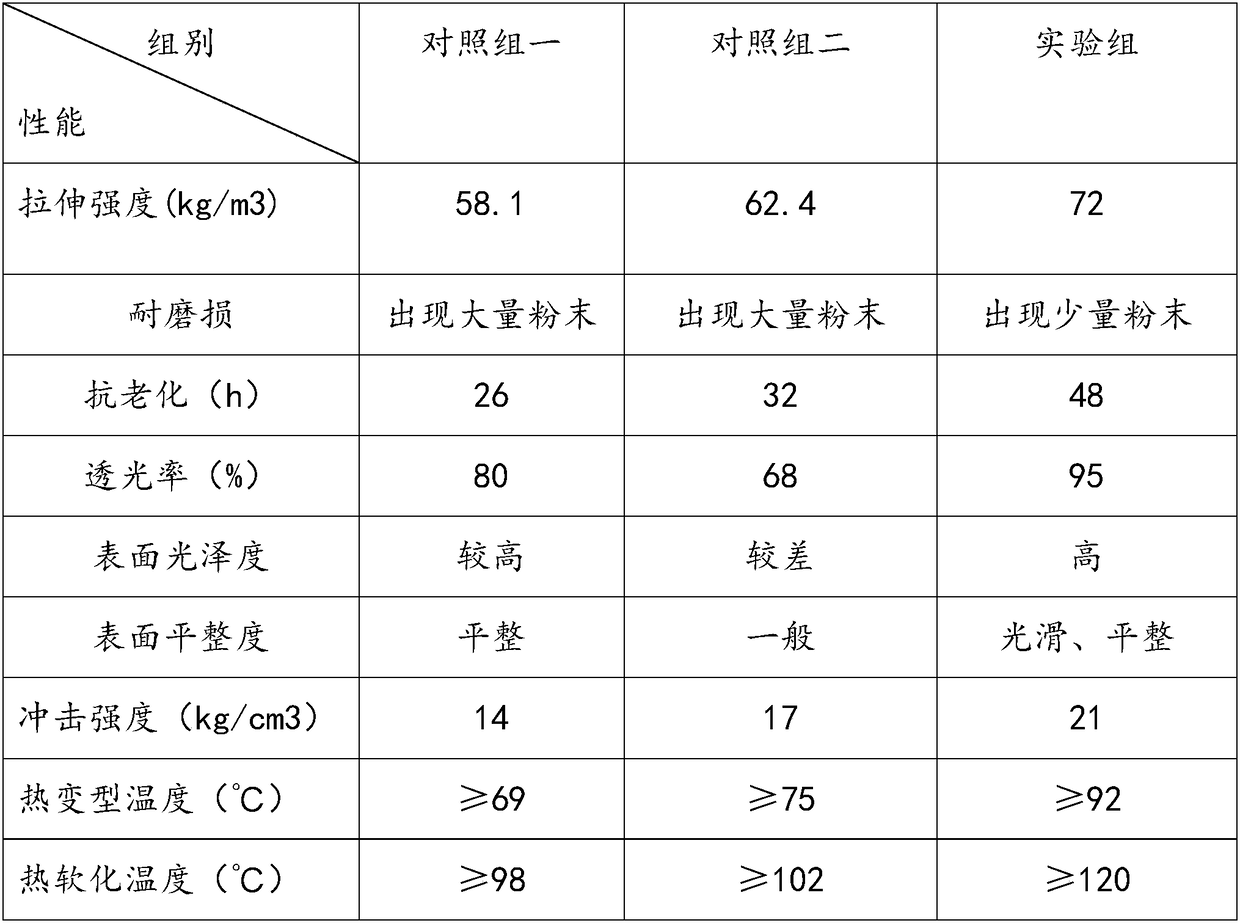

Examples

Embodiment 1

[0021] An acrylic sheet for light guide, made of the following raw materials in parts by weight: 50 parts of methyl methacrylate, 30 parts of acrylic resin powder, 4 parts of amine stearate, 9 parts of nano-silicone resin powder, 3 parts of azobisheptanol, 4 parts of talc, 5 parts of modified nano silica, 5 parts of chloromethyl acetate, 6 parts of sodium lauryl sulfate, 7 parts of calcium carbonate, 10 parts of styrene, pearl 2 parts of color paste, 5 parts of silicone oil, 7 parts of calcium lignosulfonate and 6 parts of hydroxypropyl methylcellulose.

[0022] A production method of acrylic sheet for light guide includes the following steps:

[0023] 1) Take 50 parts of methyl methacrylate and put it into the reaction kettle, and distill under reduced pressure in a vacuum state, and the vacuum pressure is between 0.8Mpa to obtain distilled methyl methacrylate for use;

[0024] 2) Take 30 parts of acrylic resin powder, 4 parts of amine stearate, 9 parts of nano silicone resin powde...

Embodiment 2

[0032] An acrylic sheet for light guide, made of the following raw materials in parts by weight: 40 parts of methyl methacrylate, 20 parts of acrylic resin powder, 2 parts of amine stearate, 6 parts of nano-silicone resin powder, 1 part of azobisisoheptarone, 2 parts of talc, 4 parts of modified nano silica, 3 parts of chloromethyl acetate, 4 parts of sodium lauryl sulfate, 5 parts of calcium carbonate, 8 parts of styrene, pearl 1 part of color paste, 3 parts of silicone oil, 5 parts of calcium lignosulfonate and 4 parts of hydroxypropyl methylcellulose.

[0033] A production method of acrylic sheet for light guide includes the following steps:

[0034] 1) Take 40 parts of methyl methacrylate and put it into the reaction kettle, and distill under reduced pressure in a vacuum state, and the vacuum pressure is between 0.3Mpa to obtain distilled methyl methacrylate, which is ready for use;

[0035] 2) Take 20 parts of acrylic resin powder, 2 parts of amine stearate, 6 parts of nano sil...

Embodiment 3

[0043] An acrylic sheet for light guide, made of the following raw materials in parts by weight: 45 parts of methyl methacrylate, 25 parts of acrylic resin powder, 3 parts of amine stearate, 7.5 parts of nano silicone resin powder, 2 parts azobisheptanol, 3 parts talc, 4.5 parts modified nano silica, 4 parts chloromethyl acetate, 5 parts sodium lauryl sulfate, 6 parts calcium carbonate, 9 parts styrene, pearlescent 1.5 parts of color paste, 4 parts of silicone oil, 6 parts of calcium lignosulfonate and 5 parts of hydroxypropyl methylcellulose.

[0044] A production method of acrylic sheet for light guide includes the following steps:

[0045] 1) Take 45 parts of methyl methacrylate and put it in the reaction kettle, and distill under reduced pressure in a vacuum state, and the vacuum pressure is between 0.5Mpa to obtain distilled methyl methacrylate, which is ready for use;

[0046] 2) Take 25 parts of acrylic resin powder, 3 parts of amine stearate, 7.5 parts of nano silicone resin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com