Silica sol hybrid hydroxyl acrylate emulsion and preparing method thereof

A technology of hydroxyacrylate and silica sol, which is applied in polyurea/polyurethane coatings, coatings, paints containing biocide, etc., can solve problems such as poor gloss and fullness, easy cracking of coating films, and large volume shrinkage , to achieve the effect of improving gloss and hardness, high adhesion, and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

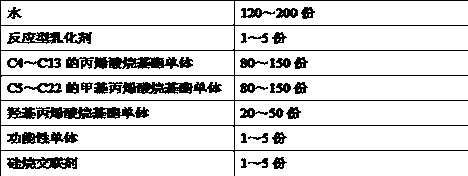

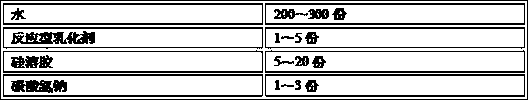

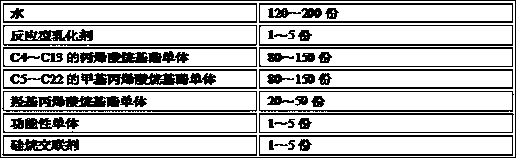

Method used

Image

Examples

Embodiment 1)

[0035] (1) Add 80g of water, 1g of allyloxynonylphenol polyoxyethylene ether ammonium sulfate, 20g of styrene, 100g of methyl methacrylate, and 1g of acrylic acid into the emulsification container with stirring in sequence and add it at 200r / min rotating speed to disperse at high speed to obtain pre-emulsion.

[0036] (2) Put 200g of water, 1g of allyloxynonylphenol polyoxyethylene ether ammonium sulfate, 100g of butyl acrylate, 150g of cyclohexyl methacrylate, 20g of hydroxyethyl acrylate, 3g of acrylic acid, and 1g of A-171 in order Add it into an emulsification container with stirring and disperse at a high speed of 200r / min to obtain a pre-emulsion.

[0037] (3) Add 2g of nonylphenol polyoxyethylene ether, 1g of allyloxynonylphenol polyoxyethylene ether ammonium sulfate, 5g of silica sol, 1g of sodium bicarbonate and 250g of water into a reaction vessel with stirring , stirring at a low speed of 50r / min and heating to 84°C, adding an aqueous solution containing 0.5g sodi...

Embodiment 2)

[0042] (1) Add 100g of water, 2g of allyloxy nonylphenol polyoxyethylene ether ammonium sulfate, 60g of styrene, 50g of butyl methacrylate, and 3g of acrylic acid into the emulsification container with stirring in order and turn it at 200r / min rotating speed to disperse at high speed to obtain pre-emulsion.

[0043](2), 150g of water, 2g of allyloxynonylphenol polyoxyethylene ether ammonium sulfate, 80g of isooctyl acrylate, 150g of octadecyl methacrylate, 50g of hydroxypropyl methacrylate, 5g of acrylic acid, Add 2g of A-174 into the emulsification container with stirring in order and disperse at a high speed of 200r / min to obtain a pre-emulsion.

[0044] (3) Add 3g of allyloxynonylphenol polyoxyethylene ether ammonium sulfate, 20g of silica sol, 1g of sodium bicarbonate and 250g of water into a stirred reaction vessel, stir at a low speed of 50r / min and Heat to 84°C and add an aqueous solution containing 0.5g sodium persulfate, and at the same time drop the pre-emulsion (1...

Embodiment 3)

[0049] (1) Add 120g of water, 2g of allyloxynonylphenol polyoxyethylene ether ammonium sulfate, 50g of styrene, 80g of isobornyl methacrylate, and 2g of acrylic acid into the emulsification container with stirring in order and 200r / min high-speed dispersion to obtain pre-emulsion.

[0050] (2) Put 160g of water, 2g of allyloxynonylphenol polyoxyethylene ether ammonium sulfate, 120g of isooctyl acrylate, 120g of methyl methacrylate, 40g of hydroxypropyl acrylate, 3g of acrylic acid, and 3g of A-174 in order Add it into an emulsification container with stirring and disperse at a high speed of 200r / min to obtain a pre-emulsion.

[0051] (3) Add 2g of allyloxy nonylphenol polyoxyethylene ether ammonium sulfate, 1g of allyloxy hydroxypropyl sulfonate, 10g of silica sol, 1g of sodium bicarbonate and 250g of water into a stirring tank In the reaction vessel, stir at a low speed of 50r / min and heat it to 84°C, add an aqueous solution containing 0.5g sodium persulfate, and add the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com