Preparation method of antibacterial and anti-thermal radiation aerogel

A technology of anti-thermal radiation and airgel, which is applied in the direction of ceramic products, applications, household appliances, etc., can solve the problems of easy breeding of bacteria, limit the application range of airgel materials in the field of heat insulation, and affect the service life, so as to achieve enhanced Anti-infrared heat radiation performance, good hydrodynamic performance, reasonable process design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

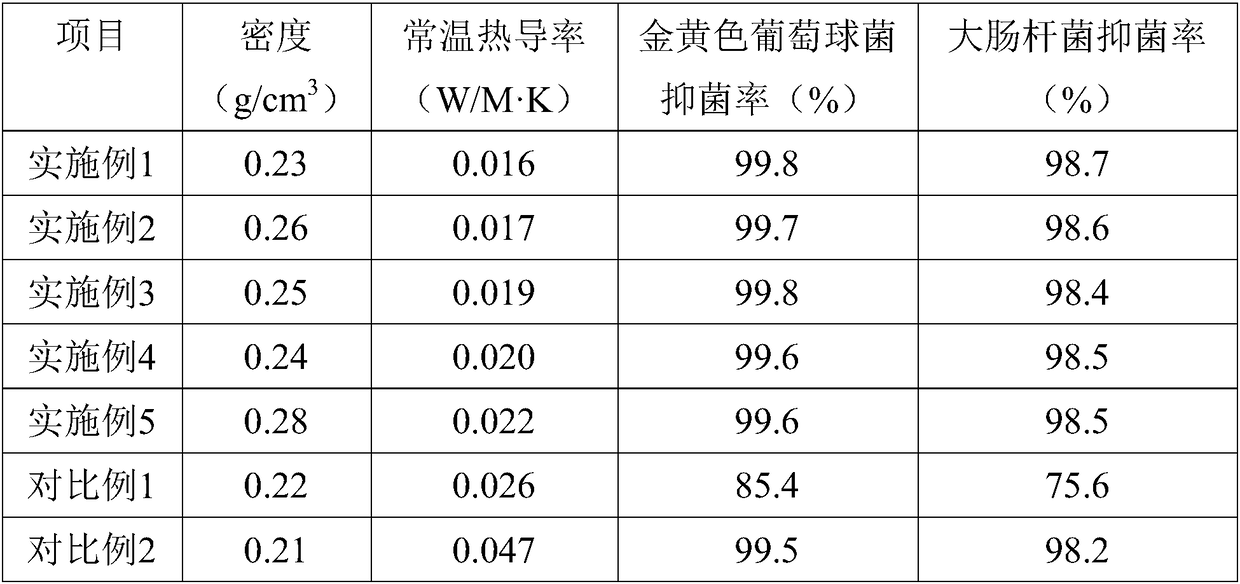

Examples

Embodiment 1

[0026] A preparation method of an antibacterial and anti-heat radiation airgel, comprising the following steps:

[0027] (1) Sol preparation: take 120g of sodium silicate and 1200g of ethanol to prepare sodium silicate solution; slowly add 6wt% hydrochloric acid solution to the sodium silicate solution to make the pH of the system reach 6.2, then add 96g of titanyl sulfate, and stir evenly at room temperature get sol;

[0028] (2) Preparation of mixed solution sol: add 169g of nano-titanium dioxide airgel micropowder to the sol, and use ultrasonic vibration for 30min to obtain mixed solution sol;

[0029] (3) Aging: inject the mixed liquid sol into the mold under vacuum, pre-aging at 56°C for 45 minutes, and then aging at room temperature for 23 hours to obtain a gel;

[0030] (4) Hydrothermal: Heat the gel water bath to 110°C and keep it warm until the titanium compound in the gel decomposes into metatitanic acid;

[0031] (5) Solution replacement: pump a mixture of acetone...

Embodiment 2

[0034] A preparation method of an antibacterial and anti-heat radiation airgel, comprising the following steps:

[0035] (1) Sol preparation: take 120g of sodium silicate and 850g of ethanol to prepare sodium silicate solution; slowly add 5wt% hydrochloric acid solution to the sodium silicate solution to make the pH of the system reach 6.5, then add 120g of titanyl sulfate, and stir evenly at room temperature get sol;

[0036] (2) Preparation of mixed solution sol: add an infrared radiation blocking agent with a sol mass of 258 g to the sol, and use ultrasonic vibration for 40 minutes to obtain a mixed solution sol;

[0037] (3) Aging: inject the mixed liquid sol into the mold under vacuum, pre-aging at 60°C for 40 minutes, and then aging at room temperature for 24 hours to obtain a gel;

[0038] (4) Hydrothermal: Heat the gel water bath to 115°C and keep it warm until the titanium compound in the gel decomposes into metatitanic acid;

[0039] (5) Solution replacement: pump ...

Embodiment 3

[0042] A preparation method of an antibacterial and anti-heat radiation airgel, comprising the following steps:

[0043](1) Sol preparation: take 120g of sodium silicate and 980g of ethanol to prepare sodium silicate solution; slowly add 5wt% hydrochloric acid solution to the sodium silicate solution to make the pH of the system reach 6.5, then add 83g of titanyl sulfate, and stir evenly at room temperature get sol;

[0044] (2) Preparation of the mixed solution sol: add 105 g of nano-silica airgel micropowder to the sol, and use ultrasonic vibration for 26 minutes to obtain the mixed solution sol;

[0045] (3) Aging: inject the mixed liquid sol into the mold under vacuum, pre-aging at 60°C for 42 minutes, and then aging at room temperature for 23 hours to obtain a gel;

[0046] (4) Hydrothermal: Heat the gel water bath to 106°C and keep it warm until the titanium compound in the gel decomposes into metatitanic acid;

[0047] (5) Solution replacement: pump the mixture of n-h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com