Method for treating organic chemical wastewater

A technology for chemical wastewater and wastewater, applied in chemical instruments and methods, water/sewage treatment, aerobic process treatment, etc., can solve the problems of high wastewater treatment process requirements and high treatment costs, and achieve easy control of the reaction, high activity, and stability good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] Preparation of microbial culture medium

[0067] The dried flour, blood meal and bone meal are mixed according to the mass fraction of 60% flour, 30% blood meal and 10% bone meal, and sieved to control the particle size below 0.1mm.

[0068] The activated carbon fiber is processed to 2-4mm, soaked in 60-68% nitric acid solution for 2-4 hours, washed with distilled water until neutral, and dried at 100°C to obtain the modified activated carbon fiber.

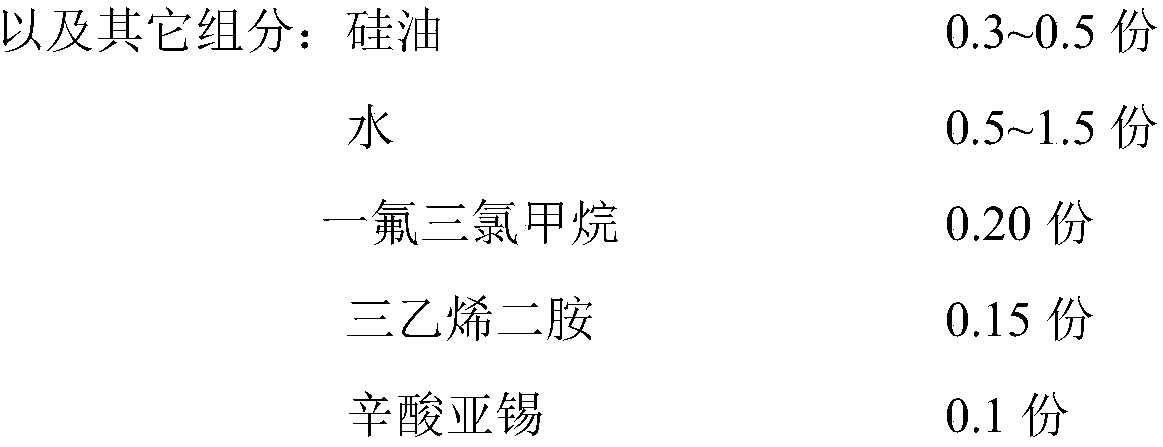

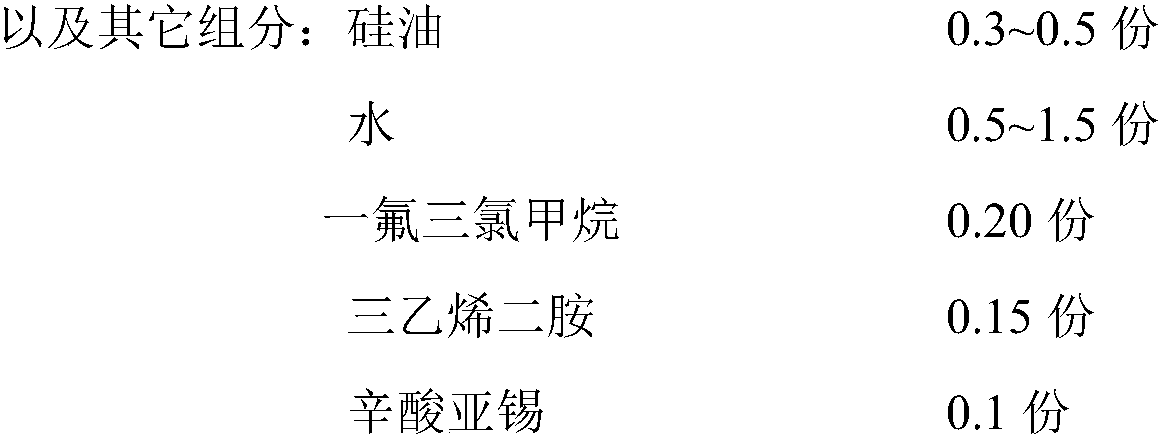

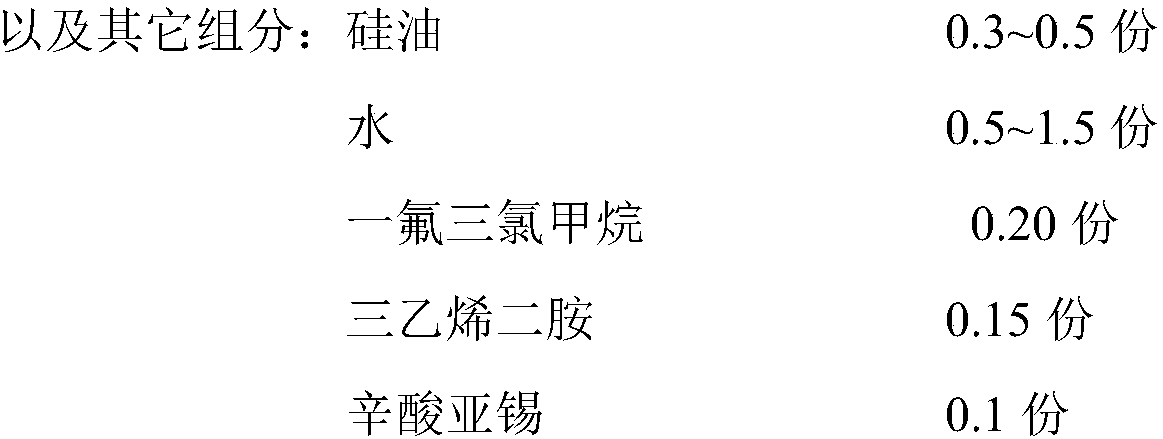

[0069] Preparation of Polyurethane Bioactive Carrier A

[0070] Component ①: polyether 330: 70-75 parts

[0071] Microbial culture medium 1.0~2.0 parts

[0072] After mixing the above raw materials in sequence, stir mechanically at 20°C for 10 minutes to obtain component ①.

[0073] Component ②: 25-30 parts of toluene diisocyanate

[0074] Modified activated carbon fiber 2.0~5.0 parts

[0075] After mixing the above raw materials in sequence, stir mechanically at 20°C for 10 minutes to obtain component ②.

[0076] ...

Embodiment 1

[0102] Add polyurethane bioactive carrier A and anaerobic microorganisms into the anaerobic reactor, and after 2 months of starting, the COD cr 30000mg / L, NH 4 + -N is 200mg / L Thymopentin processing and production wastewater is adjusted to neutral during the adjustment, the production wastewater after adjustment and homogenization enters the anaerobic reactor, reacts at 40°C for 72h, and measures the COD of the effluent cr 800mg / L, NH 4 + -N is 150mg / L. At this step, COD cr The removal rate is 97.33%, NH 4 + -N removal rate was 25%.

[0103] The water quality treated in the anaerobic reactor is re-entered into the aerobic reactor, and immobilized microbial carrier A and microorganism B350 (BIO-SYSTEM, USA) are added to the aerobic reactor, and reacted at 30°C for 24h , measured water COD cr 100mg / L, NH 4 + -N is 20mg / L. At this step, COD cr The removal rate is 87.5%, NH 4 + -N removal rate is 86.67%.

[0104]The water quality after the treatment in the aerobic ...

Embodiment 2

[0107] Add polyurethane bioactive carrier B into the anaerobic reactor, add polyurethane bioactive carrier A and anaerobic microorganisms into the anaerobic reactor, and after 2 months of starting, the COD cr 30000mg / L, NH 4 + -N is 200mg / L Thymopentin processing and production wastewater is adjusted to neutral during the adjustment, the production wastewater after adjustment and homogenization enters the anaerobic reactor, reacts at 40°C for 72h, and measures the COD of the effluent cr 1200mg / L, NH 4 + -N is 150mg / L. At this step, COD cr The removal rate is 96%, NH 4 + -N removal rate was 25%.

[0108] The water quality treated in the anaerobic reactor is re-entered into the aerobic reactor, and immobilized microbial carrier A and microorganism B350 (BIO-SYSTEM, USA) are added to the aerobic reactor, and reacted at 30°C for 24h , measured water COD cr 500mg / L, NH 4 + -N is 100mg / L. At this step, COD cr The removal rate was 58.33%, NH 4 + -N removal rate was 30%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com