Method for preparing single-layer two-dimensional transition metal sulfide material

A transition metal and sulfide technology, applied in the field of preparing single-layer two-dimensional transition metal sulfide materials, can solve problems such as pollution, sample contamination, and excessive crystal nuclei

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] use as figure 1 The CVD growth equipment, the components 1, 2, 3 and 4 in the figure, the areas 1 and 2 are the low temperature zone and the high temperature zone of CVD respectively, 1 is S powder or Se powder, 2 is metal foil, and 3 is sapphire substrate , 4 for Ar and H 2 of mixed gas.

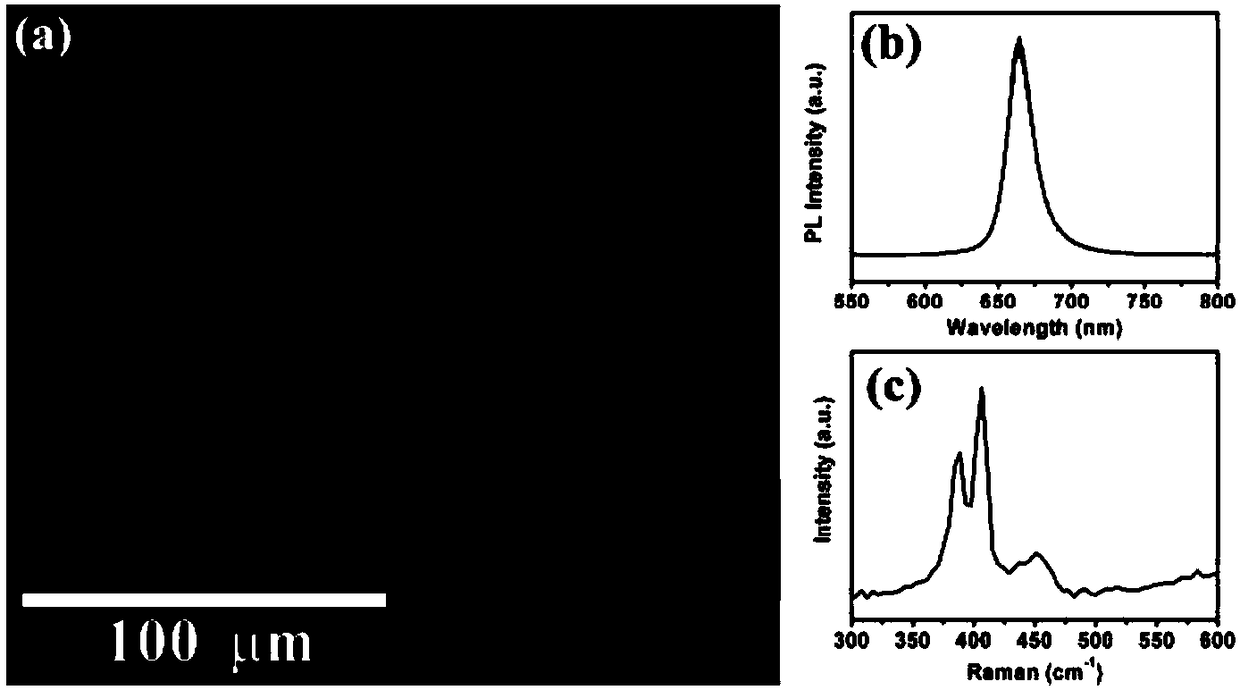

[0027] A preparation of monolayer MoS 2 Methods. Include the following steps:

[0028] (1), at first, Mo metal foil is in the mixed solution of concentrated sulfuric acid and hydrogen peroxide (H 2 SO 4 :H 2 o 2 Volume ratio=2:1) soaking for 2 hours, then place the Mo metal foil at 2 places in the high temperature zone 2 of the 2-inch quartz tube, raise the temperature to 400 °C at a speed of 40 °C / min, and conduct the M metal foil Normal pressure annealing treatment in air for 2 minutes to fully oxidize it to Mo oxide MoO 3-X ;

[0029] (2), put the cut 10*40mm single throwing quartz plate in the mixed solution of concentrated sulfuric acid and hydrogen peroxide (H 2 SO...

Embodiment 2

[0034] use as figure 1 The CVD growth equipment in the figure, components 1, 2, 3 and 4 in the figure, areas 1 and 2 are the low temperature zone and high temperature zone of CVD respectively, 1 is Se powder, 2 is metal foil, 3 is sapphire substrate, 4 is Ar and H 2 of mixed gas.

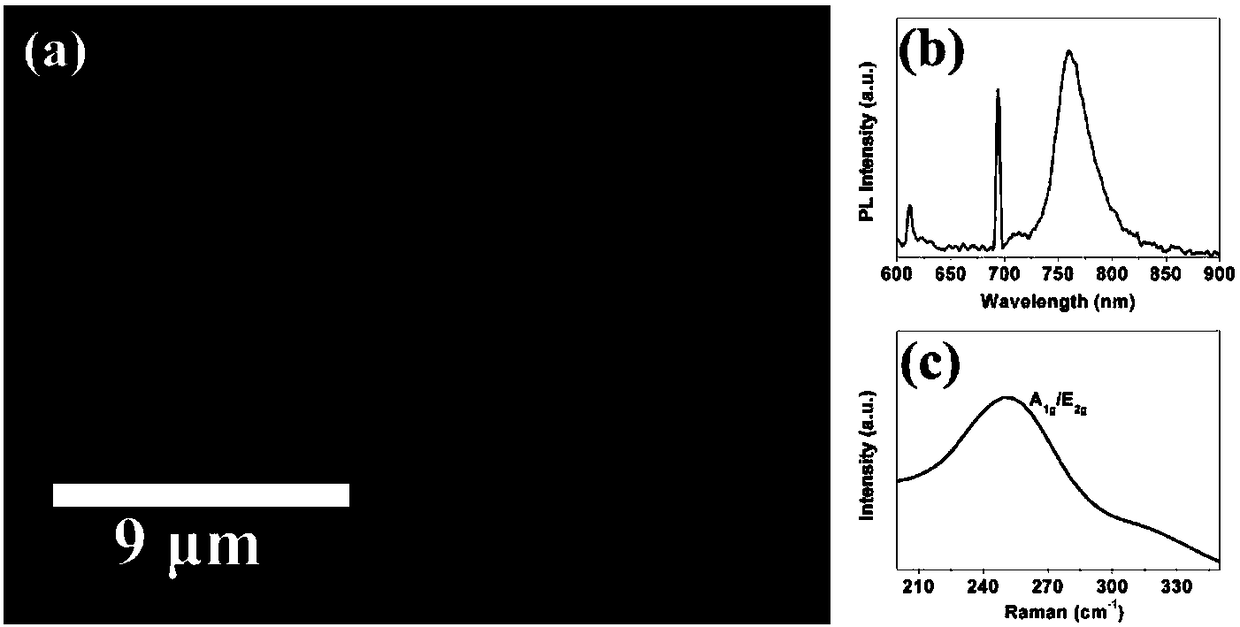

[0035] A preparation of monolayer WSe 2 Methods. Using the oxidized W foil as the W precursor and Se powder as the Se source, the triangular WSe with a side length of about 4.5 microns was prepared. 2 . Using optical microscope and Raman equipment to characterize the prepared samples, the results are as follows image 3 shown. The sample presents a very good triangular shape and is a monolayer WSe with good uniformity 2 Material. Specific steps are as follows:

[0036] (1), first, put W metal foil in the mixed solution of concentrated sulfuric acid and hydrogen peroxide (H 2 SO 4 :H 2 o 2 Volume ratio=2:1) soaking for 2 hours, then place the W metal foil at 2 places in the high temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com