A preparation method of nanometer calcium hydroxide powder material used for reinforcement of ancient murals

A technology of calcium hydroxide and powder materials, applied in calcium/strontium/barium oxide/hydroxide, nanotechnology, preserved painting, etc., can solve the problems of long time consumption and high energy consumption, and achieve low energy consumption and synthesis The effect of low cost and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

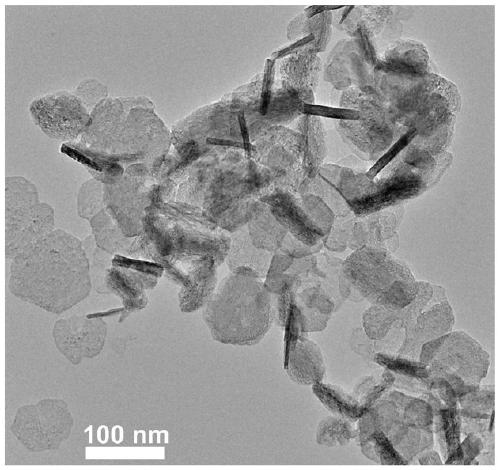

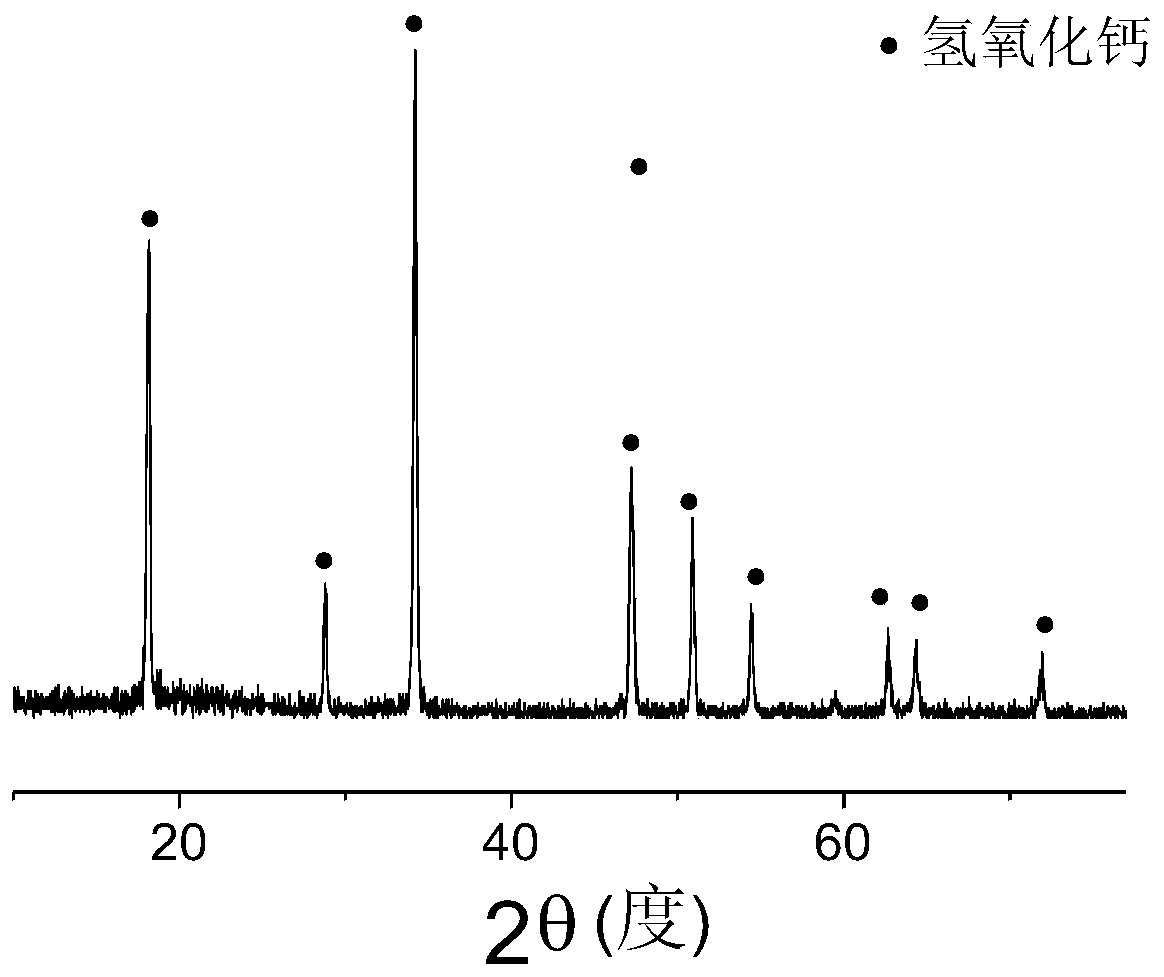

Image

Examples

Embodiment 1

[0026] At 20°C, 5% dimethylformamide was added to the calcium chloride solution and stirred on a magnetic stirrer for 3 minutes. Pour the stirred calcium chloride solution into the prepared sodium hydroxide solution to synthesize nano calcium hydroxide. Wherein the molar ratio of calcium chloride and sodium hydroxide is 1:2. The synthesized nano calcium hydroxide was washed 3 times with saturated lime water. After washing, dry at 45°C for 6 hours to obtain nanometer calcium hydroxide powder.

[0027] Test Results:

[0028] 50% increase in peel strength: Permeability: 2 minutes, artificial weathering resistance 1000 hours mural without any change.

[0029] Dissolving nano calcium hydroxide powder in ethanol to form a solution, and painting the prepared solution on ancient murals; the concentration range of nano calcium hydroxide dissolved in ethanol is 3-5mg / ml.

Embodiment 2

[0031] At 22 degrees, dimethylformamide with a mass fraction of 6% was added to the calcium chloride solution and placed on a magnetic stirrer to stir for 4 minutes. Pour the stirred calcium chloride solution into the prepared sodium hydroxide solution to synthesize nano calcium hydroxide. Wherein the molar ratio of calcium chloride and sodium hydroxide is 1:2. The synthesized nano calcium hydroxide was washed 3 times with saturated lime water. After washing, dry at 50°C for 8 hours to obtain nanometer calcium hydroxide powder.

[0032] Test Results:

[0033] 48% increase in peel strength: Permeability: 1.8 minutes, 1000 hours of artificial weathering resistance mural without any change.

[0034] Dissolving nano calcium hydroxide powder in ethanol to form a solution, and painting the prepared solution on ancient murals; the concentration range of nano calcium hydroxide dissolved in ethanol is 3-5mg / ml.

Embodiment 3

[0036] Under the condition of 24 degrees, dimethylformamide with a mass fraction of 8% was added to the calcium chloride solution and placed on a magnetic stirrer to stir for 5 minutes. Pour the stirred calcium chloride solution into the prepared sodium hydroxide solution to synthesize nano calcium hydroxide. Wherein the molar ratio of calcium chloride and sodium hydroxide is 1:2. The synthesized nano calcium hydroxide was washed 4 times with saturated lime water. After washing, dry at 55°C for 9 hours to obtain nanometer calcium hydroxide powder.

[0037] Test Results:

[0038] Anti-peel strength increased by 53%: Permeability: 1.9 minutes, artificial weathering resistance 1000 hours mural without any change.

[0039] Dissolving nano calcium hydroxide powder in ethanol to form a solution, and painting the prepared solution on ancient murals; the concentration range of nano calcium hydroxide dissolved in ethanol is 3-5mg / ml.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com