Inorganic-cellulose composite carbon aerogel and preparation method thereof

A technology of cellulose airgel and carbon airgel, which is applied in the direction of airgel preparation, carbon preparation/purification, chemical instruments and methods, etc., can solve the problems that cannot meet the needs of energy storage and conversion devices, few active sites, Poor mechanical properties and other problems, to achieve the effect of solvent green environmental protection, good conductivity and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

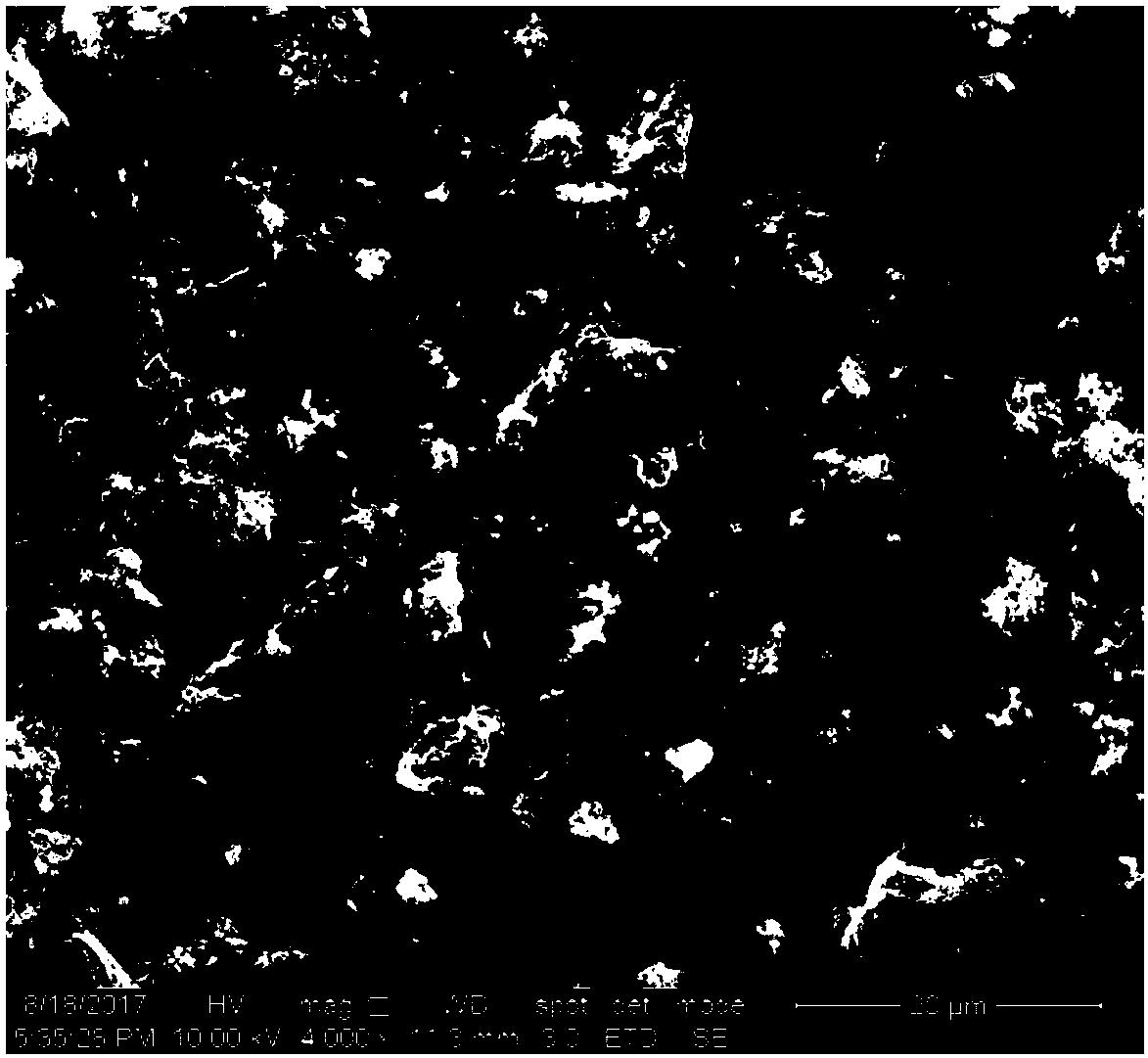

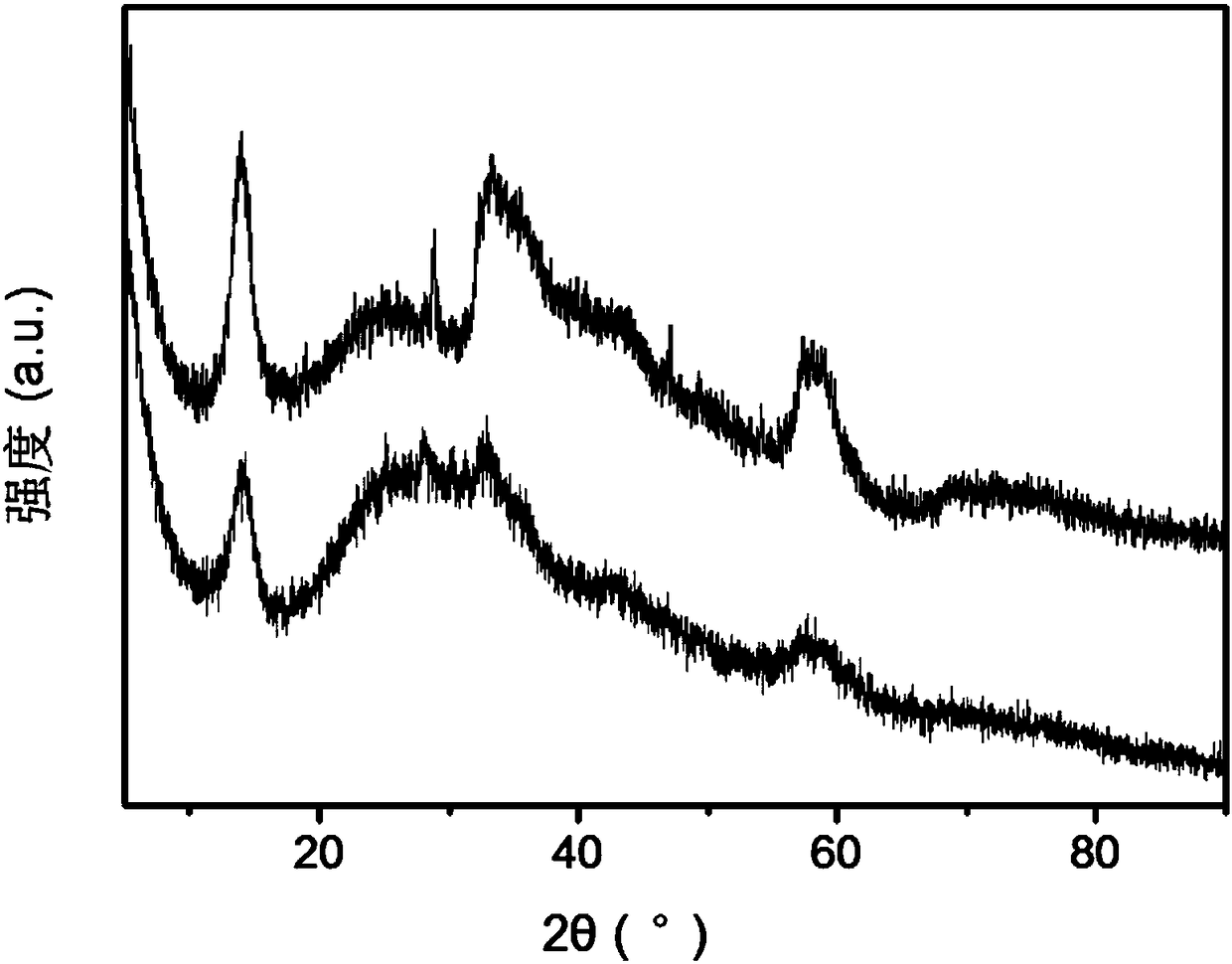

[0038] A preparation method of inorganic-cellulose composite carbon aerogel includes the following steps:

[0039] 1) Prepare a 0.01wt% sulfuric acid modified cellulose nanocrystal dispersion, and then use an ultrasonic pulverizer with a power of 300-1800W to perform ultrasonic treatment for 60 minutes to obtain a uniform dispersion;

[0040] 2) Put the dispersion obtained in step 1) into a dialysis bag with a molecular weight of 8000-14000, then soak the dialysis bag in tert-butanol and place it in tert-butanol for 24 hours, and use a magnetic stirrer for mechanical stirring , Until the volume of the remaining suspension is 1 / 3 of the original volume, collect the remaining suspension and put it in a bottle and freeze it in an ultra-low temperature refrigerator at -55℃ for 24h; then transfer to the conditions of a vacuum of 0.1μpa-100pa and -80℃ Dry for 72h; get sulfuric acid modified cellulose aerogel;

[0041] 3) Put the sulfuric acid-modified cellulose aerogel into a tube furnace...

Embodiment 2

[0047] A preparation method of inorganic-cellulose composite carbon aerogel includes the following steps:

[0048] 1) Prepare a 0.01wt% TEMPO modified cellulose nanocrystal dispersion, and then use an ultrasonic pulverizer with a power of 300-1800W to perform ultrasonic treatment for 60 minutes to obtain a uniform dispersion;

[0049] 2) Put the dispersion obtained in step 1) into a dialysis bag with a molecular weight of 8000-14000, then soak the dialysis bag in tert-butanol and place it in tert-butanol for 24 hours, and use a magnetic stirrer for mechanical stirring , Until the volume of the remaining suspension is 1 / 3 of the original volume, collect the remaining suspension and put it in a bottle and freeze it in an ultra-low temperature refrigerator at -55℃ for 24h; then transfer to the conditions of a vacuum of 0.1μpa-100pa and -80℃ Dry for 72h; get TEMPO modified cellulose aerogel;

[0050] 3) Put the TEMPO-modified cellulose aerogel into a tube furnace, and then heat the tube...

Embodiment 3

[0057] A preparation method of inorganic-cellulose composite carbon aerogel includes the following steps:

[0058] 1) Prepare a 0.01wt% hydrochloric acid modified cellulose nanocrystal dispersion, and then use an ultrasonic pulverizer with a power of 300-1800W to perform ultrasonic treatment for 60 minutes to obtain a uniform dispersion;

[0059] 2) Put the dispersion obtained in step 1) into a dialysis bag with a molecular weight of 8000-14000, then soak the dialysis bag in tert-butanol and place it in tert-butanol for 24 hours, and use a magnetic stirrer for mechanical stirring , Until the volume of the remaining suspension is 1 / 3 of the original volume, collect the remaining suspension and put it in a bottle and freeze it in an ultra-low temperature refrigerator at -55℃ for 24h; then transfer to the conditions of a vacuum of 0.1μpa-100pa and -80℃ Dry for 72h; get hydrochloric acid modified cellulose aerogel

[0060] 3) Put the hydrochloric acid-modified cellulose aerogel into a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com