Powder-coated composite material horizontal bar

A composite material and powder coating technology, applied in the field of sports equipment, can solve the problem of single assembly method of the horizontal bar and the bar head, and achieve the effects of strong comfort, preventing athletes from falling, and high safety factor against crack expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

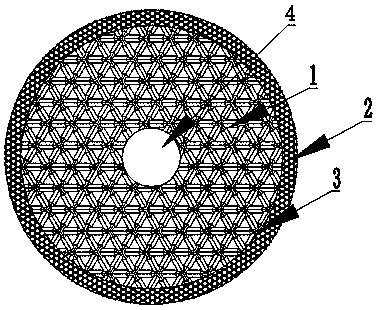

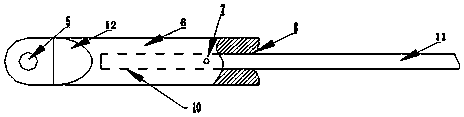

[0022] Use M40 grade carbon fiber, T700 grade carbon fiber woven cloth with an outer covering surface density of 50-200g / ㎡, and the innermost layer of high toughness material. After molding, the fiber-reinforced thermosetting resin-based composite material round rod 1 and the inner high-toughness material region 4 are produced by pultrusion or molding process, wherein the fiber volume content in the fiber-reinforced thermosetting resin-based composite material round rod 1 is 45%-75%, wherein the circumferential fiber accounts for 0-10% of the total fiber content, and the elastic modulus of the fiber-reinforced thermosetting resin matrix composite rod 1 is between 150GPa-260GPa. Then the fiber-reinforced thermosetting resin-based composite material round rod 1 is subjected to sandblasting, polishing or grinding to roughen the surface, and the surface of the fiber-reinforced thermosetting resin-based composite material round rod 1 is cleaned with a cloth dipped in a solvent, and ...

Embodiment 2

[0024] Use M46 grade carbon fiber, T700 grade carbon fiber woven cloth with an outer covering surface density of 50-200g / ㎡, and the innermost layer is a high-toughness material. In this embodiment, the high-toughness material is preferably aramid fiber. After molding, the fiber-reinforced thermosetting resin-based composite material round rod 1 and its internal high-toughness material area 4 are produced by stretching and winding process, wherein the fiber volume content in the fiber-reinforced thermosetting resin-based composite material round rod 1 is 50% -75%, wherein the circumferential fibers account for 5%-10% of the total fiber content, and the elastic modulus of the fiber-reinforced thermosetting resin matrix composite rod 1 is between 150GPa-260GPa. The fiber-reinforced thermosetting resin-based composite material round rod 1 is roughened by sandblasting, polishing or grinding, etc., and the surface of the fiber-reinforced thermosetting resin-based composite material r...

Embodiment 3

[0026] Use M46 grade carbon fiber, T700SC carbon fiber unidirectional prepreg and high-strength carbon fiber to produce fiber-reinforced thermosetting resin matrix composite rod 1 and its internal high-toughness material area 4, in which high-strength carbon fiber is used as high-toughness material Filled in the high-toughness material area 4, the fiber volume content in the fiber-reinforced thermosetting resin-based composite material round rod 1 made is 75%, wherein the circumferential fibers account for 10% of the total fiber content, and the fiber-reinforced thermosetting resin-based composite material round rod The elastic modulus of 1 is between 150GPa-260GPa. The prepared fiber-reinforced thermosetting resin-based composite material round rod 1 is treated by sandblasting, polishing or grinding to roughen the surface of the fiber-reinforced thermosetting resin-based composite material round rod 1, and the fiber-reinforced thermosetting resin-based composite material is cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com