Low-resistance-drop filtering material and preparation method thereof

A filter material and resistance drop technology, applied in the fields of porous materials, high flux filter materials, and high temperature flue gas filtration, it can solve the problems of limited gas processing capacity, large filter area, and small flux, and achieve small resistance drop, high Filtration precision, high-throughput effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

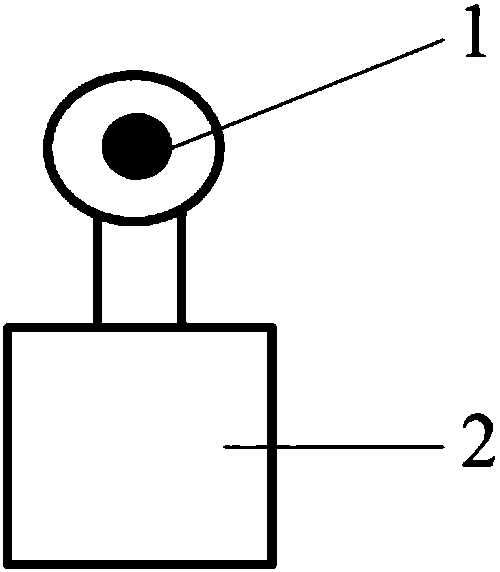

[0044] Embodiment 1 tubular filter material preparation

[0045] (1) Tubular base material rolling: the multi-layer composite FeCrAl fiber mat with a size of 157mm×1000mm×1mm (the average pore diameter is 22.50μm and the permeability is 5.43×10 -4 L / Pa.min.cm 2 ) is rolled into a tube shape along the width direction on the rolling equipment, and a seam is formed along the length direction;

[0046] (2) Tubular base material welding: the seam formed by the fiber mat rolled into a tubular shape obtained in step (1) is welded with argon arc welding to obtain a tubular base material, and the tube size is Φ50mm×1000mm (length)×1mm (pipe wall thickness);

[0047] (3) Preparation of spraying liquid: Fe-Al alloy powder prepared by -500 mesh water mist method (ingredient distribution ratio: Al content 15wt%, Cr content 4%, B content 0.04%, Zr content 0.15%, surplus is Fe) and glue are fully mixed to obtain metal powder suspension, i.e. spraying liquid; wherein, the proportion of all...

Embodiment 3

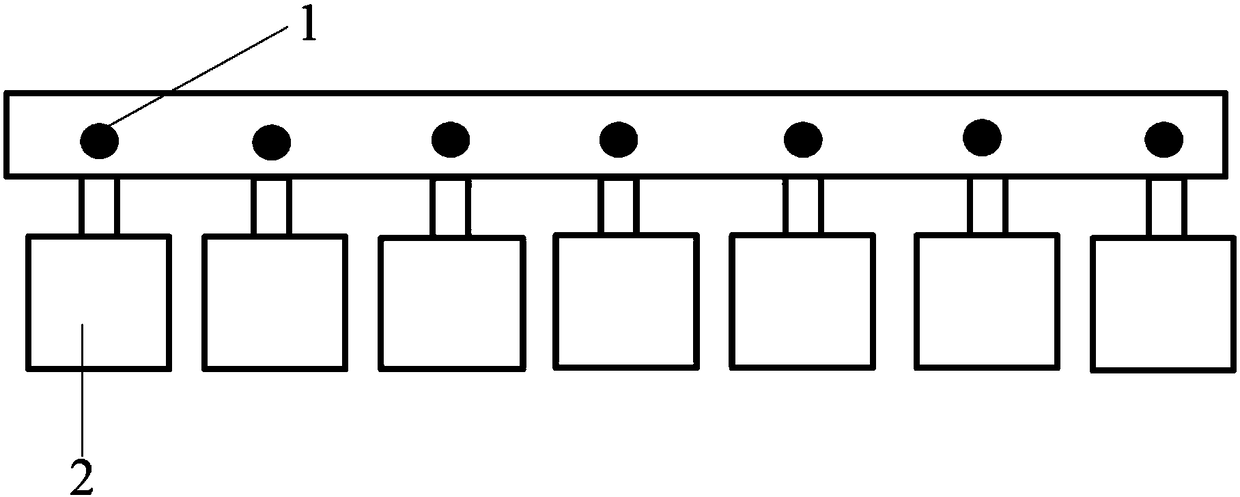

[0062] Embodiment 3 plate type filter material preparation

[0063] (1) Plate-type base material selection: a plate-type multi-layer composite FeCrAl fiber mat with a size of 500mm×500mm×0.5mm (length×width×thickness) (the average pore size detected by the PMI gas permeation method pore size analyzer is 15.02 μm, The permeability is 1.01×10 - 3 L / (Pa.min.cm 2 )) as a board-type substrate;

[0064] (2) Spraying solution preparation: fully mix -500 mesh NiCrAlFe powder (ingredient distribution ratio: Al content 4.5wt%, Cr content 16wt%, Fe content 4wt%, remainder is Ni) and glue solution fully mix, obtain metal powder suspension Liquid, that is, spraying liquid; wherein, the proportion of powder is 50%; the composition of glue liquid is acetone, epoxy resin and ethylenediamine, and the mass ratio of preparation is 14:3:3;

[0065] (3) Plate substrate spraying: combine the spray guns according to the length of the plate substrate (see figure 2 ), so that the spraying range ...

Embodiment 4

[0069] The preparation method of the filter material of this embodiment is the same as that of embodiment 1 except that the formula of the spraying liquid is different from the step (3) of embodiment 1. Present embodiment step (3) is detailed as follows:

[0070] Spraying solution preparation: Fe-Al alloy powder prepared by -500 mesh water mist method (ingredient distribution ratio: Al content 15wt%, Cr content 4%, B content 0.04%, Zr content 0.15%, the balance is Fe) and The glue is fully mixed to obtain a metal powder suspension, i.e. a spraying liquid; wherein, the proportion of the alloy powder is 75%; the glue components are acetone, epoxy resin and ethylenediamine, and the mass ratio of the above three components in the glue is 21:3:1. As the proportion of acetone increases, the viscosity of the glue decreases, and the formed metal powder suspension is unstable, and the metal powder is prone to sedimentation, resulting in uneven spray coating.

[0071] The membrane thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com