Processing method of flat high-aroma spring mulberry leaf green tea

A processing method and high-flavor technology, applied in the processing field of flat high-flavor spring mulberry leaf green tea, can solve problems such as single aroma, dark yellow soup, bitter taste, etc., and achieve the effect of simple processing method and continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

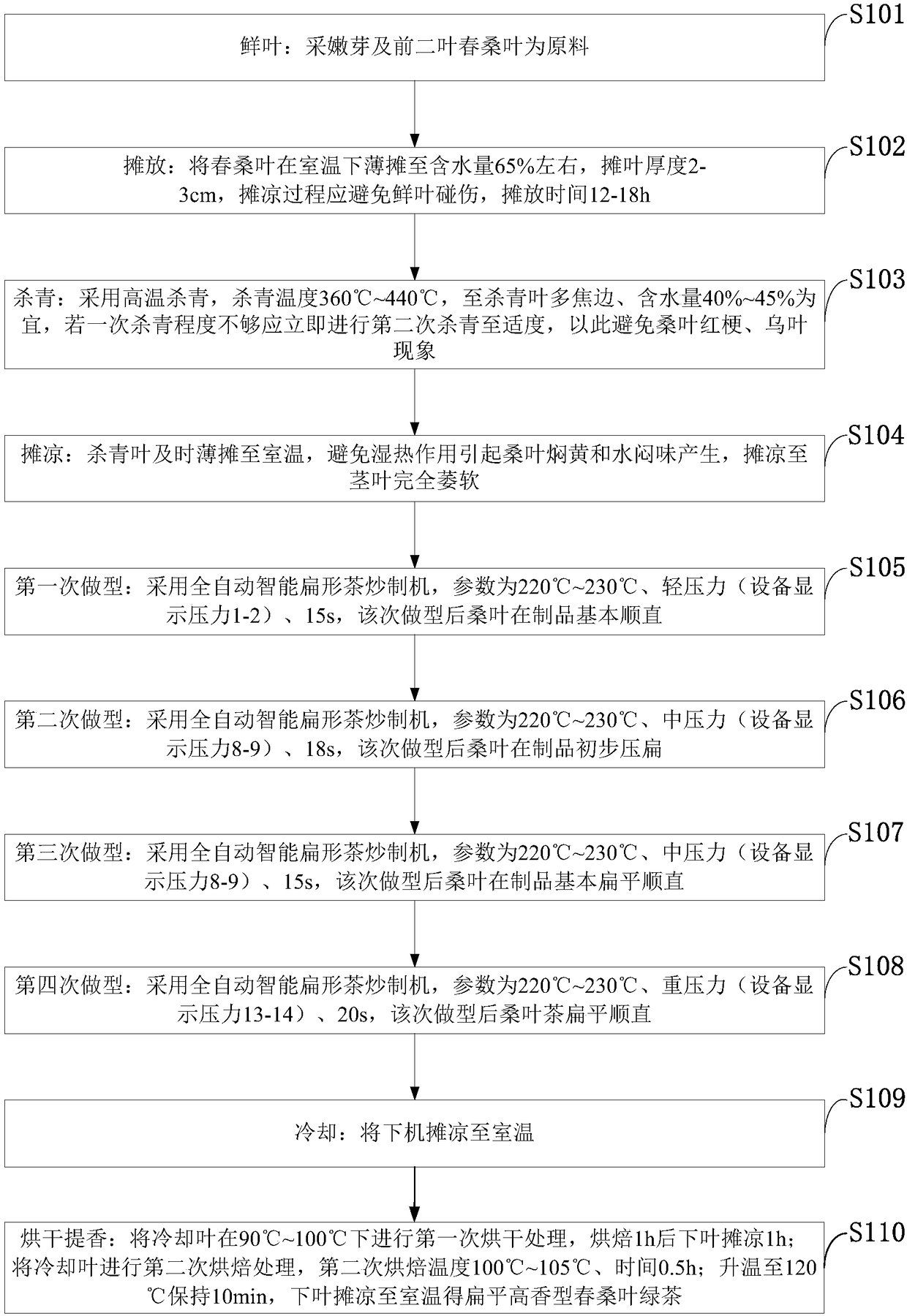

Image

Examples

Embodiment 1

[0037] (1) Fresh leaves: picking young shoots and the first two spring mulberry leaves as raw materials;

[0038] (2) Spreading: spread the spring mulberry leaves thinly at room temperature until the water content is 60%-63%, the leaf thickness is 2-3cm, and the fresh leaves should be avoided during the cooling process, and the spreading time is 15h;

[0039] (3) Finishing: use a drum fixing machine, the fixing temperature is 360°C to 400°C, and the water content of the leaves is 42% to 45%;

[0040] (4) Cooling: the green leaves are spread thinly to room temperature in time, and the stems and leaves are completely wilted;

[0041] (5) The first molding: adopt a fully automatic intelligent flat tea frying machine, the parameters are 220°C, light pressure (equipment display pressure 1), 15s;

[0042] (6) The second molding: using a fully automatic intelligent flat tea frying machine, the parameters are 220 ° C, medium pressure (equipment display pressure 8), 18s;

[0043] (7)...

Embodiment 2

[0048] (1) Fresh leaves: picking young shoots and the first two spring mulberry leaves as raw materials;

[0049] (2) Spreading: spread the spring mulberry leaves thinly at room temperature until the water content is 63%-66%, and the leaf thickness is 2-3cm. During the cooling process, the fresh leaves should be avoided, and the spreading time is 14 hours;

[0050] (3) Finishing: use a drum fixing machine, the fixing temperature is 380°C to 430°C, and the water content of the leaves is 40% to 43%;

[0051] (4) Cooling: the green leaves are spread thinly to room temperature in time, and the stems and leaves are completely wilted;

[0052](5) The first molding: adopt a fully automatic intelligent flat tea frying machine, the parameters are 230°C, light pressure (the device displays pressure 1), 15s;

[0053] (6) The second molding: using a fully automatic intelligent flat tea frying machine, the parameters are 230 ° C, medium pressure (equipment display pressure 9), 18s;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com