Ultra-thick DLC coating

A coating and ultra-thick technology, which is applied in the fields of ultra-thick DLC coating and its preparation, DLC coating and its preparation, and vacuum PVD coating, can solve problems such as the inability to achieve the ideal thickness of DLC coating, and achieve the goal of suppressing grains. The effects of growth, excellent wear resistance, and convenience for large-scale mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

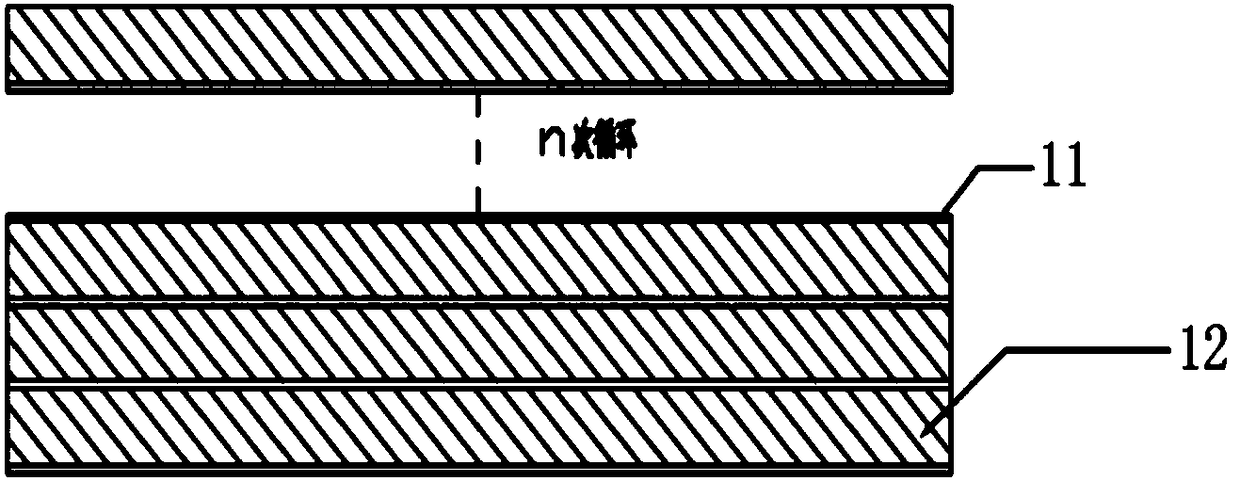

Embodiment 1

[0028] see figure 1 , the ultra-thick DLC coating in Embodiment 1 includes a soft layer 11 directly formed on the surface of the base material, and a hard layer 12 directly formed on the soft layer, and the soft layer 11 and the hard layer 12 are formed alternately on the surface of the base material. The DLC coating formed by multi-period deposition of a double-layer modulation structure consisting of a soft layer and a hard layer has a thickness of 23 μm, a hardness of 30-40 GPa, a friction coefficient of 0.06-0.10, and a modulation period of 0.15-0.90 μm. The internal stress can be controlled below 1.5Gpa, and the bonding force with the surface of the base material is 81N. In this modulated structure, the soft layer 11 is CrN with a thickness of 0.05-0.10μm, and the hard layer 12 is diamond-like carbon with a thickness of 0.10-0.80μm. . see figure 2 , it can be observed that the interface of the modulated structure of the ultra-thick DLC coating is flat and dense, and t...

Embodiment 2

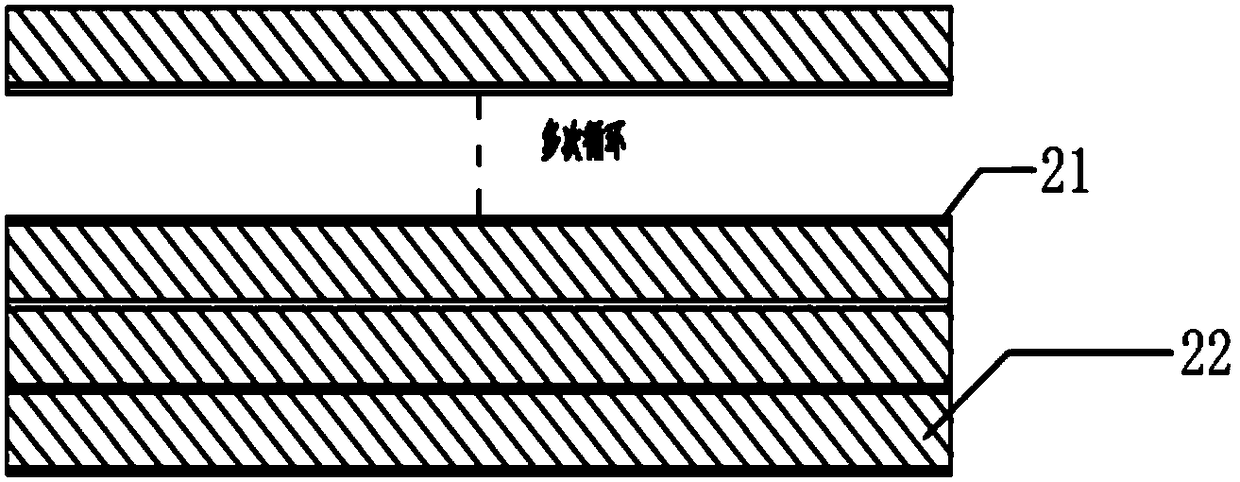

[0040] see image 3 , the ultra-thick DLC coating in Example 2 includes soft layers 21 directly formed on the surface of the base material, and hard layers 22 directly formed on the soft layer, and the soft layers 21 and hard layers 22 are alternately formed on the base material surface. The DLC coating formed by multi-period deposition of a double-layer modulation structure consisting of a soft layer and a hard layer has a thickness of 16 μm, a hardness of 26-36 GPa, a friction coefficient of 0.06-0.10, and a modulation period of 1.50-2.80 μm. The internal stress is only 3.7GPa, and the bonding force with the surface of the base material is 76N. In this modulated structure, the soft layer 21 is CrN with a thickness of 0.50-0.80 μm, and the hard layer 22 is diamond-like carbon with a thickness of 1.00-2.00 μm. . see Figure 4 , it can be observed that the interface of the modulated structure of the ultra-thick DLC coating is flat and dense, and the brightness of each layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com