Retrogression treatment process of 6000-series aluminum alloy thin plate for automobile

A treatment process and aluminum alloy technology, which is applied in the field of regression treatment process, can solve the problems of deterioration of hardening of baking paint, reduction of hardness of alloy plate, increase of strength, etc., and achieve stable performance, energy saving and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

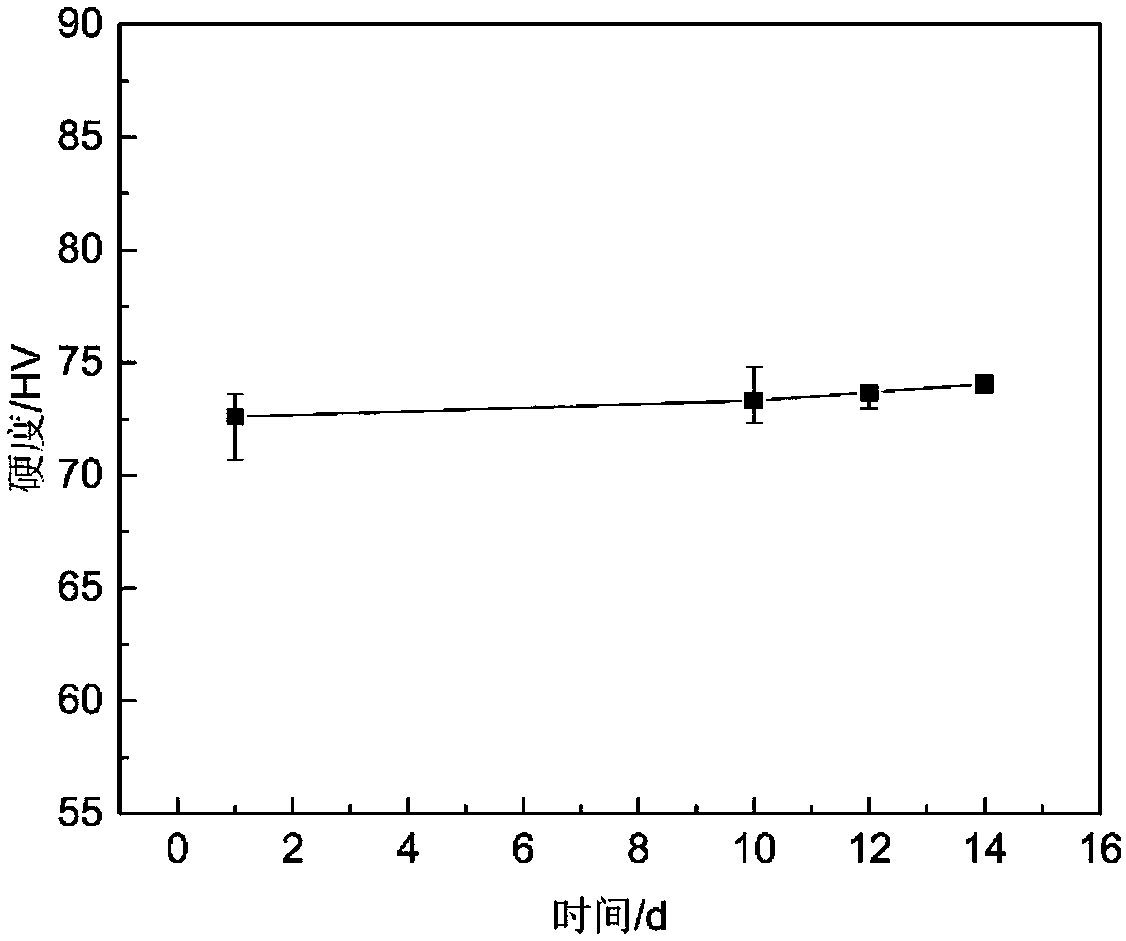

[0032] Cold-rolled 1mm-thick 6016 aluminum alloy sheet for automobile body, after solid solution heat preservation at 560℃×20min in a high-temperature hot air circulation furnace, air-cooled to room temperature, and parked at room temperature for more than 10 months (T4 state). Regression treatment was carried out in a medium-temperature hot air circulation furnace. The regression treatment system was 225°C×5min. After water quenching to room temperature, the hardness test was carried out within 1 day. Subsequently, hardness tests were carried out at 10 days, 12 days and 14 days, respectively. After the regression treatment, the sample that stayed at room temperature for 10 days was selected for simulated baking. The simulated coating baking is carried out in a low-temperature hot air circulation furnace, the process system is 185 ° C × 20min, and the hardness test is carried out after the baking paint treatment.

Embodiment 2

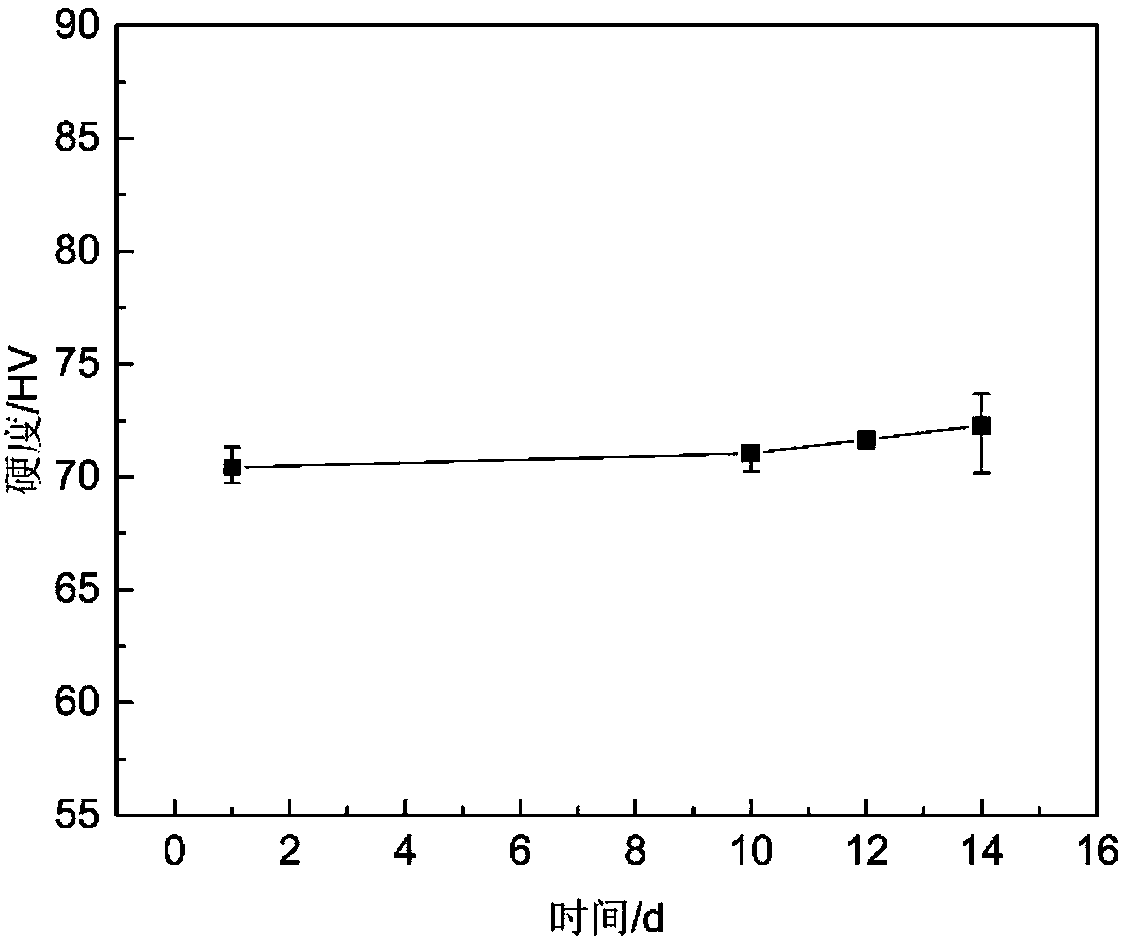

[0034]Cold-rolled 1mm-thick 6016 aluminum alloy sheet for automobile body, after solid solution heat preservation at 560℃×20min in a high-temperature hot air circulation furnace, air-cooled to room temperature, and parked at room temperature for more than 10 months (T4 state). Regression treatment was carried out in a medium-temperature hot air circulating furnace. The regression treatment system was 250°C×2min. After water quenching to room temperature, the hardness test was carried out within 1 day. Subsequently, hardness tests were carried out at 10 days, 12 days and 14 days, respectively. After the regression treatment, the sample that stayed at room temperature for 10 days was selected for simulated baking. The simulated coating baking is carried out in a low-temperature hot air circulation furnace, the process system is 185 ° C × 20min, and the hardness test is carried out after the baking paint treatment.

Embodiment 3

[0036] Cold-rolled 1mm-thick 6016 aluminum alloy sheet for automobile body, after solid solution heat preservation at 560℃×20min in a high-temperature hot air circulation furnace, air-cooled to room temperature, and parked at room temperature for more than 10 months (T4 state). Regression treatment was carried out in a medium-temperature hot air circulation furnace. The regression treatment system was 300°C×15min. After water quenching to room temperature, the hardness test was carried out within 1 day. Subsequently, hardness tests were carried out at 10 days, 12 days and 14 days, respectively. After the regression treatment, the sample that stayed at room temperature for 10 days was selected for simulated baking. The simulated coating baking is carried out in a low-temperature hot air circulation furnace, the process system is 185 ° C × 20min, and the hardness test is carried out after the baking paint treatment.

[0037] Table 1 shows the hardness values tested within one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com