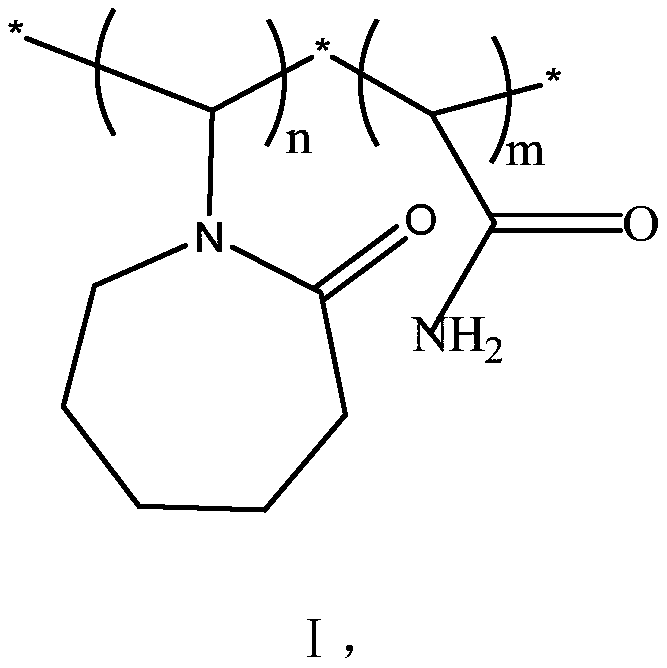

A kind of vinyl amide block copolymer hydrate kinetics inhibitor and its preparation method and application

A kinetic inhibitor, vinyl amide technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of restricting large-scale production and application, the inhibitory effect is not particularly good, and the molecular weight distribution of the product is wide. Achieve controllable synthesis process, excellent inhibitory effect, and narrow molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

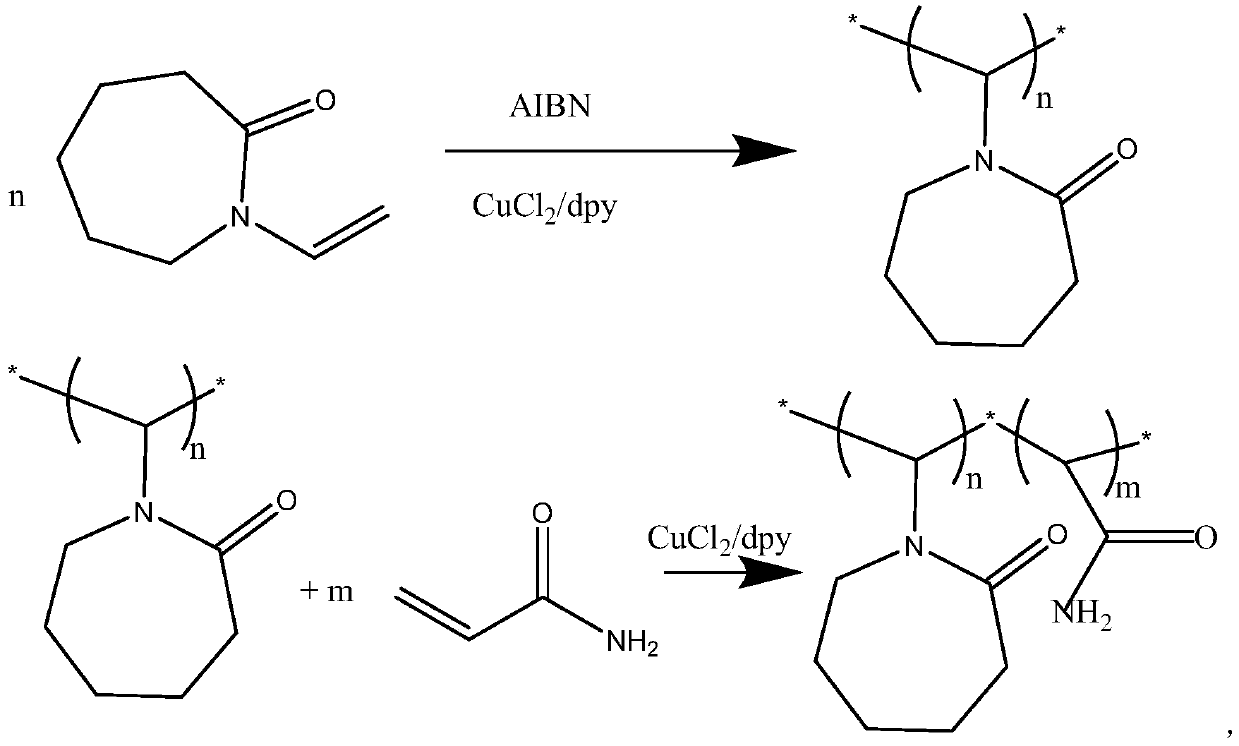

Method used

Image

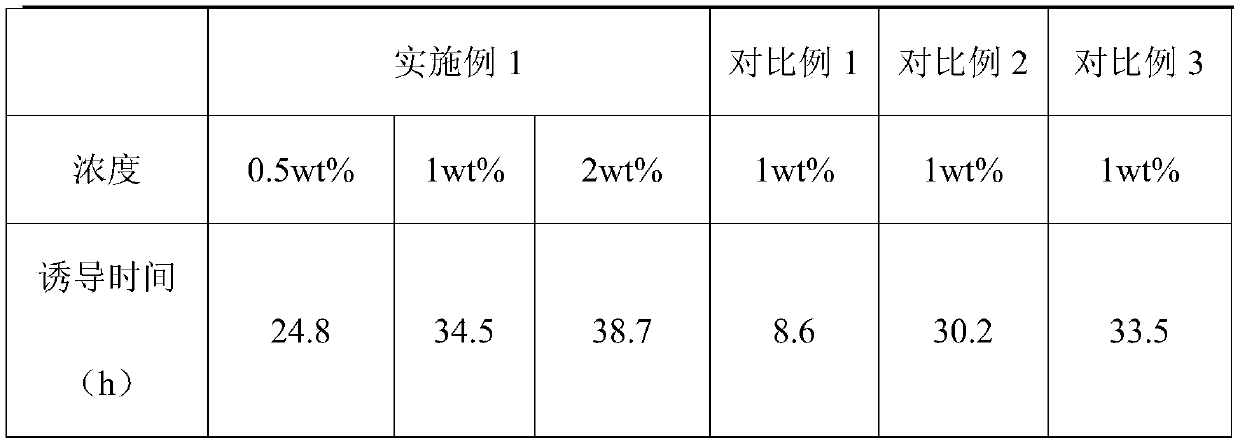

Examples

Embodiment 1

[0033] Take 0.386g of anhydrous copper chloride, 0.898g of 2,2'-bipyridine, and 20g of vinylcaprolactam into a three-necked flask, and then connect the three ports of the flask with a thermometer, a condenser tube, and a rubber hole plug, and the upper end of the condenser tube is connected to the gas path . After evacuating, nitrogen gas is used to preliminarily remove the air in the pipeline. Weigh 0.236g of azobisisobutyronitrile and 90mL of dimethylformamide, dissolve the azobisisobutyronitrile in dimethylformamide, inject the flask from the hole of the rubber stopper with a syringe, and seal it. Then evacuate and circulate nitrogen for three times to ensure anaerobic operating conditions. Turn on the condensed water circulation, turn on the magnetic stirring at 300rpm, turn on the oil bath and raise the temperature to 80°C. After reacting for 40 hours, 10.214 g of acrylamide was weighed and added to the flask under nitrogen protection. Continue to react for 40 hours, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com