Airflow generating device, graphene dispersion liquid and preparation method thereof

A graphene dispersion and production device technology, applied in graphene, chemical instruments and methods, nano-carbon and other directions, can solve the problems of low solid content, low yield, reduced physical properties of graphene, etc., and achieve high solid content and high yield. rate, the effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054]The invention provides an airflow generating device for preparing graphene powder, a graphene dispersion and a preparation method thereof, wherein the graphene powder produced by the airflow generating device is used to prepare the graphene dispersion. Hereinafter, details of the airflow generating device, graphene dispersion and preparation method thereof of the present invention will be described in detail.

[0055]

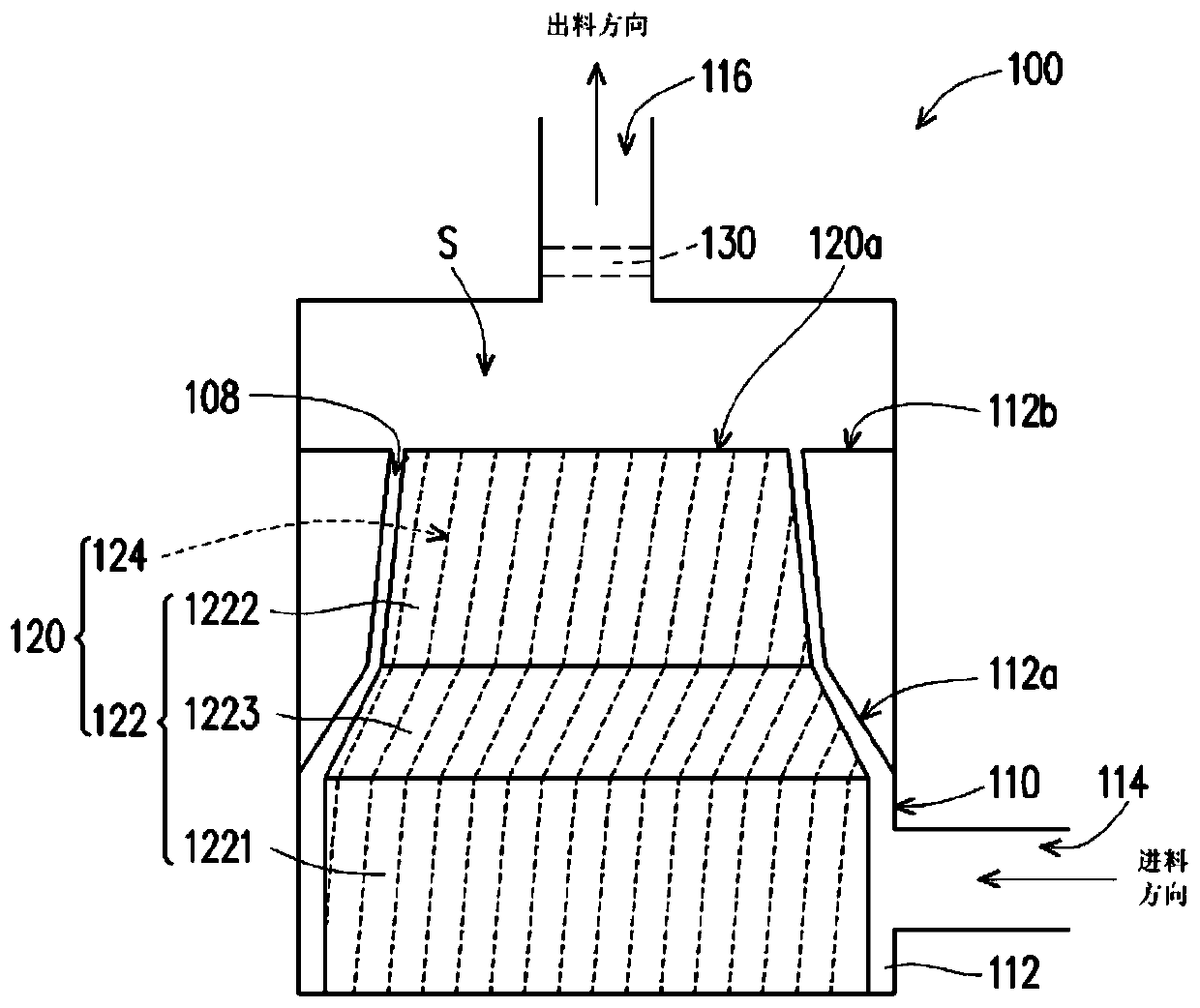

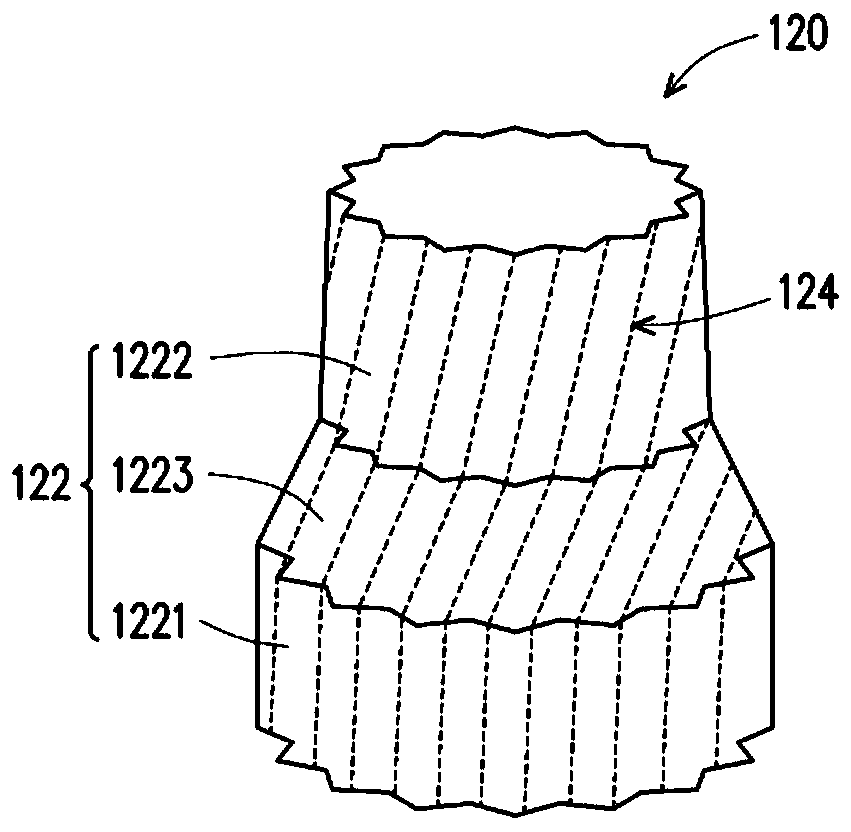

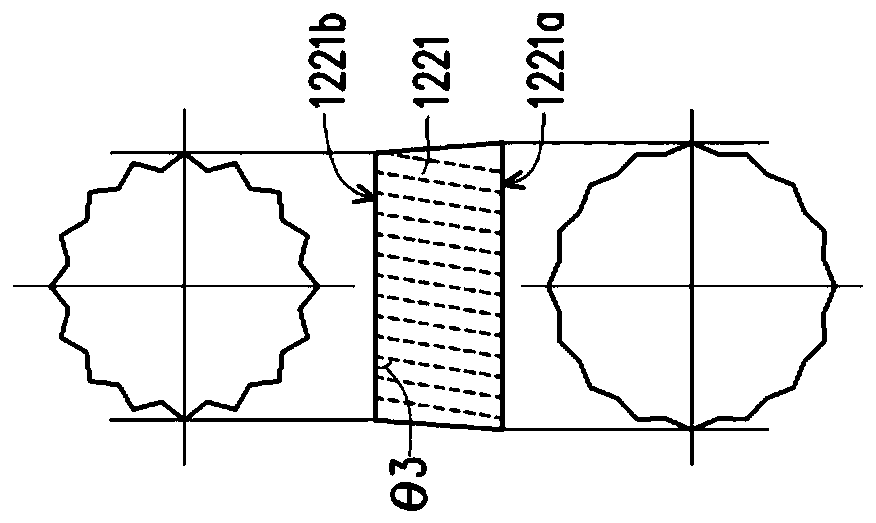

[0056] figure 1 is a cross-sectional view of the airflow generating device, and figure 2 for figure 1 A three-dimensional schematic diagram of a rotating awl. Please also refer to figure 1 and figure 2 , the airflow generating device 100 includes an outer bushing 110 and a rotating awl 120 , wherein the outer bushing 110 has a chamber 112 , an air inlet opening 114 and an air outlet opening 116 . The air inlet opening 114 communicates with the lower side of the chamber 112 and the air outlet opening 116 communicates with the upper side of the cha...

experiment example

[0090] In order to prove that the graphene dispersion of the present invention has a relatively high solid content and suspending property, this experimental example is specially made below.

[0091] It must be noted that since the preparation method of the graphene dispersion has been described in detail above, therefore, the preparation details of the graphene dispersion will be omitted for convenience.

[0092] Preparation of graphene dispersion

[0093] According to the above-mentioned preparation method of the graphene dispersion of the present invention, the graphene dispersions of Examples 1 to 21 were prepared with the composition conditions and process conditions listed in Table 1 below. In Table 1, the mixing ratio (G / S) represents the ratio of graphene / solvent (Graphene / Solvent).

[0094] Table 1

[0095]

[0096] Evaluation 1: Characteristic Evaluation of Graphene Dispersion

[0097] For the graphene dispersion made in example 1 to example 21, measure the ave...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com