Hot isostatic pressure diffusion bonding method of copper chromium zirconium-stainless steel composite plate

A technology of hot isostatic pressure diffusion and connection method, applied in welding equipment, non-electric welding equipment, metal processing equipment and other directions, can solve the problems of low product yield, unstable connection performance, defects in the connection interface, etc. Product yield, stable connection performance, and the effect of reducing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below by means of the accompanying drawings and specific embodiments.

[0024] Various reagents and materials used in the embodiment meet the following requirements respectively:

[0025] Gasoline for parts cleaning complies with GB 17930-2011 / XG1-2012 standard;

[0026] Acetone for parts cleaning complies with GB / T 6026-1998 standard;

[0027] High-purity argon gas (purity ≥ 99.99%) for hot isostatic pressing medium complies with GB / T4842-1995 standard;

[0028] The processed workpieces are copper chromium zirconium and 316L stainless steel plates.

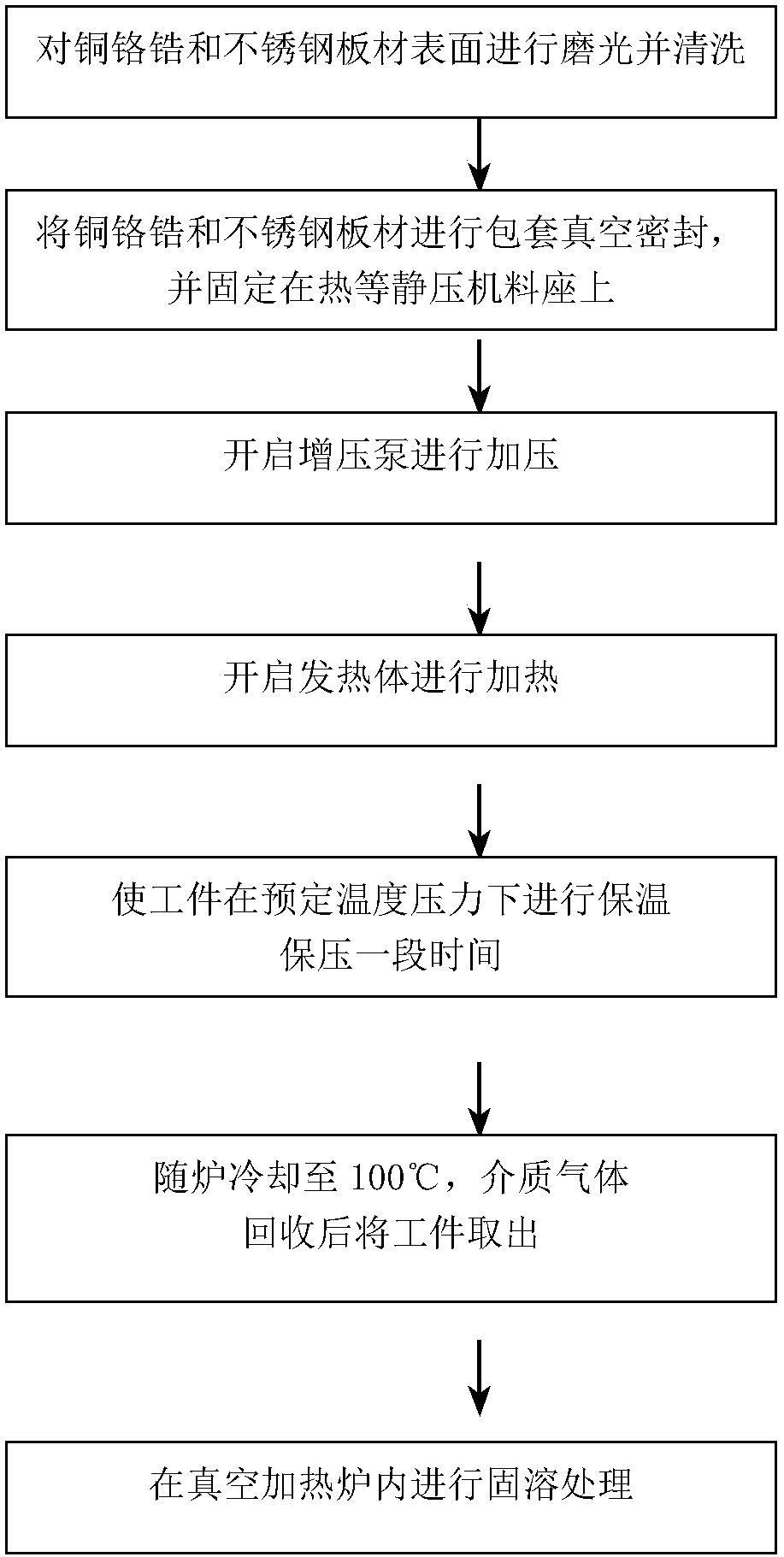

[0029] The specific steps of this method are as follows: figure 1 as shown,

[0030] (1) The connection interface between copper, chromium, zirconium and stainless steel needs to be polished first, and the oil on the surface of the workpiece should be removed with gasoline, then cleaned with acetone organic solvent, and dried with argon;

[0031] The purpose of this is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com