Cement ball grinding mill for building technical services

A technical service, ball mill technology, applied in the technical service field, can solve the problems of inability to grind cement and shorten the service life of the grinder, and achieve the effect of improving the cooling effect, high safety performance, and enhancing the safety factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

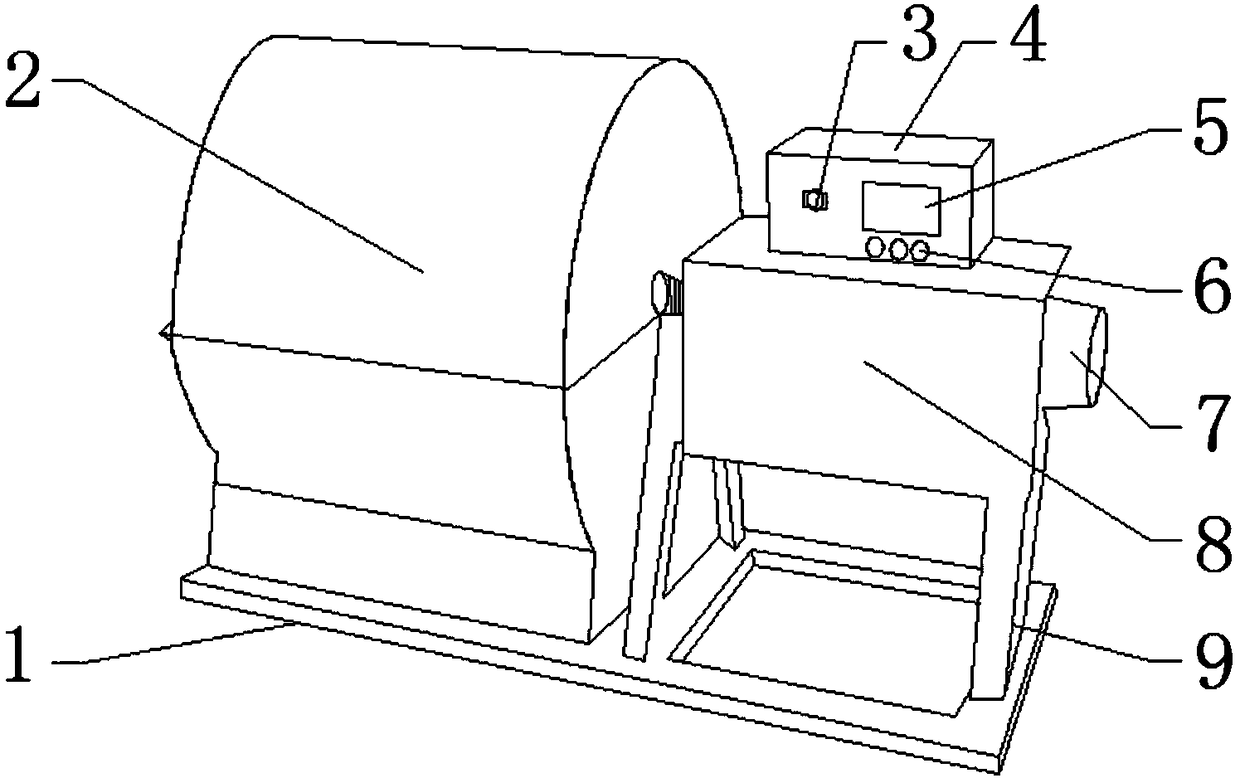

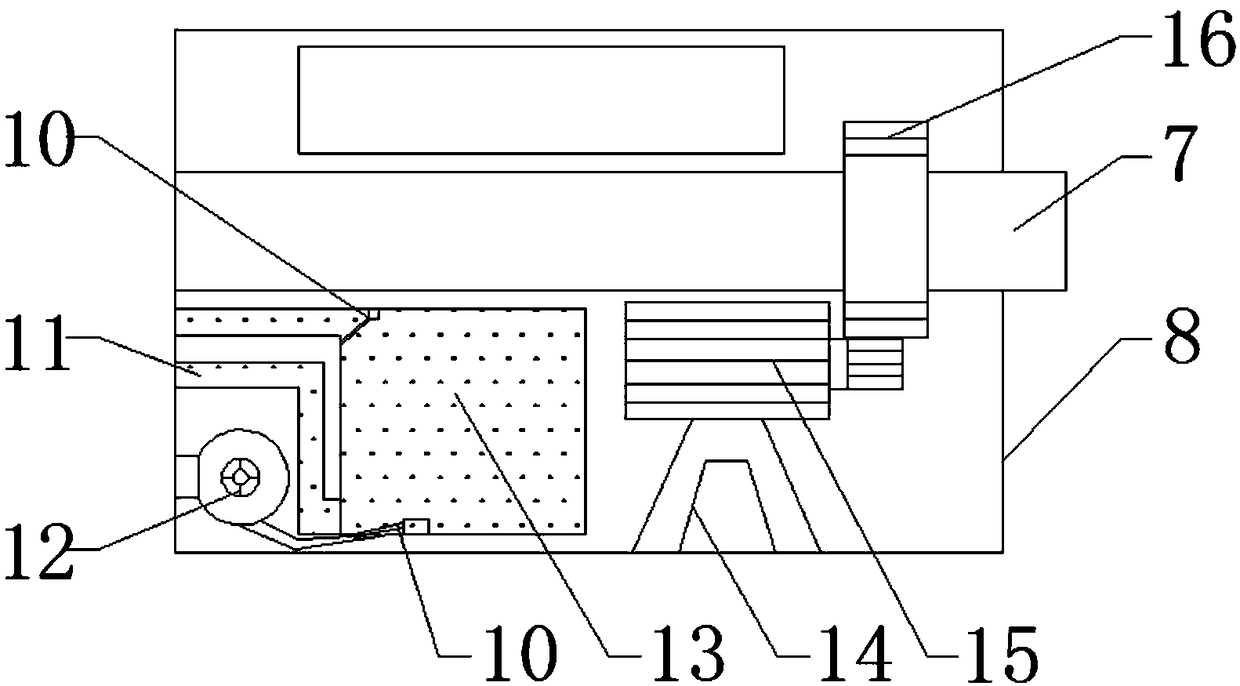

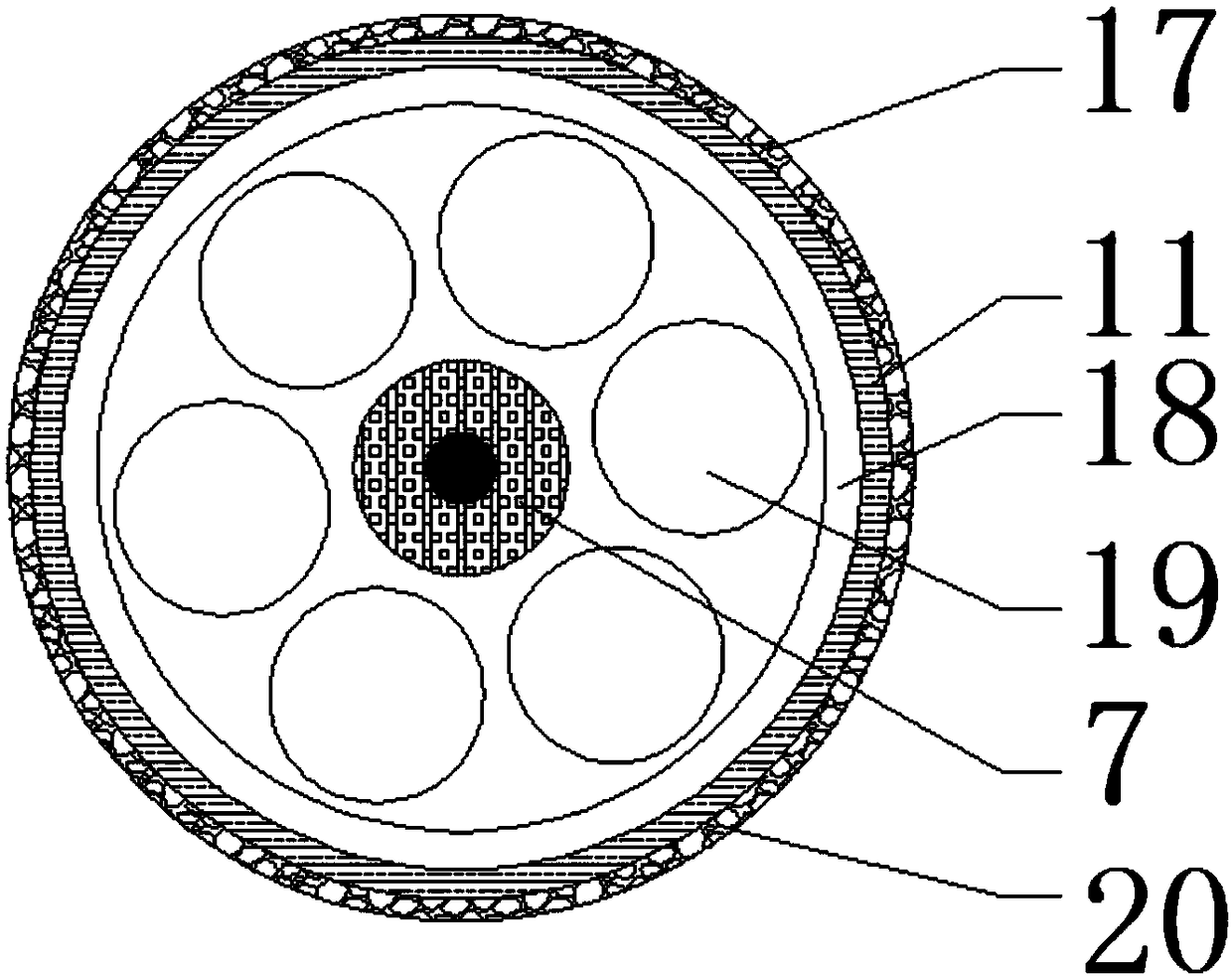

[0017] see Figure 1-Figure 3 , the present invention provides a technical solution: a cement ball mill for construction technical service, comprising a ball mill main body 2, an electric control box 4 is installed on the ball mill main body 2, and an emergency stop button 3 and an LED display are installed on the front surface of the electric control box 4 5 and the control button 6, the emergency stop button 3 is located on the left side of the LED display 5, the LED display 5 is located above the control button 6, the ball mill base 1 is installed on the ball mill main body 2, and the power control box 8 is installed on the ball mill main body 2, A water storage tank 13 is installed inside the power control box 8, and a water circulation pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com