High temperature chlorination shaft furnace

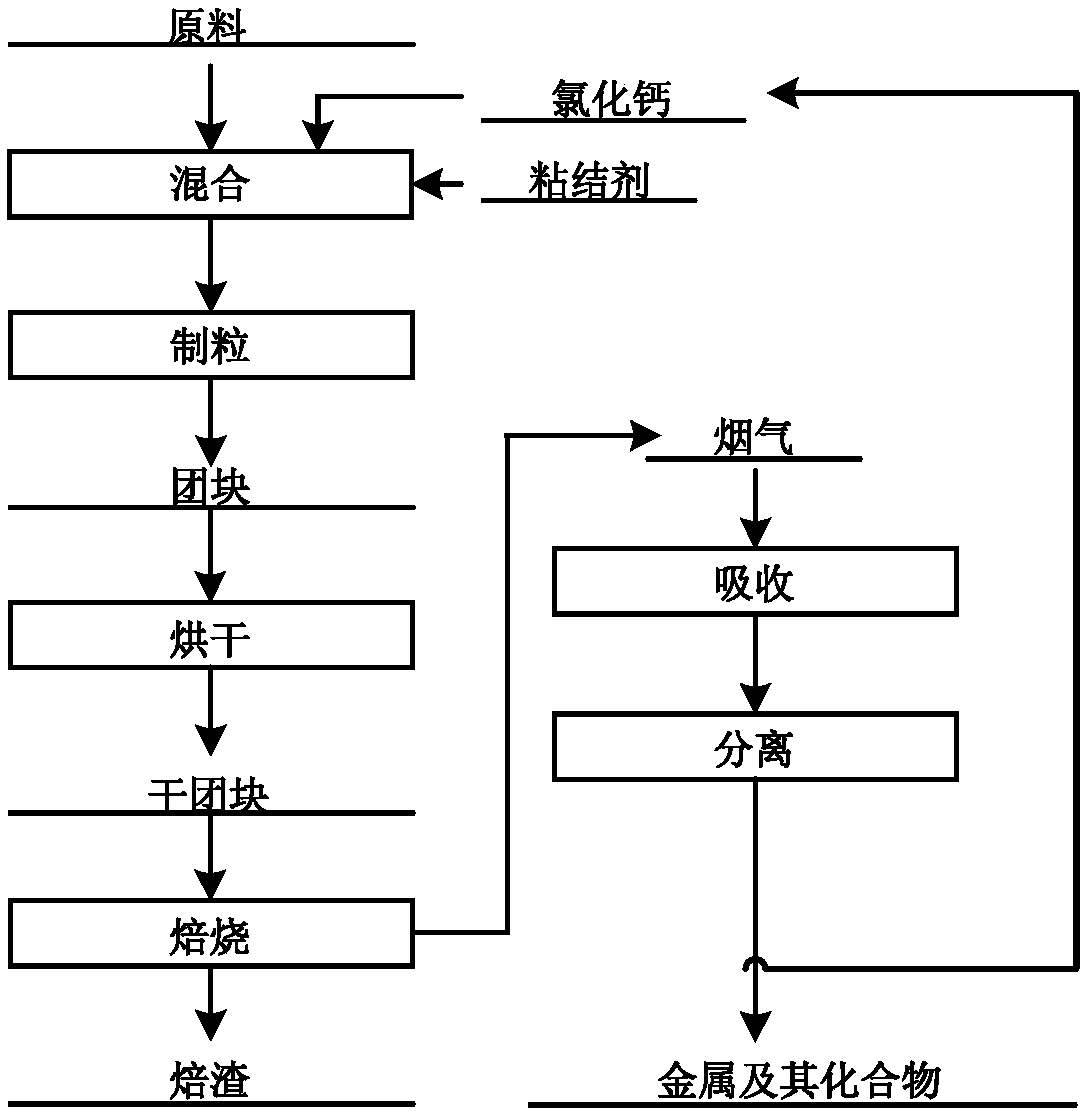

A high-temperature chlorination and shaft furnace technology, applied in the field of high-temperature chlorination process production equipment, can solve the problems that the strength of pellets cannot meet the requirements of ironmaking and uniform roasting, etc., and achieve strong flame penetration, uniform product quality, The effect of low investment in land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

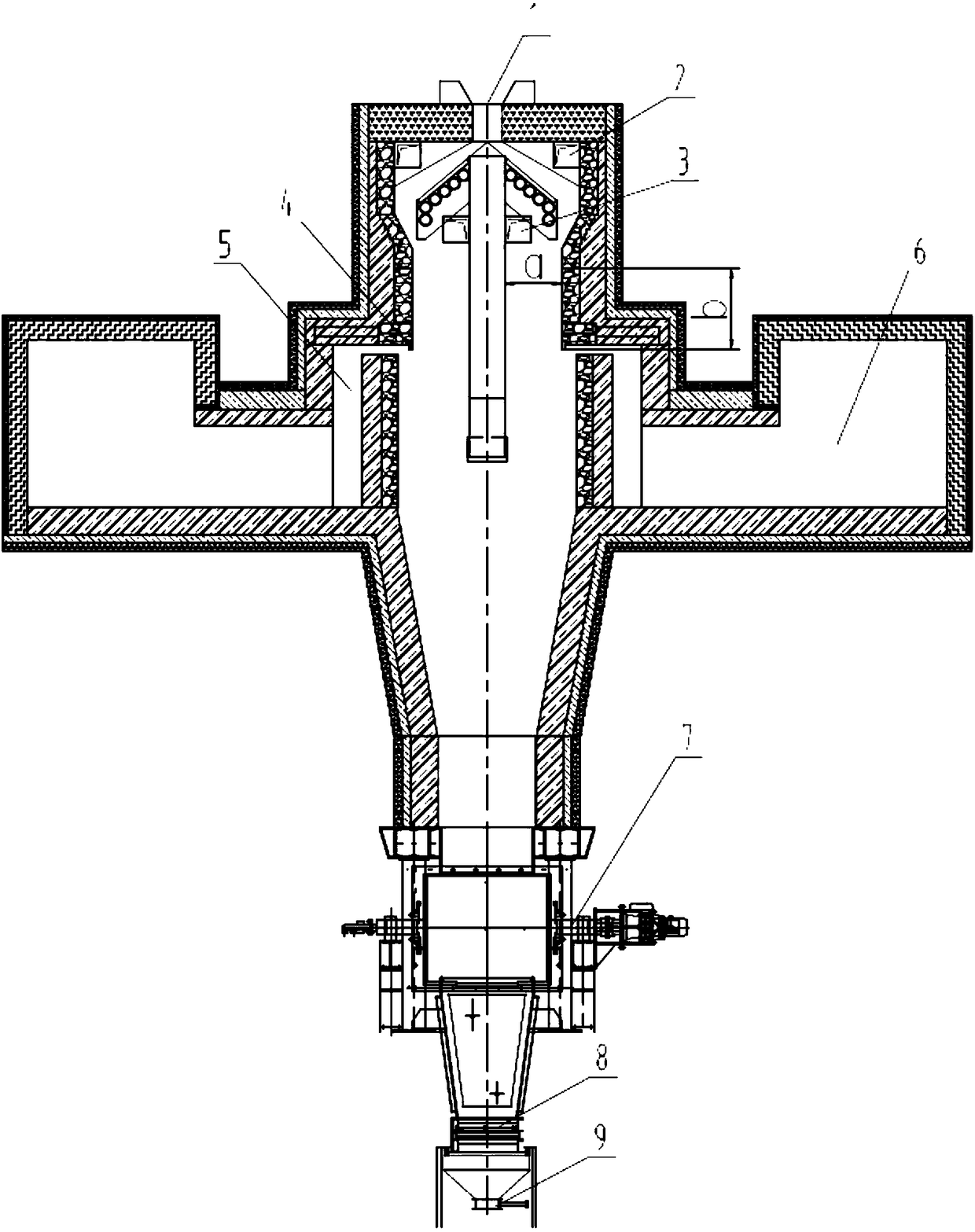

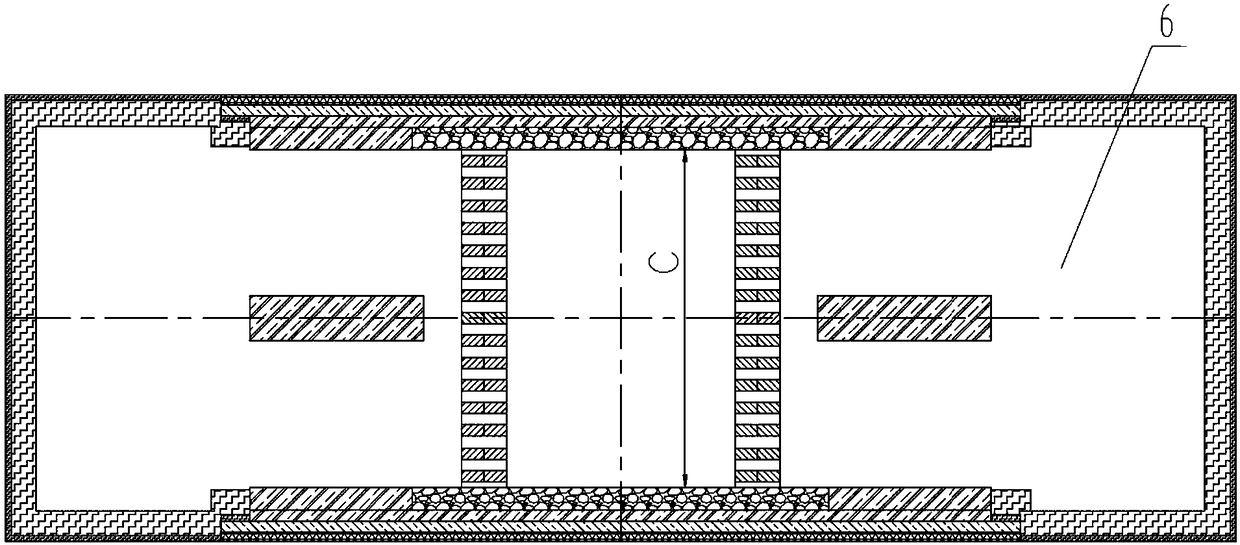

[0017] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0018] As shown in Figure 1, the shaft furnace of the present invention is installed on a reinforced concrete platform. There are four layers of platforms. The bottom layer is for installing discharge equipment and combustion-supporting fans, etc.; Fans, hot air induced draft fans, combustion air preheaters, electric control cabinets and other equipment are the main equipment installation and stress-bearing floors; the third floor is equipped with combustion chambers, combustion systems, operating rooms and other equipment, which is the main operation floor; the fourth floor is installed Feeding machinery, chlorinated gas extraction device, etc. are the feeding layer; lifting equipment is installed under the top layer for installation and maintenance. The installation sequence is to install the disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com