A double ceramic layer thermal barrier coating system and its composite preparation process

A thermal barrier coating and preparation process technology, applied in metal material coating process, coating, melt spraying and other directions, can solve the problems of low thermal expansion coefficient of LCO, cracking and peeling of ceramic layer and bonding layer, etc. Good thermal cycle damage performance, improve anti-oxidation performance and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

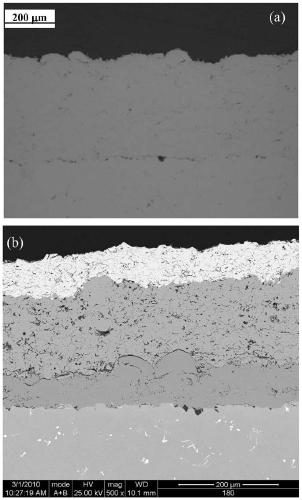

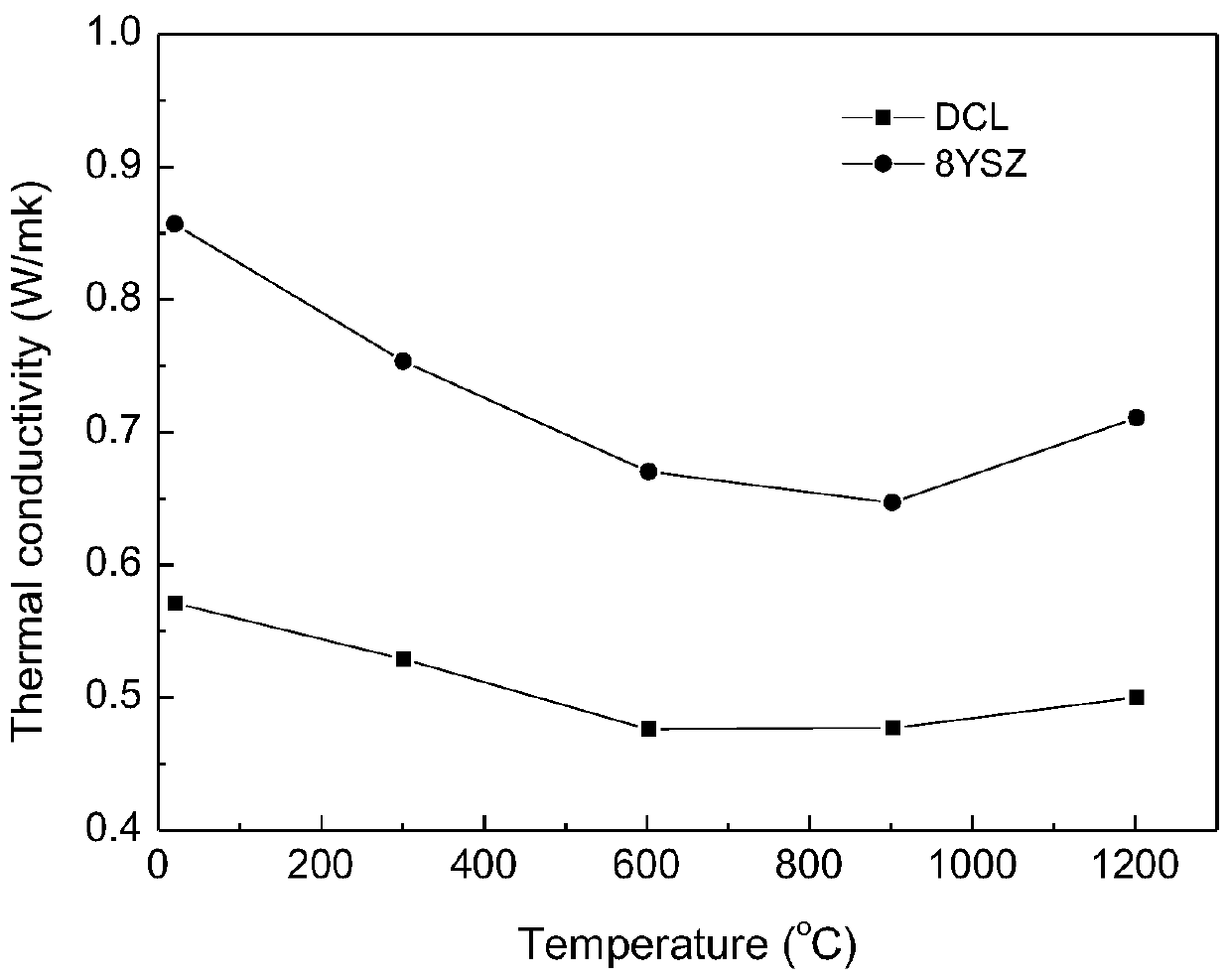

[0047] A dual ceramic layer thermal barrier coating system comprising a bond coat, a YSZ coating and a lanthanum cerate coating on a superalloy substrate;

[0048] Described bonding layer is MCrAlY bonding layer;

[0049] The YSZ coating is a yttria stabilized zirconia coating, namely ZrO 2 +8wt.%Y 2 o 3 ; Among them, the other ingredients and mass percentage contained are SiO 2 1.5%, Fe 2 o 3 0.9%, CaO 1.2%, MgO 1.0%, HfO 2 2.8%;

[0050] The MCrAlY bonding layer is a NiCrAlY bonding layer, the mass percent of each metal element is 25% for Cr, 10% for Al, 0.8% for Y, and the balance is Ni.

[0051] The thickness of the bonding layer is 85 μm, the thickness of the YSZ coating is 120 μm, and the thickness of the lanthanum cerate coating is 80 μm.

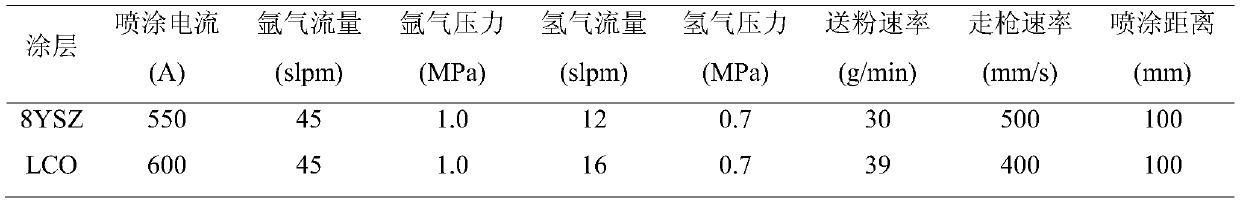

[0052] A composite preparation process of a double-ceramic layer thermal barrier coating system. According to the results of process optimization tests, the process parameters of each layer of the thermal barrier coating syst...

Embodiment 2

[0069] A dual ceramic layer thermal barrier coating system comprising a bond coat, a YSZ coating and a lanthanum cerate coating on a superalloy substrate;

[0070] Described bonding layer is MCrAlY bonding layer;

[0071] The YSZ coating is a yttria stabilized zirconia coating, namely ZrO 2 +7wt.%Y 2 o 3 ; Among them, the other ingredients and mass percentage contained are SiO 2 1.2%, Fe 2 o 3 0.7%, CaO 1.3%, MgO 1.2%, HfO 2 2.4%;

[0072] When the MCrAlY bonding layer is a NiCoCrAlTaY bonding layer, the mass percent of each metal element is 30% for Co, 25% for Cr, 12% for Al, 7.0% for Ta, 0.4% for Y, and the balance For you.

[0073] The thickness of the bonding layer is 200 μm, the thickness of the YSZ coating is 150 μm, and the thickness of the lanthanum cerate coating is 120 μm.

[0074] A composite preparation process of a double ceramic layer thermal barrier coating system is carried out according to the following steps:

[0075] Step 1, superalloy substrate pr...

Embodiment 3

[0089] A dual ceramic layer thermal barrier coating system comprising a bond coat, a YSZ coating and a lanthanum cerate coating on a superalloy substrate;

[0090] Described bonding layer is MCrAlY bonding layer;

[0091] The YSZ coating is a yttria stabilized zirconia coating, namely ZrO 2 +9wt.%Y 2 o 3 ; Among them, the other ingredients and mass percentage contained are SiO 2 1.6%, Fe 2 o 3 0.9%, CaO 1.0%, MgO 1.4%, HfO 2 2.9%;

[0092] When the MCrAlY bonding layer is a NiCrAlY bonding layer, the mass percent of each metal element is 20% for Cr, 14% for Al, 0.4% for Y, and the balance is Ni.

[0093] The thickness of the bonding layer is 200 μm, the thickness of the YSZ coating is 100 μm, and the thickness of the lanthanum cerate coating is 120 μm.

[0094] A composite preparation process of a double ceramic layer thermal barrier coating system is carried out according to the following steps:

[0095] Step 1, superalloy substrate pretreatment

[0096] Carry out t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com