Method for preparing H-SSZ-13 molecular sieve

A molecular sieve and template technology, which is applied in the field of preparation of H-SSZ-13 molecular sieve, can solve the problem of no substantial progress in the cost of the template, and achieve the effects of shortening the crystallization time, improving the utilization rate, and reducing the use of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

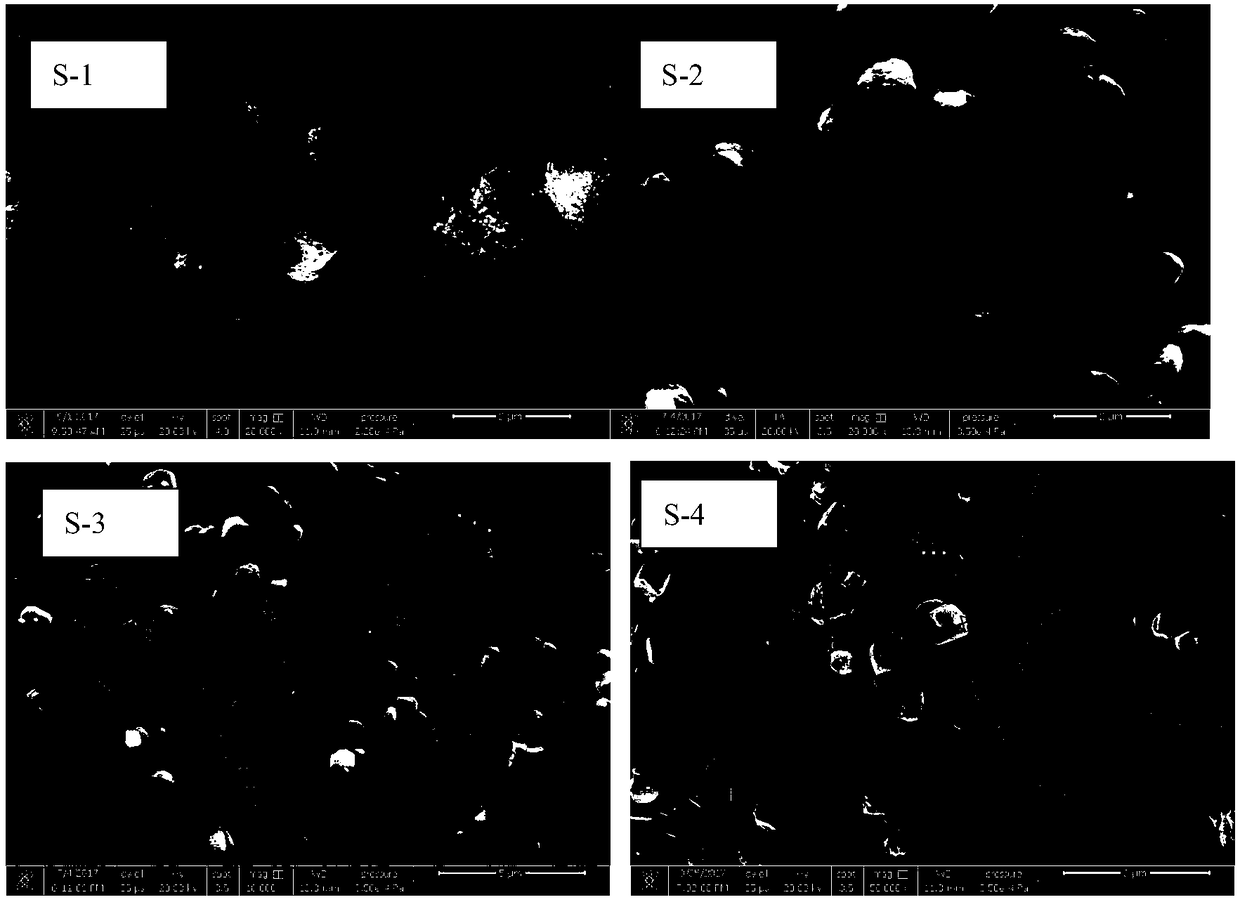

Image

Examples

Embodiment 1

[0031] The preparation method of H-SSZ-13 molecular sieve of the present invention is characterized in that comprising the following steps:

[0032] Add silica sol, N,N,N-trimethyladamantyl ammonium hydroxide and pseudo-boehmite into deionized water in sequence. The proportion of each component is SiO 2 :Al 2 o 3 :R:H 2 O=1:0.2:0.15:15. After mixing and stirring evenly, transfer to the reactor, and crystallize at 100° C. for 12 hours to obtain the directing agent slurry (G-1).

[0033] Add ethanol, triethylamine, N,N,N-trimethyladamantyl ammonium hydroxide, silica sol, and pseudoboehmite in sequence in deionized water, and stir well to form a uniform gel. The molar ratio of each component substance in the gel is SiO 2 :Al 2 o 3 :R:R1:C:H 2 O=1:0.02:0.03:1.5:0.05:14. A 4% directing agent solution (G-1) on a dry basis of the slurry was then added. After fully mixed, put it into the reaction kettle, and crystallize at 160°C for 72 hours. After the crystallization, the ...

Embodiment 2

[0035] The preparation method of H-SSZ-13 molecular sieve of the present invention is characterized in that comprising the following steps:

[0036] Add silica gel, N,N,N-trimethyladamantyl ammonium hydroxide, and pseudo-boehmite to deionized water in sequence. The proportion of each component is SiO 2 :Al 2 o 3 :R:H 2 O=1:0.25:0.18:16. After mixing and stirring evenly, it was transferred to a reaction kettle, and crystallized at 110° C. for 12 hours to obtain a directing agent slurry (G-2).

[0037] Add acetamide, diethylamine, N,N,N-trimethyladamantyl ammonium hydroxide, silica gel, and pseudoboehmite in sequence in deionized water, and stir well to form a uniform gel. The molar ratio of each component substance in the gel is SiO 2 :Al 2 o 3 :R:R1:C:H 2 O=1:0.0333:0.04:1.4:0.04:14. A 6% directing agent solution (G-2) on a dry basis of the slurry was then added. Put it into the reaction kettle after mixing well, and crystallize at 170°C for 60 hours. After the crys...

Embodiment 3

[0039] The preparation method of H-SSZ-13 molecular sieve of the present invention is characterized in that comprising the following steps:

[0040]Add silica sol, N,N,N-trimethyladamantyl ammonium hydroxide, and aluminum sulfate to deionized water in sequence. The proportion of each component is SiO 2 :Al 2 o 3 :R:H 2 O=1:0.2:0.14:16. After mixing and stirring evenly, transfer to the reaction kettle, and crystallize at 100° C. for 12 hours to obtain the directing agent slurry (G-3).

[0041] Add ethylene glycol, triethylamine, N,N,N-trimethyladamantyl ammonium hydroxide, silica sol, and aluminum sulfate in deionized water in sequence, and stir well to form a uniform gel. The molar ratio of each component substance in the gel is SiO 2 :Al 2 o 3 :R:R1:C:H 2 O=1:0.05:0.04:1.8:0.06:14. An 8% directing agent solution (G-3) on a dry basis of the slurry was then added. Put it into the reaction kettle after mixing well, and crystallize at 160°C for 60 hours. After the crys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com