Hot-pressing color-changing stratified structure, hot-pressing color-changing synthetic leather and preparation method thereof

A color-changing layer and synthetic leather technology, which is applied in textiles and papermaking, can solve the problems of single color-changing effect and high cost of color-changing synthetic leather, and achieve the effect of low cost and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Further, this embodiment also provides a method for preparing hot-pressed discoloration synthetic leather, comprising the following steps:

[0043] Foaming the first slurry to make a coating, drying at 70°C to 120°C to obtain a foamed layer;

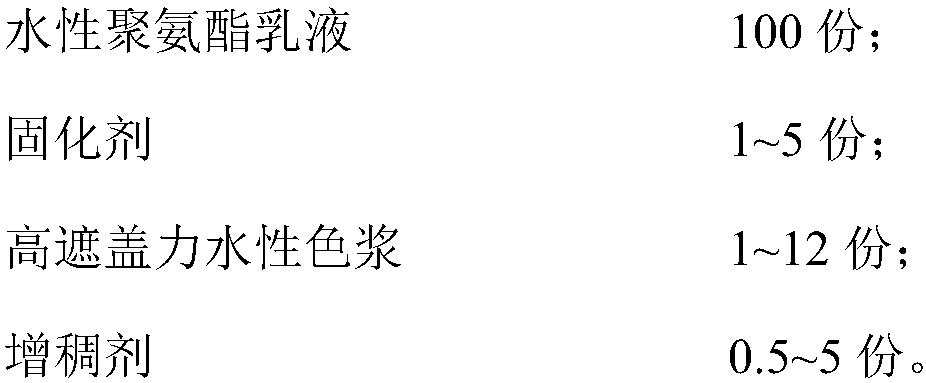

[0044] Make a base color layer on the foam layer;

[0045] Make an adhesive layer on the base color layer;

[0046] The base cloth and the adhesive layer are laminated to obtain undiscolored synthetic leather;

[0047] Carrying out hot pressing to the uncolored synthetic leather to obtain hot pressed discolored synthetic leather.

[0048] In the embodiment that the heat-pressing color-changing synthetic leather includes a transparent protective layer, the transparent protective layer can be made on the release paper earlier, and then the foaming layer can be made on the transparent protective layer, or the foaming layer can be made on the release paper earlier. Layer, after the bonding of the base fabric and the adhesive layer ...

Embodiment 1

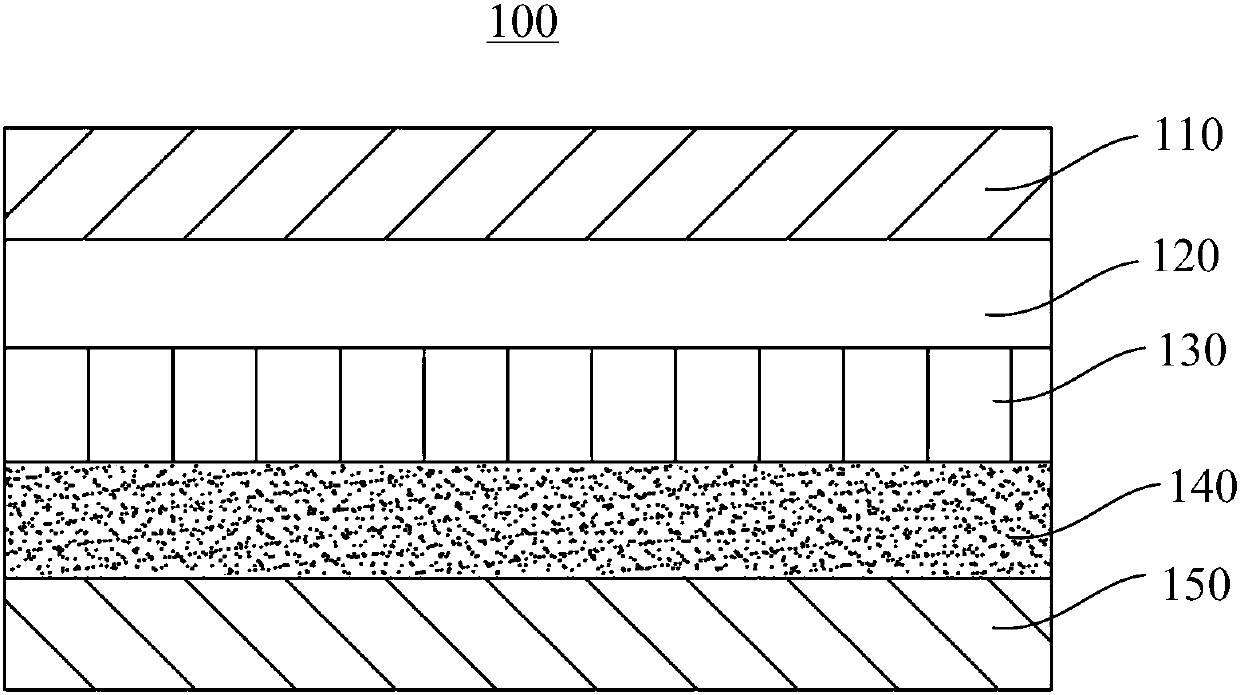

[0069] This embodiment provides a hot-press color-changing water-based synthetic leather. The base color of the synthetic leather is full-color, and the hot-pressed parts become black. The synthetic leather comprises a transparent protective layer, a foam layer, a ground color layer, an adhesive layer and a polyester cloth which are sequentially stacked, and the preparation steps are as follows:

[0070] (1) Scrape-coat a layer of the third slurry with high transparency and good wear resistance on the release paper, the thickness of the coating is 0.02mm, and dry at 70°C to obtain a transparent protective layer.

[0071] The viscosity of the third slurry is 400mpa.s. The third slurry is made of the following raw material components in parts by weight: 100 parts of DLC-F type water-based polyurethane emulsion, 1 part of N3390 type isocyanate curing agent, 2 parts of D816 type wear agent, 0.2 part of 3236 type hand feel agent, ALA type Thickener 0.5 part.

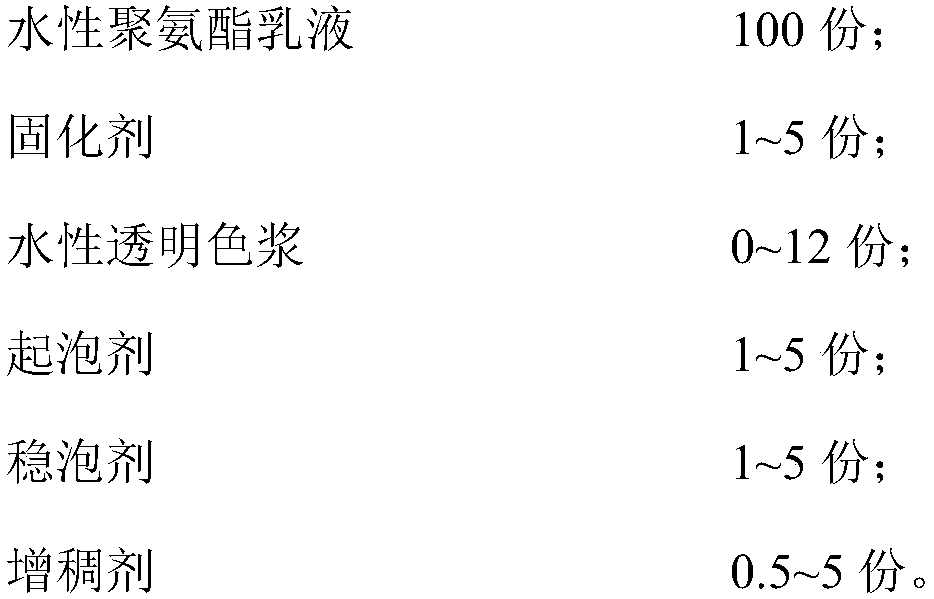

[0072] (2) Foaming ...

Embodiment 2

[0081] This embodiment provides a water-based synthetic leather that changes color by hot pressing. The synthetic leather comprises a transparent protective layer, a foam layer, a ground color layer, an adhesive layer and a cotton cloth which are sequentially stacked, and the preparation steps are as follows:

[0082] (1) Squeeze-coat a layer of the third slurry with high transparency and good wear resistance on the release paper, the thickness of the coating is 0.2mm, and dry at 120°C to obtain a transparent protective layer.

[0083] The viscosity of the third slurry is 1500mpa.s. The third slurry is made of the following raw material components in parts by weight: 100 parts of DLC-F type water-based polyurethane emulsion, 5 parts of N3390 type isocyanate curing agent, 0.2 part of D816 type wear agent, 2 parts of 3236 type hand feeling agent, ALA type Thickener 5 parts.

[0084] (2) Foaming the first slurry, foaming with mechanical agitation and foaming, the foaming densit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com