Method of using red algae extracting solution to directly prepare carrageenan fiber

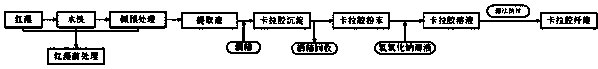

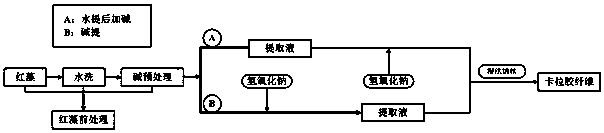

A technology for extracting liquid and carrageenan, which is applied in the chemical characteristics of fibers, wet spinning, rayon manufacturing, etc., can solve the problems of complex process and high consumption, and achieve the effect of simple process, low energy consumption and lower product price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Take 100g of cleaned fresh carrageenan, cut it into small pieces of about 1cm, add 1000ml of 6% NaOH solution, heat in a water bath and adjust the temperature to 70°C for 1h pretreatment. Take out the pretreated red algae, then add 200ml of 8% NaOH solution, heat in a water bath at 95°C for 2 hours, and filter the extracted solution containing impurities with two layers of 200-mesh gauze to obtain the extracted solution. Pour the extract into the spinning kettle, enter the spinneret after defoaming, and use 15% BaCl 2 The solution is used as a coagulation bath, and the carrageenan fiber is prepared by wet spinning. The as-spun fiber is stretched, washed with water, dehydrated with 95% ethanol, and finally the carrageenan fiber is dried in a ventilated place.

Embodiment 2

[0030] Take 70g of cleaned fresh sand vegetables, cut them into pieces, add 1000ml of 6% NaOH solution, heat in a water bath and adjust the temperature to 60°C for 2h pretreatment. Add 210ml of 10% NaOH to the pretreated red algae, heat and extract in a water bath at 90°C for 2.5h, and filter with two layers of 200-mesh gauze to obtain the extract. Pour the extract into the spinning kettle, enter the spinneret after defoaming, use 7% KCl solution as coagulation bath, 7% CaCl 2 The solution is used as a stretching bath, and the carrageenan fiber is prepared by wet spinning. The primary fiber is stretched, washed with water, dehydrated with 95% ethanol, and finally the carrageenan fiber is dried in a ventilated place.

Embodiment 3

[0032] Take 8.5g cleaned dry Eucheuma, cut into pieces, soak in 1000ml of deionized water for 24 hours, take it out and add 1000ml of 10% NaOH solution, heat in a water bath and adjust the temperature to 80°C for 0.5h, wash with water, add 300ml of deionized water , heating and extracting in a water bath at 85°C for 3 hours, adding 2.4g NaOH to the extract while it was hot, stirring evenly, filtering the extract containing impurities with two layers of 200-mesh gauze to obtain the extract. Pour the extract into the spinning kettle, enter the spinneret after defoaming, and use 10% CuCl 2 The solution is used as a coagulation bath, and the carrageenan fiber is prepared by wet spinning. The as-spun fiber is stretched, washed with water, dehydrated with 95% ethanol, and finally the carrageenan fiber is dried in a ventilated place.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com