A method for comprehensive recovery of complex high-silver ore

A silver ore and complex technology, applied in the field of comprehensive recovery of complex high-silver ore, can solve the problems of excessively long process flow, reduced direct yield, long recovery time, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

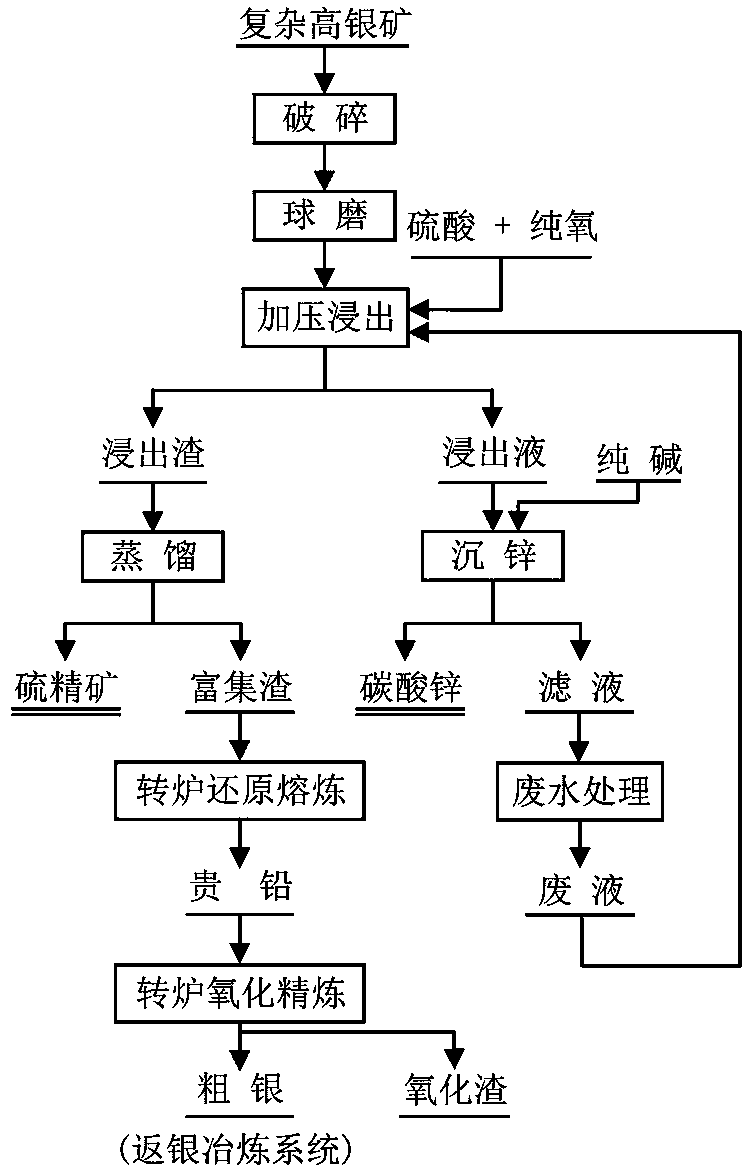

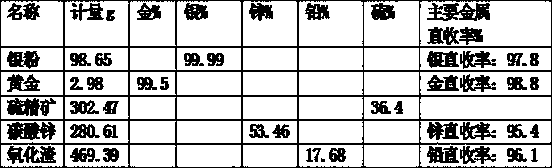

[0019] The process trend is described in detail below in conjunction with specific process implementation modes.

[0020] A kind of technological process of comprehensively recovering complex high silver ore is as follows:

[0021] 1) Pressure leaching conditions: ball milling to a particle size of 100-300 mesh, liquid-solid ratio of 4-8:1, sulfuric acid concentration of 2-5mol / L, temperature of 140-170°C, speed of 400-800r / min, pressure 0.5-2.0 MPa, reaction time 2-5h;

[0022] 2) Distillation conditions: strictly control the temperature at 200-500°C, and the distillation time is 3-8h;

[0023] 3) Converter reduction smelting conditions: the melting temperature is 1100-1200°C; the precipitation time is 2-6h; the furnace time is 18-22h; the slagging temperature is 1100-1200°C;

[0024] 4) Converter oxidation and refining conditions: fume run-off temperature is 900-950°C; oxidation slagging temperature is 1000-1100°C, and the total time is 40-60h; slagging conditions are: mai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com