Method for producing plastic mold steel slab with high flaw detection requirement by using elliptical continuous casting billet

A technology of plastic mold steel and continuous casting slabs, which is applied in the direction of metal rolling, can solve the problems of many harmful elements, large performance differences, and high production costs, and achieve the effects of less harmful elements, high internal density, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

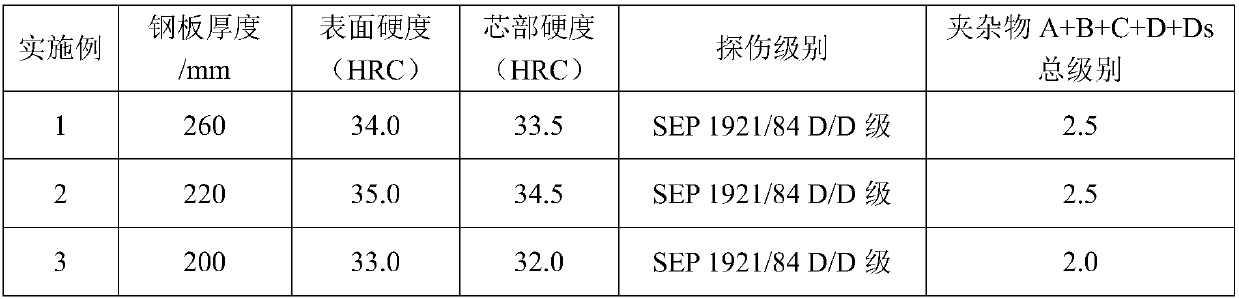

Embodiment 1

[0026] The thickness of the plastic mold steel thick plate suitable for high flaw detection requirements involved in this embodiment is 260mm, and its chemical composition is calculated by mass percentage: C: 0.41%, Si: 0.28%, Mn: 1.60%, P: 0.005%, S : 0.002%, Cr: 2.0%, Mo: 0.28%, and the balance is Fe and unavoidable impurity elements.

[0027] The manufacturing process of the steel plate is as follows:

[0028] Production process: Converter steelmaking → refining → vacuum degassing → ф900*1350mm oval billet continuous casting → slow cooling → heating in soaking furnace → rolling → heat treatment → finishing → inspection → storage.

[0029] The specific operation of the main process is as follows:

[0030] Refining and vacuum degassing treatment reduce the five harmful elements in the steel; continuous casting with low superheat and constant drawing speed, and adopt electromagnetic stirring and light reduction technology to ensure the internal quality of the ф900*1350mm oval...

Embodiment 2

[0036] The thickness of the plastic mold steel thick plate suitable for high flaw detection requirements involved in this embodiment is 220mm, and its chemical composition is calculated by mass percentage: C: 0.42%, Si: 0.26%, Mn: 1.55%, P: 0.006%, S : 0.003%, Cr: 2.5%, Mo: 0.25%, and the balance is Fe and unavoidable impurity elements.

[0037] The manufacturing process of the steel plate is as follows:

[0038] Production process: Converter steelmaking → refining → vacuum degassing → ф900*1350mm oval billet continuous casting → slow cooling → heating in soaking furnace → rolling → heat treatment → finishing → inspection → storage.

[0039] The specific operation of the main process is as follows:

[0040] Refining and vacuum degassing treatment reduce the five harmful elements in the steel; continuous casting with low superheat and constant drawing speed, and the use of electromagnetic stirring and light reduction technology to ensure the internal quality of the ф900*1350mm...

Embodiment 3

[0046] The thickness of the plastic mold steel thick plate suitable for high flaw detection requirements involved in this embodiment is 200mm, and its chemical composition is calculated by mass percentage: C: 0.40%, Si: 0.25%, Mn: 1.60%, P: 0.005%, S : 0.003%, Cr: 2.4%, Mo: 0.23%, and the balance is Fe and unavoidable impurity elements.

[0047] The manufacturing process of the steel plate is as follows:

[0048] Production process: Converter steelmaking → refining → vacuum degassing → ф900*1350mm oval billet continuous casting → slow cooling → heating in soaking furnace → rolling → heat treatment → finishing → inspection → storage.

[0049] The specific operation of the main process is as follows:

[0050] Refining and vacuum degassing treatment reduce the five harmful elements in the steel; continuous casting with low superheat and constant drawing speed, and adopt electromagnetic stirring and light reduction technology to ensure the internal quality of the ф900*1350mm oval...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com