TiO2 doped material, preparation method of TiO2 doped material and application of TiO2 doped material

A technology of doping material and range, applied in the field of solar cells, can solve the problems of inability to absorb near-infrared light, large energy loss of incident light, hindering the improvement of cell efficiency, etc., to expand the spectral response range, uniform size distribution, and improve cell conversion. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

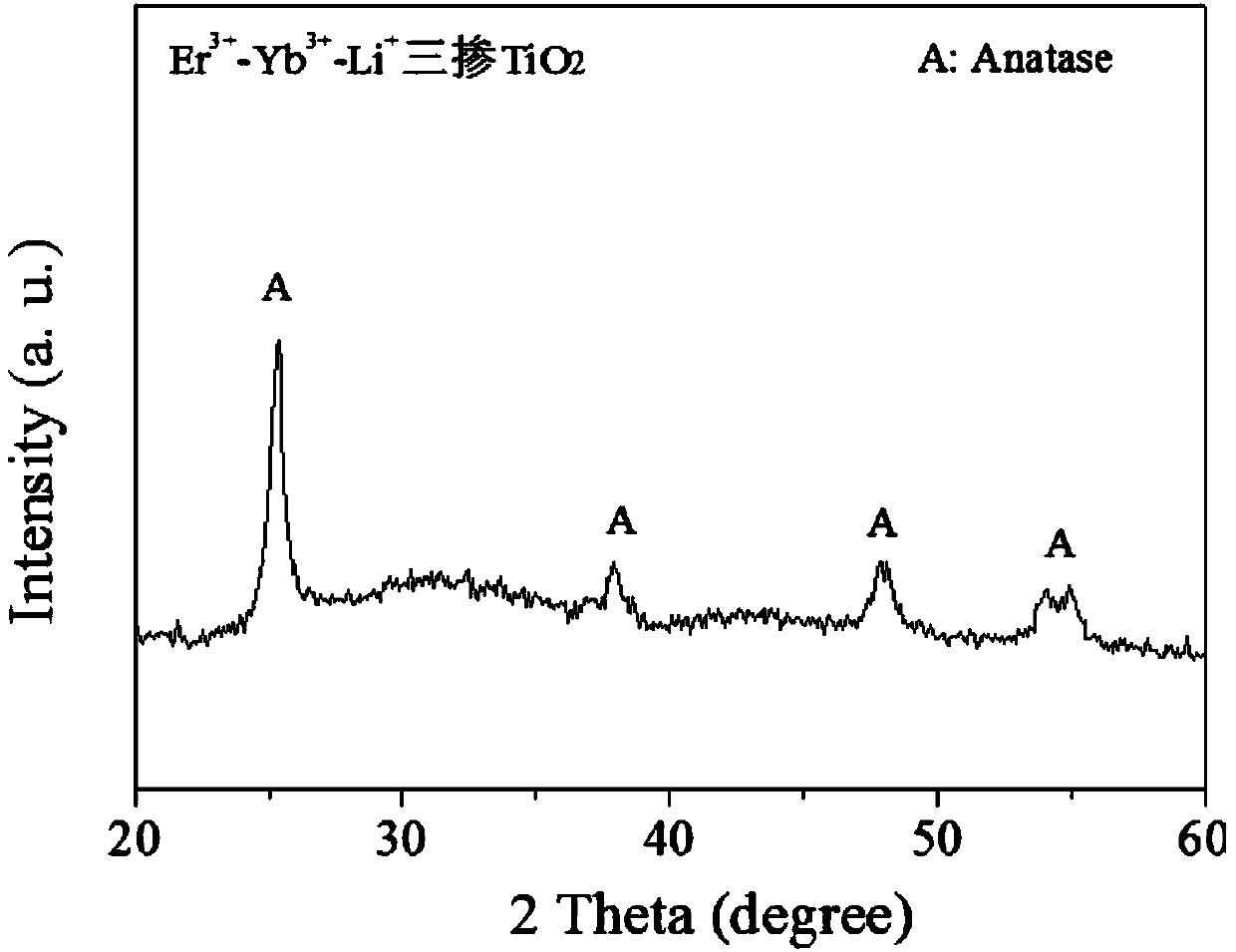

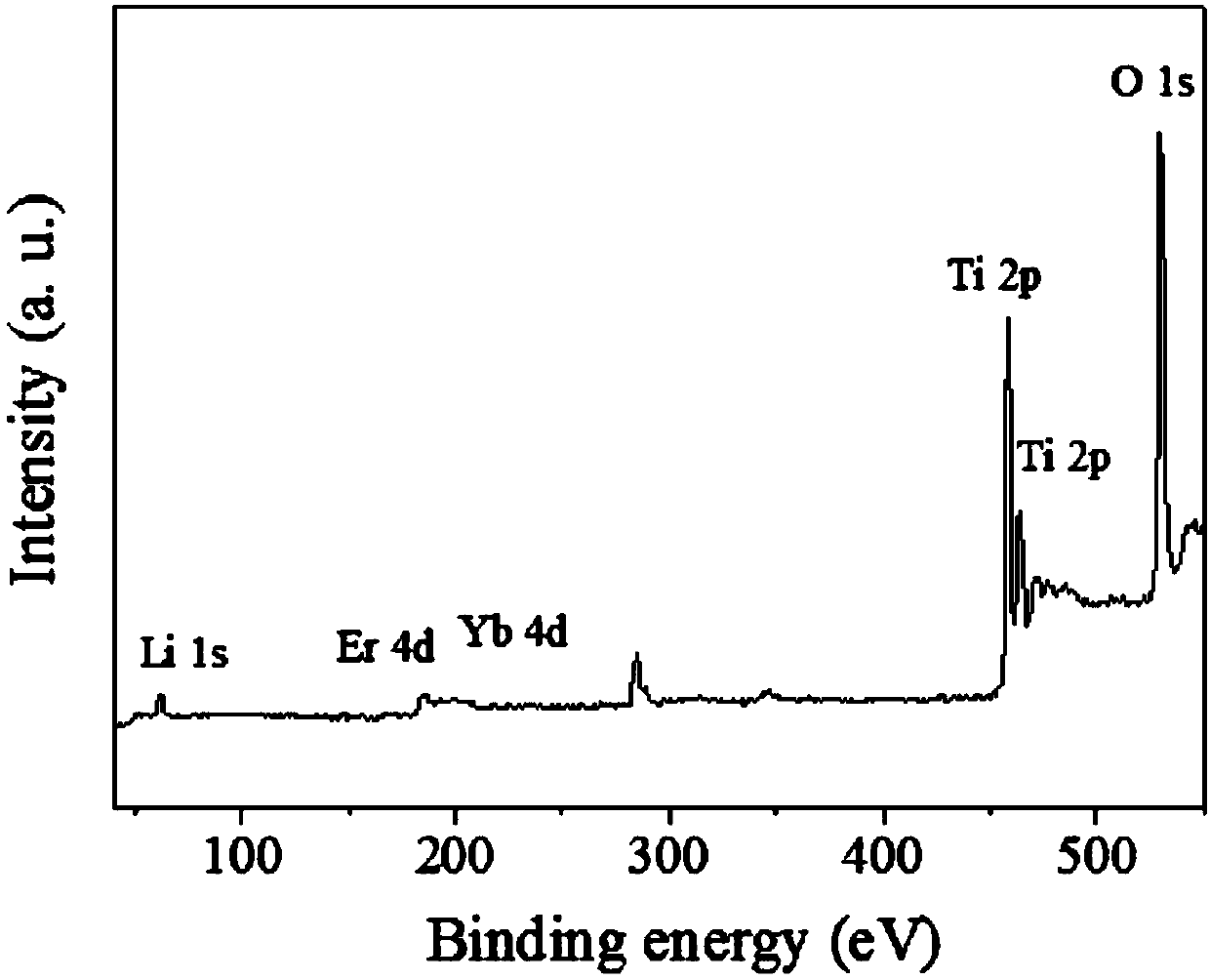

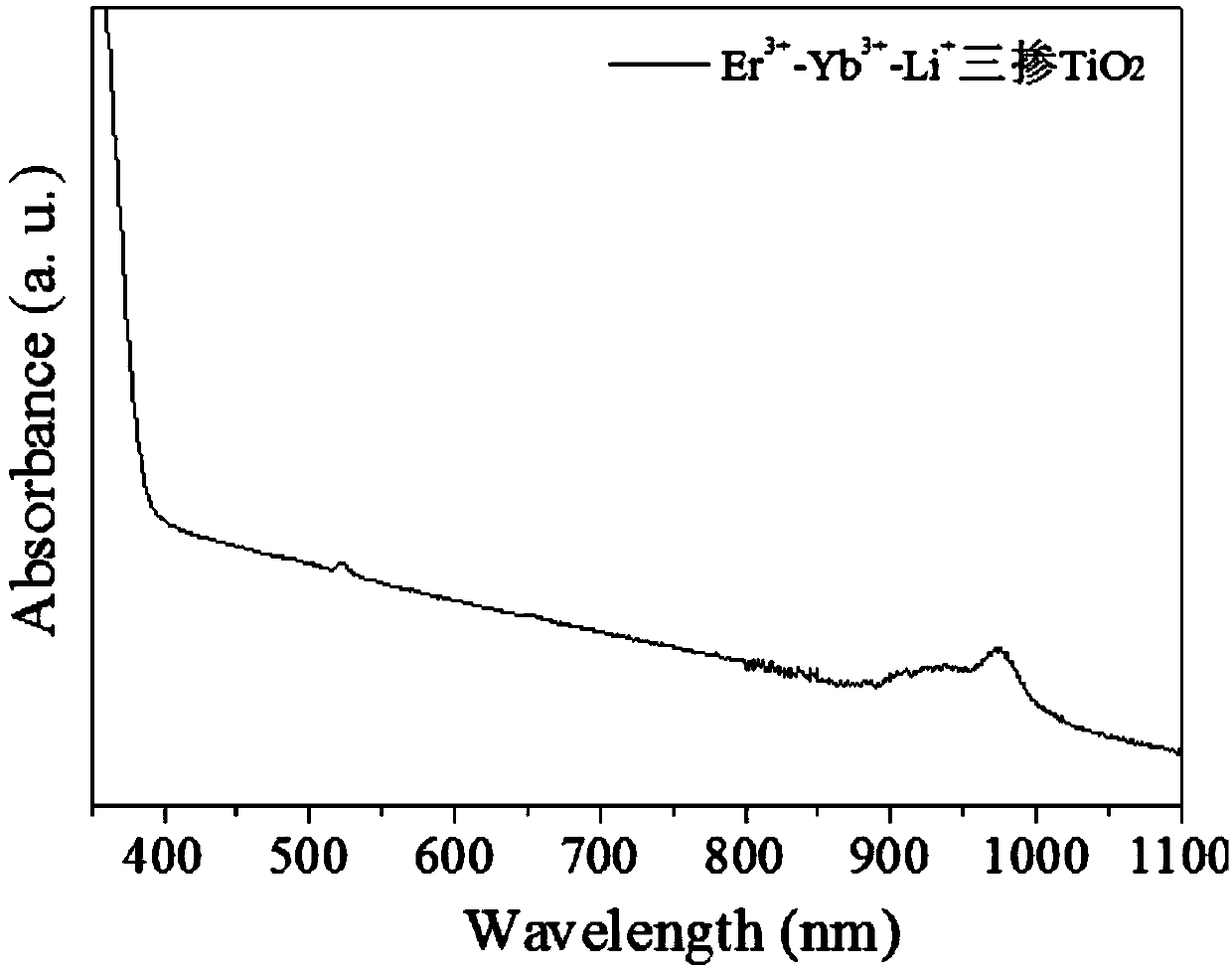

[0044] Example 1. TiO 2 Preparation of doped materials

[0045] (1) Preparation of solution A: 0.5 ml of tetrabutyl titanate and 0.15 ml of acetylacetone were mixed and stirred for 1 hour, and then 7 ml of isopropanol was added.

[0046] (2) Preparation of solution B: Add 0.03ml of nitric acid and 0.07ml of deionized water into 2.7ml of isopropanol, mix and stir for 1 hour.

[0047] (3) Add solution B dropwise to solution A, and magnetically stir for 7 hours to obtain light yellow TiO 2 Precursor solution C.

[0048] (4) Er(NO 3 ) 3 ·5H 2 O, Yb(NO 3 ) 3 ·5H 2 O and LiNO 3 Add solution C to obtain mixed solution D, so that the molar ratios of Er, Yb, Li and Ti in the mixed solution are 0.5:100, 10:100, and 20:100, respectively. Stir magnetically for 2h to dissolve completely.

[0049] (5) Remove the solvent and dry the solution D at 100° C. for 12 hours. Then anneal at 500°C for 30 minutes (can be selected between 30 and 90 minutes) to obtain TiO 2 doped material. ...

Embodiment 2

[0052] Embodiment 2. Preparation of perovskite solar cells

[0053] (1) Cleaning the conductive glass (FTO): put the conductive glass in acetone, isopropanol and ethanol in sequence, ultrasonically clean it for 30 minutes each, and then irradiate it with UV for 20 minutes.

[0054] (2) Add 350 μl of isopropyl titanate to 5 ml of absolute ethanol, then add a small amount of HCl (concentration: 0.013M), mix and stir for 2 hours to obtain a dense layer precursor solution. Then the precursor solution was spin-coated on the FTO at a speed of 2000 rpm, and annealed at 500° C. for 30-60 min to obtain a conductive glass with a dense layer.

[0055] (3) TiO 2 The slurry (Dyesol 30NR-D) was diluted with absolute ethanol (1:6, mass ratio), and the diluted TiO 2 The slurry is spin-coated on the dense layer at a speed of 4000 rpm, and annealed at 450° C. for 30 minutes (30 to 60 minutes can be selected) to obtain a conductive glass with a mesoporous layer.

[0056] (4) The above prepare...

Embodiment 3-5

[0066] Example 3-5. TiO 2 Preparation of doped materials

[0067] Prepare TiO by the same method as in Example 1 2 The difference of the doping material is that in step (4), the molar ratios of Er, Yb, Li and Ti are respectively 0.5:10:X:100, wherein X is 0, 15, 20 or 25 respectively.

[0068] In step (5), when X is 0, 15, 20 or 25, the solution D is desolvated and dried for 12 hours at 80° C., 90° C., and 120° C. respectively. Then anneal at 450°C, 480°C, and 550°C for 40, 60, and 120 minutes to obtain TiO 2 doped material.

[0069] For the TiO prepared above 2 Doping material, and the TiO prepared in embodiment 1 2 The doped material was analyzed and the results were as follows Figure 5 as shown, Figure 5 are different Li + Doping concentration TiO 2 The up-conversion luminescence diagram of the doped material (Er:Yb:Li:Ti=0.5:10:x:100, x=0,15,20,25), the excitation light source is a 980nm laser. Thanks to Li + The addition of TiO 2 The up-conversion luminescen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com