High-performance and deformation-resistant high polymer material for 3D printing and preparation method of high-performance and deformation-resistant high polymer material

A polymer material and 3D printing technology, applied in the field of 3D printing, can solve the problems of restricting the promotion and application of 3D printing technology, poor structural performance of the printing material itself, and low energy consumption in processing operations, and achieve good thermoplastic forming ability, The effect of improving product quality and performance, good mechanical structure strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

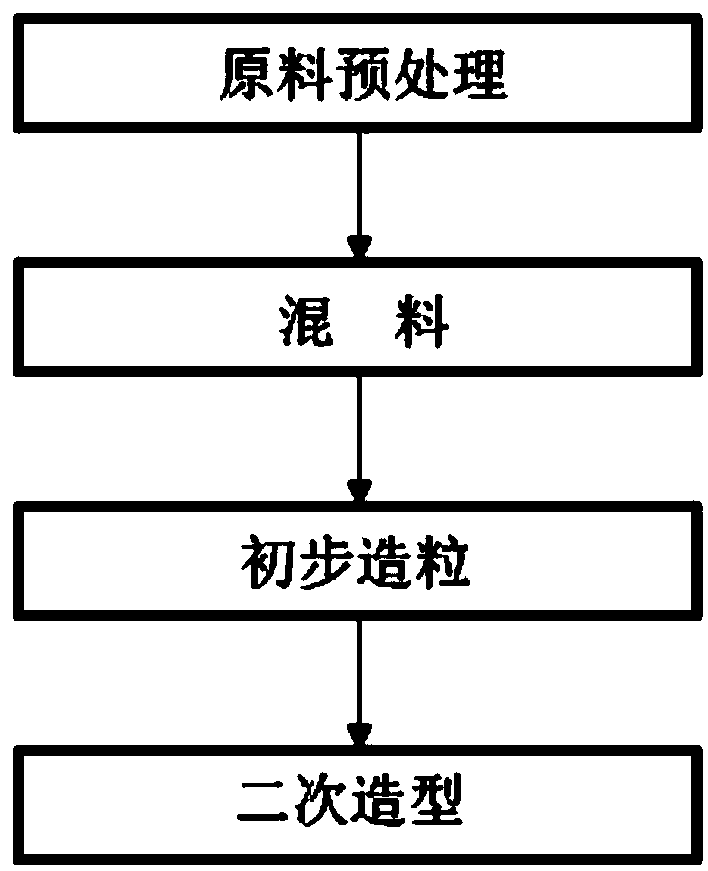

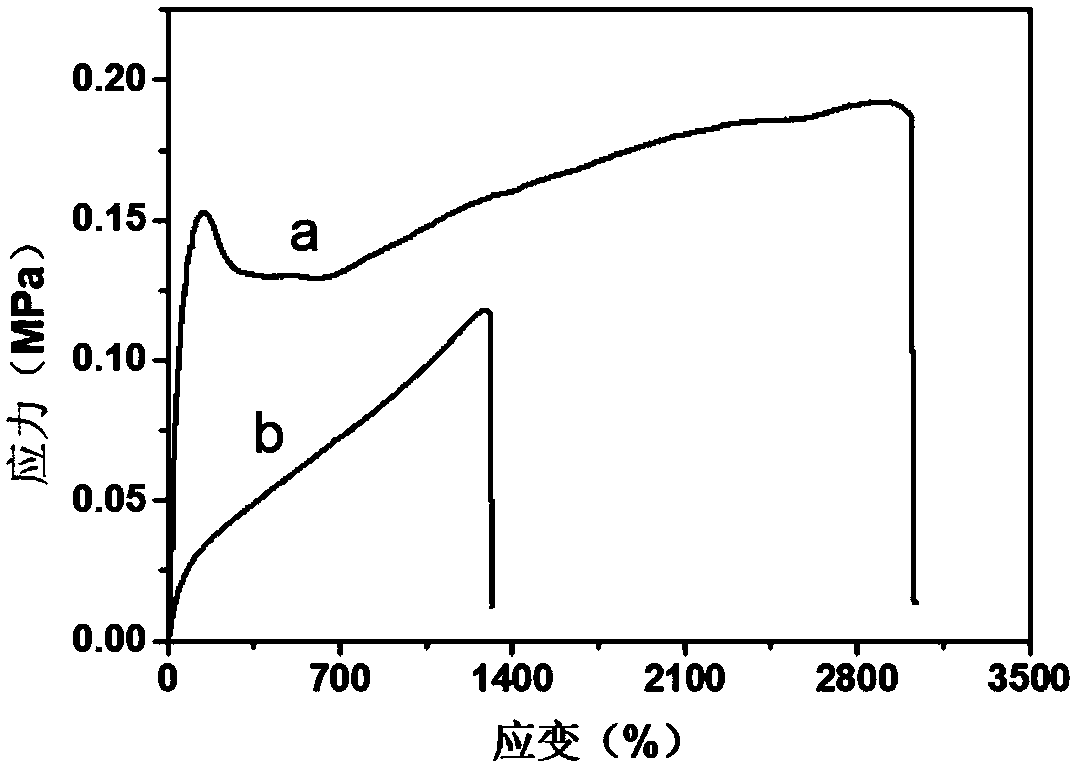

[0023] Such as figure 1 and 2 As shown, a high-performance anti-deformation 3D printing polymer material is composed of the following substances in parts by mass: % hydroxyapatite, 1% calcium carbonate, 0.5% surface modifier, 0.2% antioxidant, ceramic particle powder 1.5%, color powder 0.5%, adhesive 0.1%, diisocyanate bonded crystalline chain extender 1.1%, graphene fiber 0.5%, and the balance is high molecular polymer.

[0024] In this embodiment, the hydroxyapatite is 500-mesh powdered basic calcium phosphate, and the calcium carbonate and ceramic particle powder are both 300-mesh powder structures.

[0025] In this embodiment, the high molecular polymer is polylactic acid.

[0026] In this embodiment, the color powder is lead cadmium yellow.

[0027] In this embodiment, the surface modifier is polyethylene glycol.

[0028] In this embodiment, the antioxidant is antioxidant 1010.

[0029] In this embodiment, the adhesive is a thermosetting elastomer.

[0030] In this ...

Embodiment 2

[0038] Such as figure 1 and 2 As shown, a high-performance anti-deformation 3D printing polymer material is composed of the following substances in parts by mass: calcium carbonate, 2%, surface modifier 1.1%, antioxidant 0.8%, ceramic particle powder 6%, color powder 0.1%, adhesive 0.2%, coupling agent 0.8%, diisocyanate bonded crystalline chain extender 2.3%, graphene fiber 1.5%, and the balance is high molecular polymer.

[0039] In this embodiment, the hydroxyapatite is 200-mesh powdered basic calcium phosphate, and the calcium carbonate and ceramic particle powder are both 300-mesh powder structures.

[0040] In this embodiment, the high molecular polymer is an acrylonitrile-butadiene-styrene terpolymer.

[0041] In this embodiment, the color powder package is red powder.

[0042] In this embodiment, the surface modifier is a silane coupling agent.

[0043] In this embodiment, the antioxidant is anti-oxidant 626.

[0044] In this embodiment, the adhesive is a thermopl...

Embodiment 3

[0052] Such as figure 1 and 2 As shown, a high-performance anti-deformation 3D printing polymer material is composed of the following substances in parts by mass: 0.1% hydroxyapatite, 0.5% calcium carbonate, 1.1% surface modifier, 0.3% antioxidant, ceramic particles Powder 5.5%, color powder 0.4%, binder 0.2%, graphene fiber 0-1.5%, and the balance is high molecular polymer.

[0053] In this embodiment, the hydroxyapatite is powdered basic calcium phosphate of 100-500 mesh, and the calcium carbonate and ceramic particle powder are both of powder structure of 100-500 mesh.

[0054] In this embodiment, the high molecular polymer is polycaprolactone.

[0055] In this embodiment, the color powder is iron blue.

[0056] In this embodiment, the surface modifier is polyethylene glycol.

[0057] In this embodiment, the antioxidant is antioxidant 168.

[0058] In this embodiment, the adhesive is a thermosetting elastomer

[0059] In this embodiment, the coupling agent is a silane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com