A Method for Preventing Corrosion of Aluminum Cans After Cooking

An aluminum can, cooking and sterilization technology, which is applied in chemical instruments and methods, special treatment targets, neutralized water/sewage treatment, etc., can solve the problems that affect the appearance of the product, cannot completely eliminate the white spots on the bottom of the tank, and form white spots on the bottom of the tank, etc. , to achieve the effect of safe method, strong operability and no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

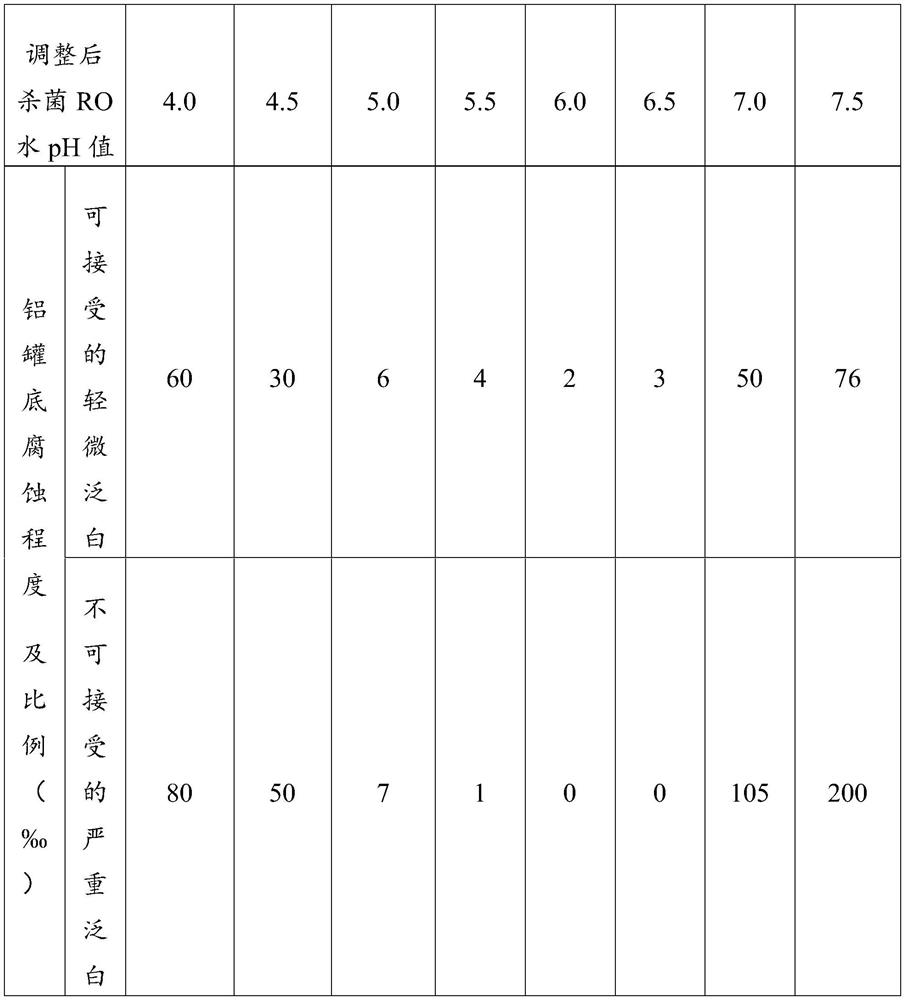

Embodiment 1

[0029] An embodiment of the method for preventing corrosion of aluminum cans after cooking according to the present invention, the method for preventing corrosion of aluminum cans after cooking described in this embodiment is:

[0030] (1) Measure 1000mL of RO water with a graduated cylinder, pour it into a beaker, detect its pH value and record it, then add food-grade citric acid to adjust the pH value of the solution to 5.0, and record the amount of citric acid added.

[0031] (2) According to the amount of sterilizing RO water in the sterilizing kettle, weigh the citric acid that accounts for the same percentage of RO water mass as in step (1), and add it directly to the sterilizing kettle after pre-dissolving; or install it on the pipeline where the sterilizing RO water enters the sterilizing kettle The automatic adding device makes an aqueous solution with a certain concentration of citric acid that accounts for the same percentage of RO water mass as in step (1), and adju...

Embodiment 2

[0034] An embodiment of the method for preventing corrosion of aluminum cans after cooking according to the present invention, the difference between the method for preventing corrosion of aluminum cans after cooking described in this embodiment and Example 1 is that in step (1), adding food-grade lemon acid to make the pH of the solution reach 5.5; in step (2), after adding citric acid, the pH of the sterilized RO water finally reaches 5.5.

Embodiment 3

[0036] An embodiment of the method for preventing corrosion of aluminum cans after cooking according to the present invention, the difference between the method for preventing corrosion of aluminum cans after cooking described in this embodiment and Example 1 is that in step (1), adding food-grade lemon acid to make the pH of the solution reach 6.0; in step (2), after adding citric acid, the pH of the sterilized RO water finally reaches 6.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com