Liquid crystal display device

A technology of a liquid crystal display device and a liquid crystal composition, which is applied in the direction of liquid crystal materials, instruments, chemical instruments and methods, etc., can solve problems such as white spot and uneven orientation, and achieve the effect of preventing white spot and preventing reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

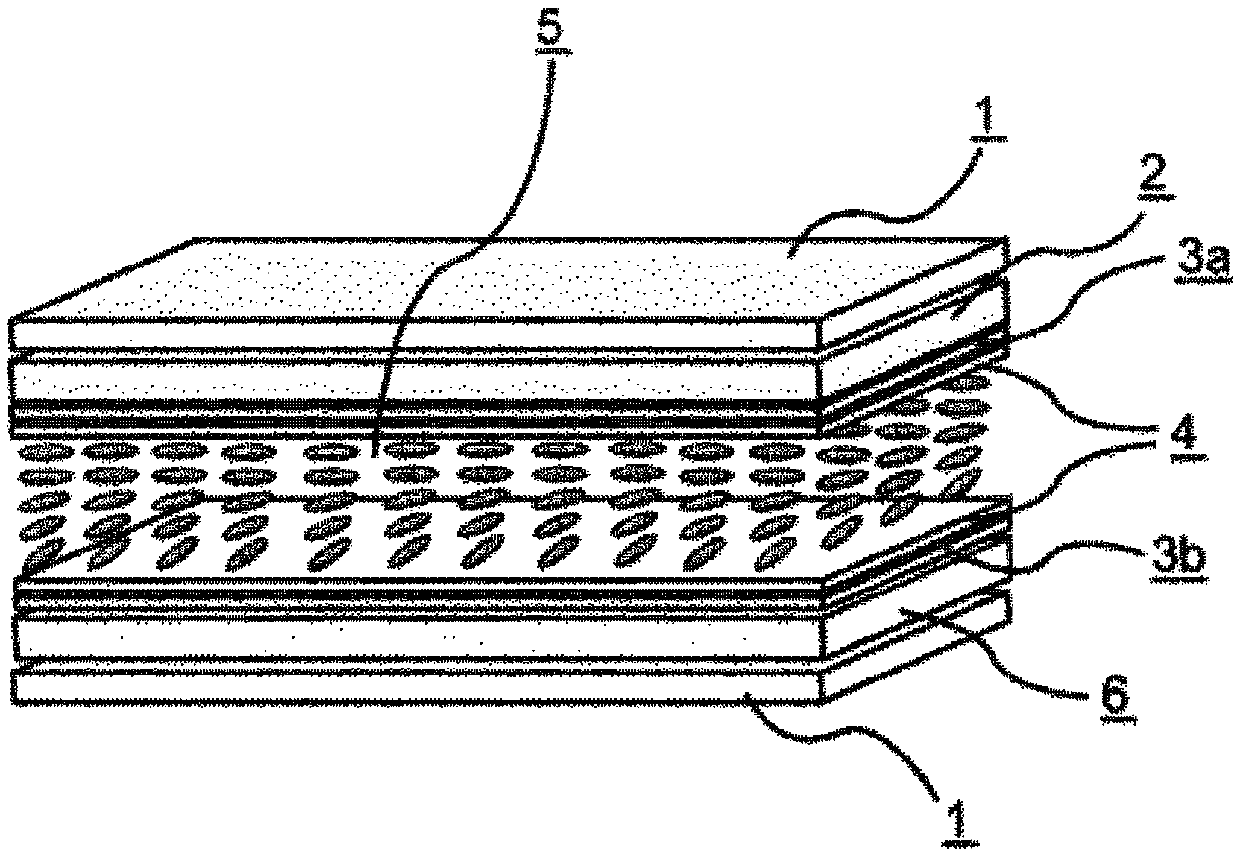

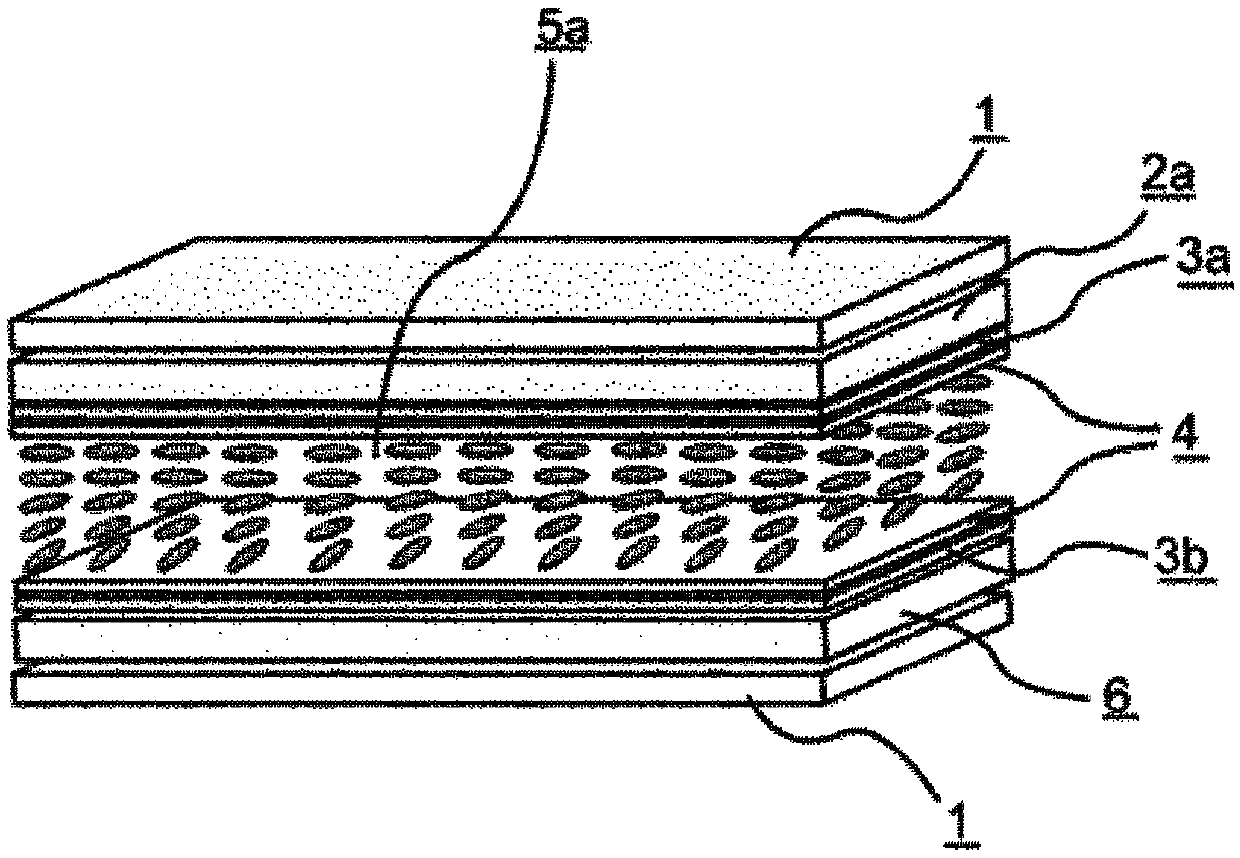

[0410] Make an electrode structure on at least one of the first and second substrates, form a horizontally oriented alignment film on the respective opposite sides, and then perform a weak rubbing treatment to make an IPS unit. Liquid crystal composition 1 shown below was sandwiched between them. The physical property values of the liquid crystal composition 1 are shown in the following table. Next, using the color filters 1 to 5 shown in the table above, the liquid crystal display devices of Examples 1 to 5 were produced (d gap =4.0 μm, alignment film AL-1051). The VHR and ID of the obtained liquid crystal display device were measured. Moreover, the burn-in evaluation of the obtained liquid crystal display device was performed. The results are shown in the following tables.

[0411] [Table 4]

[0412] Liquid crystal composition 1

[0413]

[0414] [table 5]

[0415]

Example 1

Example 2

Example 3

Example 4

Example 5

liquid crysta...

Embodiment 6~15

[0419] In the same manner as in Example 1, the liquid crystal display devices of Examples 6 to 15 were prepared using the color filters 1 to 5 shown in the above table with liquid crystal compositions 2 to 3 shown in the following table interposed, and the VHR thereof was measured. and ID. Moreover, the burn-in evaluation of this liquid crystal display device was performed. The results are shown in the following tables.

[0420] [Table 6]

[0421]

[0422] [Table 7]

[0423]

[0424] [Table 8]

[0425]

[0426] The liquid crystal display devices of Examples 6 to 15 realized high VHR and small ID. Also, in the burn-in evaluation, there was no image sticking, or even if there was, it was at an extremely small and allowable level.

Embodiment 16~30

[0428] In the same manner as in Example 1, liquid crystal display devices of Examples 16 to 30 were prepared using the color filters 1 to 5 shown in the above table by interposing liquid crystal compositions 4 to 6 shown in the following table, and their VHRs were measured. and ID. Moreover, the burn-in evaluation of this liquid crystal display device was performed. The results are shown in the following tables.

[0429] [Table 9]

[0430]

[0431] [Table 10]

[0432]

[0433] [Table 11]

[0434]

[0435] [Table 12]

[0436]

[0437] The liquid crystal display devices of Examples 16 to 30 realized high VHR and small ID. Also, in the burn-in evaluation, there was no image sticking, or even if there was, it was at an extremely small and allowable level.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com