Egg yolk crisp and its production process

A production process, egg yolk cake technology, applied in the field of pastry processing, can solve the problems of too soft taste, sticky teeth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Example 1: Egg yolk crisps, the components included and their corresponding qualities are shown in Table 1, and are prepared through the following steps:

[0072] A. Production of the water-oil skin layer: fully mix high-gluten flour, low-gluten flour, and white sugar powder to form the first mixture; add water to the obtained first mixture, mix well, and knead to form the water-oil skin layer;

[0073] B, making the crisp layer: fully mix the flour and shortening, knead to form the crisp layer;

[0074] C, the production of dough: wrap the water-oil skin layer obtained in step A on the outside of the crispy layer obtained in step B, flatten to 3mm, fold into three, repeat the operation twice, and then flatten to 3mm to form a dough ;

[0075] D, the production of the core layer: select the salted duck egg yolk, and evenly spray the wine (white wine, alcohol content: 38°) on the surface of the salted duck egg yolk, bake at 153°C for 12min, cool to 50°C, turn over , an...

Embodiment 2-6

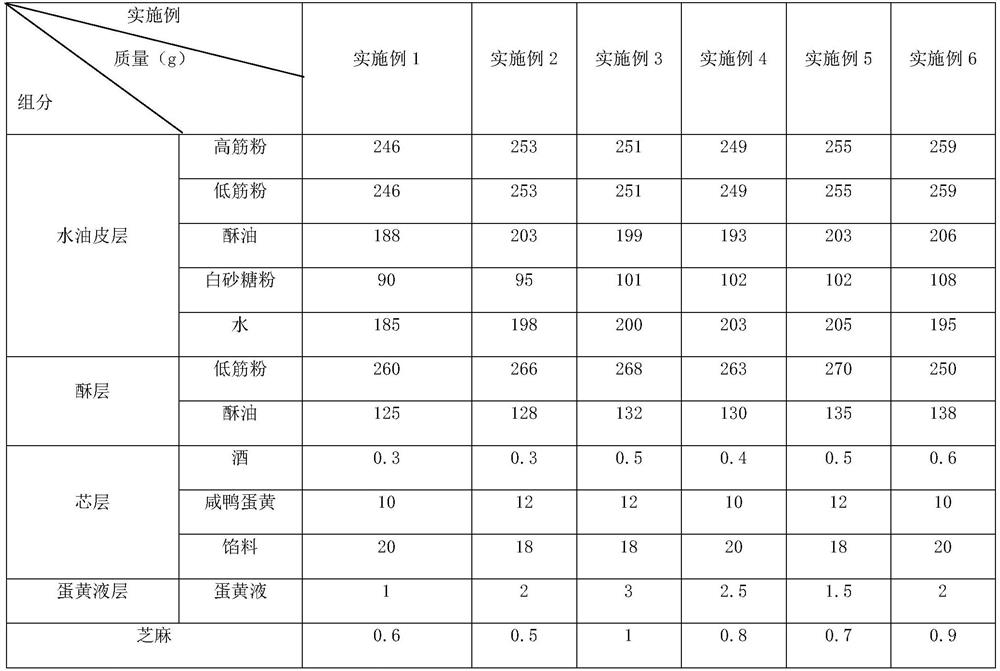

[0080] Examples 2-6: egg yolk crisps, the difference from Example 1 lies in that the included components and their corresponding qualities are shown in Table 1.

[0081] Components included in table 1 embodiment 1-6 and their corresponding quality (water oil cortex, crisp layer in 1kg)

[0082]

Embodiment 7

[0083] Embodiment 7: Egg yolk crisp, the difference from Embodiment 1 is that in step C, it is flattened to 2mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com