Carbonaceous material for negative electrode of nonaqueous-electrolyte secondary battery, and process for producing same

A non-aqueous electrolyte and secondary battery technology, applied in the direction of non-aqueous electrolyte batteries, secondary batteries, battery electrodes, etc., can solve the problem that carbon materials do not have capacity, etc., and achieve the effect of high discharge capacity and excellent charge and discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

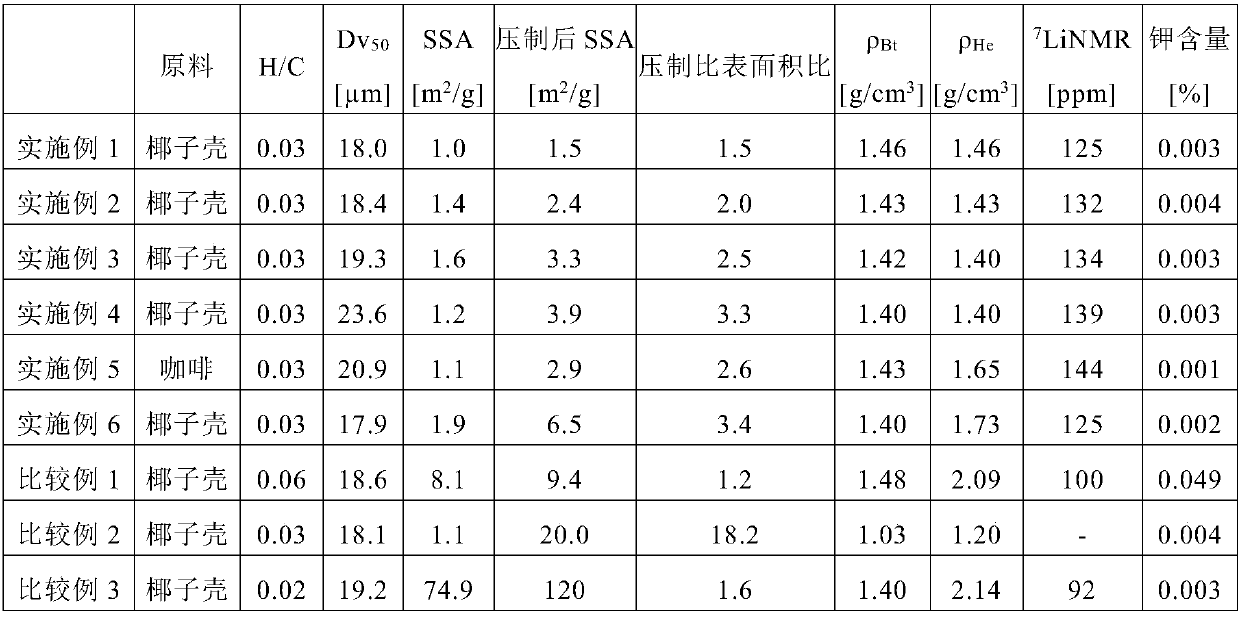

Embodiment 1

[0186]In a nitrogen atmosphere, add sodium hydroxide (NaOH) aqueous solution to the coconut shell charcoal with a particle size of 200 μm (dry distillation at 500 ° C) to impregnate it, and then perform decompression heating and dehydration treatment, thus obtaining a carbon fiber relative to coconut shell carbon. The carbon was impregnated with a carbonaceous precursor of 7.0 wt% NaOH. Next, 10 g of the carbonaceous precursor impregnated with NaOH was heat-treated at 800° C. in a nitrogen atmosphere, and then the nitrogen gas flowing in the reaction tube was replaced with a mixed gas of chlorine and nitrogen, and kept at 860° C. for 1 hour. Next, the flow of chlorine gas was stopped, and the mixture was kept under a nitrogen atmosphere for 30 minutes to obtain charcoal fired from coconut shells. 200 g of the obtained coconut shell pulverized charcoal was pulverized for 20 minutes with a jet mill (AIR JET MILL; MODEL100AFG of Hosokawa Micron Co., Ltd.) to obtain a pulverized c...

Embodiment 2

[0187] Carbonaceous material 2 was obtained in the same manner as in Example 1 except that the impregnation amount of NaOH was changed to 15%.

Embodiment 3

[0189] Carbonaceous material 3 was obtained in the same manner as in Example 1 except that the impregnation amount of NaOH was changed to 18%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com