Nanofiber electrodes and supercapacitors

A nanofiber and electrode technology, which is applied in the field of synthetic self-supporting flexible electrodes, can solve problems such as nanofiber cracking and composite electrodes not showing flexibility, and achieve the effects of reducing production costs, improving area specific capacitance, and reducing reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0126] Example 1: V 0.07 Mo 0.93 o 3 nH 2 O Polymerization of nanofiber paper

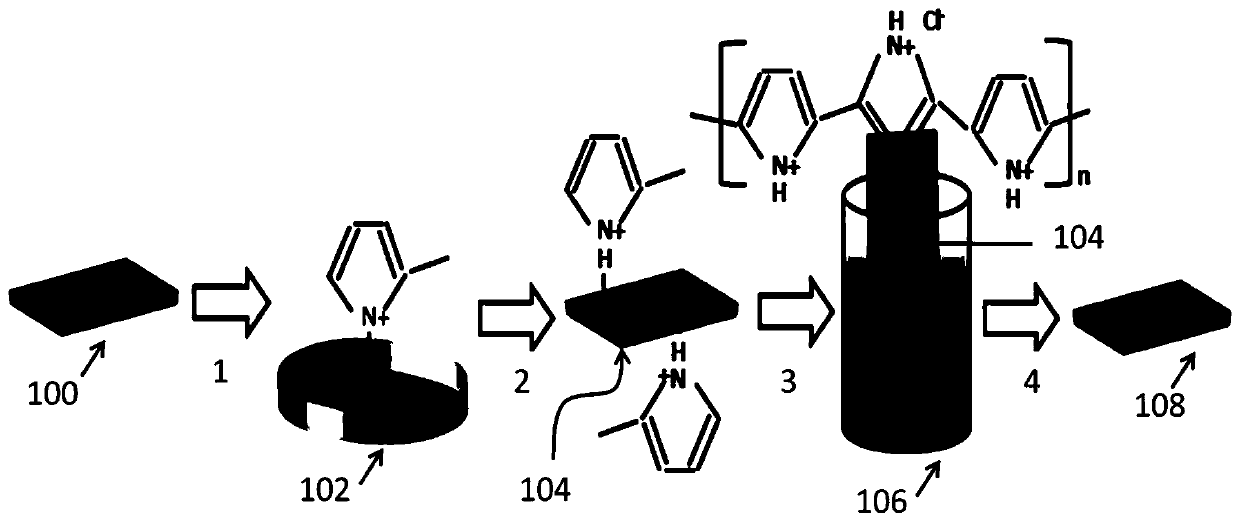

[0127] Polypyrrole-V 0.07 Mo 0.93 o 3 nH 2 The fabrication process of O nanofiber mixed paper (Ppy-VM NHP) electrode is as follows: figure 1 shown.

[0128] First, after using as reaction solvent H 2 o 2 In solution, V was synthesized under hydrothermal conditions 0.07 Mo 0.93 o 3 nH 2 O nanofibers. The resulting solution was then subjected to vacuum filtration (Whatman filter paper) to obtain V 0.07 Mo 0.93 o 3 nH 2 O nanofiber paper (VM NP). The filtration process or system is a vertical filtration flow system in which filter bottles with barbed side arms are used. A filter membrane is placed on top of the bottle. A vacuum pump is then attached to the side arm, and the solution is filtered through the membrane to obtain nanofiber paper. Soak the produced VMNP electrode in HNO 3 medium (to completely oxidize the nanofibers) and dry at room temperature. Although the as-prepa...

Embodiment 2

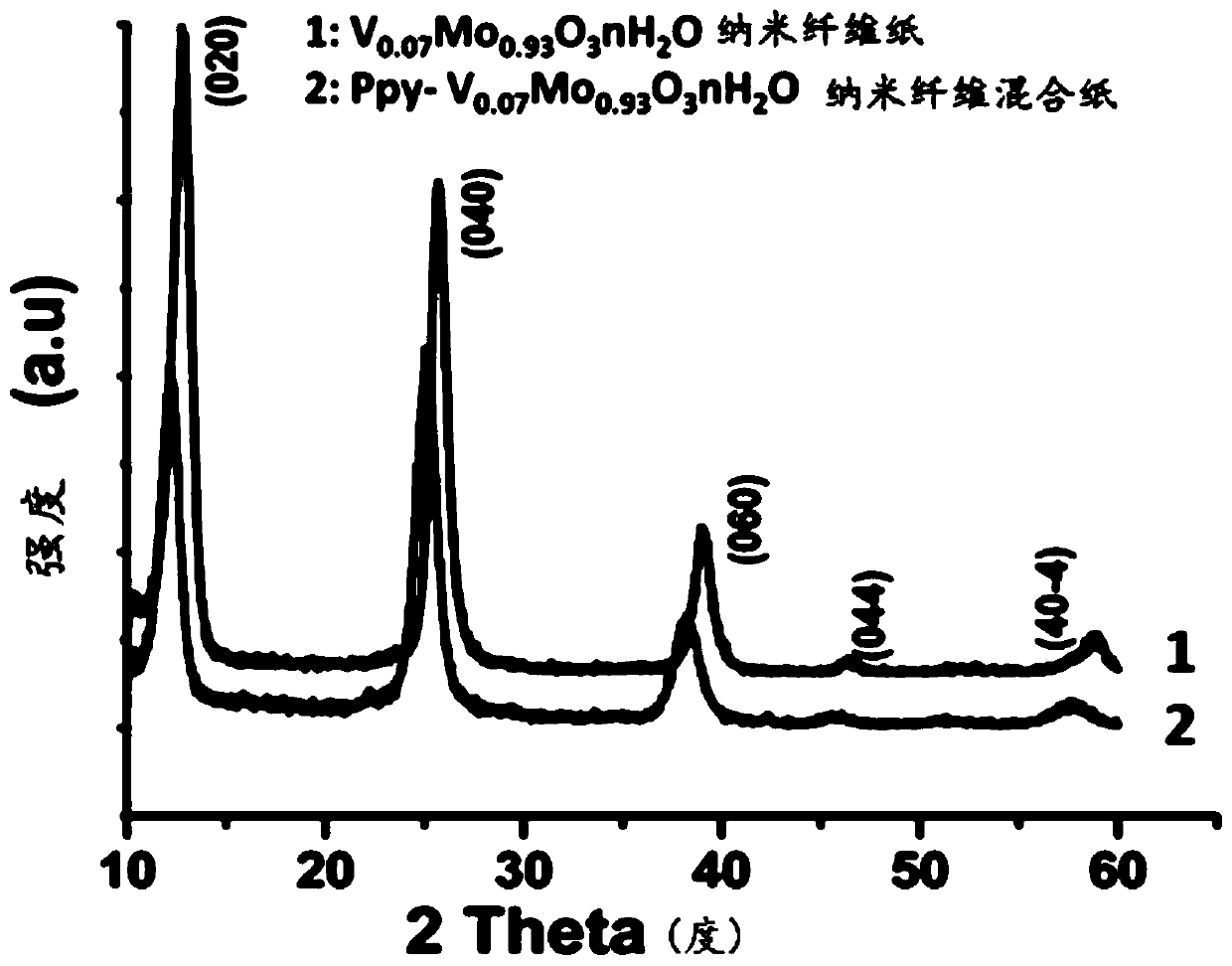

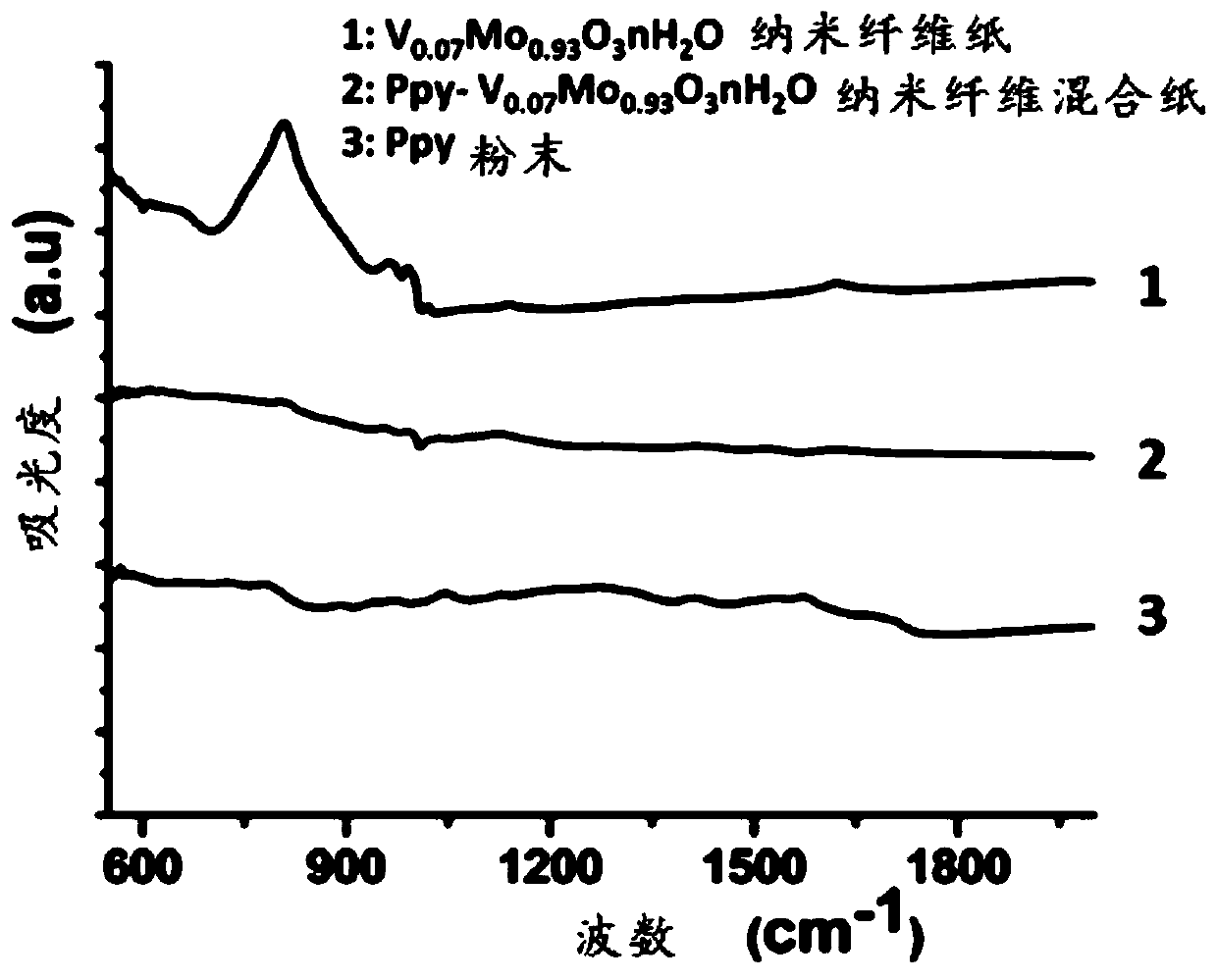

[0130] Example 2: MoO doped with 10 wt% vanadium 3 Nanofiber paper (V 0.07 Mo 0.93 o 3 nH 2 O nanofiber paper)

[0131] Before and after providing polypyrrole, V 0.07 Mo 0.93 o 3 nH 2 The transverse and cross-sectional views of field emission scanning electron microscopy (FESEM) micrographs of O nanofibrous paper are shown in Figures 3A to 3D middle. Figure 3A The wrinkling and bending features associated with nanofiber paper are shown. This is similar to the curved surface obtained by conventional reduced graphene oxide self-supporting paper. To facilitate the interaction of electrolyte ions with the electrode material surface, the presence of wrinkled or wavy features is required. Even after the polymerization of the pyrrole monomer, it was found that the surface of the nanofiber paper did not change, as Figure 3B shown. Cross-sectional FESEM analysis showed that by V 0.07 Mo 0.93 o 3 nH 2 Self-supporting flexible paper electrodes made of O nanofibers com...

Embodiment 3

[0133] Example 3: Mechanical flexibility of Ppy-VM NHPs

[0134] To examine the mechanical properties of Ppy-VM NHP electrodes, their Young's modulus and tensile strength were analyzed by dynamic mechanical analysis (DMA), as Figure 4 shown. Examining the behavior of the Ppy-VM NHP electrode under tensile stress by stress / strain curves (see also Figure 4 ). In the stress / strain curves, the mechanical response (stress / strain) of VM NP and Ppy-VM NHP electrodes can be divided into three parts, namely the initial loading state (E I - volumetric deformation region, represented by points at / close to the beginning of the curve), straightening state (E s - rearrangement region, without any points) and linear elastic state (E E – Regions of bond breakage and deformation, represented by points near / towards the end of the curve).

[0135] In the initial loading state, the Young's modulus of Ppy-VM NHP was found to be lower than that of VM NP, which indicated that the ease of defo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com