Plating bath composition for electroless plating of gold and a method for depositing a gold layer

A technology of electro-gold and compounds, applied in the direction of metal material coating process, coating, liquid chemical plating, etc., can solve the problems of lack of plating rate and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

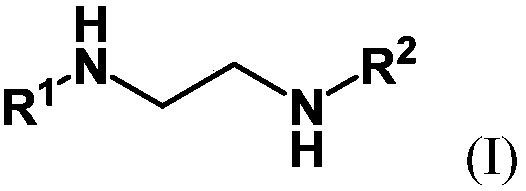

[0067] Embodiment 1 (invention): N 1 ,N 2 -Diisopropylethane-1,2-diamine as a plating enhancer compound

[0068] Prepare a gold plating bath containing the following components by dissolving all components in water:

[0069]

[0070] The substrates were subjected to the following treatment steps by immersing them in the respective solutions with the given parameters (Table 1):

[0071] Table 1: Process steps used for gold plating

[0072]

[0073] After this process step, the thickness of the individual metal layers is measured. Plating rates were calculated as described above.

[0074] Table 2: Containing N 1 ,N 2 - Layer thickness and plating rate of gold plating baths with diisopropylethane-1,2-diamine

[0075]

[0076] The gold layer is lemon yellow. Also, the plating rate is high, well above the expected minimum of 250 nm / h. The layer thickness distribution is also very uniform with a deviation of only 5.6%.

Embodiment 2

[0077] Embodiment 2 (invention): N 1 ,N 2 -Dipropylethane-1,2-diamine as plating enhancer compound

[0078] Repeat the process described in Example 1, wherein the gold plating bath contains 50mmol / L N 1 ,N 2 -Dipropylethane-1,2-diamine instead of 50mmol / L N 1 ,N 2 - Diisopropylethane-1,2-diamine. The results are summarized in the table below:

[0079] Table 3: Contains N 1 ,N 2 - Layer thickness and plating rate of gold plating baths with dipropylethane-1,2-diamine

[0080]

[0081] The gold layer is lemon yellow. Also, the plating rate is high, above the expected minimum of 250 nm / h. The layer thickness distribution is also very uniform with a deviation of only 6.6%.

Embodiment 3

[0082] Embodiment 3 (invention): N 1 ,N 2 -Diethylethane-1,2-diamine as plating enhancer compound

[0083] The treatment described in Example 1 was repeated, wherein the gold plating bath contained N 1 ,N 2 -Diethylethane-1,2-diamine instead of N 1 ,N 2 - Diisopropylethane-1,2-diamine, but at the same concentration. The results are summarized in the table below:

[0084] Table 4: Containing N 1 ,N 2 - Layer thickness and plating rate of gold plating baths with diethylethane-1,2-diamine

[0085]

[0086] The gold layer is lemon yellow. Furthermore, the plating rate is high, well above the expected minimum of 250 nm / h. The layer thickness distribution is also very uniform with a deviation of only 6.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com