Power frequency voltage-withstanding test equipment for automatic insulator in oil

A technology of power frequency withstand voltage and test equipment, which is applied in the direction of testing dielectric strength, etc., can solve problems such as low automation, low efficiency, and scattered processes, and achieve the effects of improving efficiency, reducing costs, and increasing utilization rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

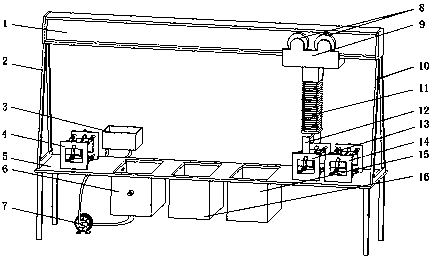

[0022] Such as figure 1Shown is a structural diagram of an automated power frequency withstand voltage test device in insulator oil. The beam 1 is fixed on the workbench 5 through the left beam frame 2 and the right beam frame 10. On the workbench 5, the area to be tested, the ultrasonic cleaning device 15, the air drying device 16, the insulating container 6 and the tested area are arranged in sequence, and the main body of the lifting machine is 9. The rolling pair is formed by the lateral moving wheel 8 and the beam 1. The lateral moving wheel 8 is driven by the lateral moving motor, thereby driving the hoist to move laterally along the beam. The lifting arm 11 is fixed on the main body 9 of the hoisting machine. Driven by a motor, a suspension hook 12 is connected to the end of the lifting arm 11, and both the lateral movement motor and the lifting motor are servo motors and are connected to the control device. The first insulator to be tested 13 and the second insulator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com