A mutual-supporting tension string reticulated shell structure

A shell structure and string net technology, which is applied in the field of inter-supported tension-string reticulated shell structures, can solve the problems of low material utilization, single grid form, poor stability of struts, etc. Aesthetic, beautiful grid style, the effect of reducing internal force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

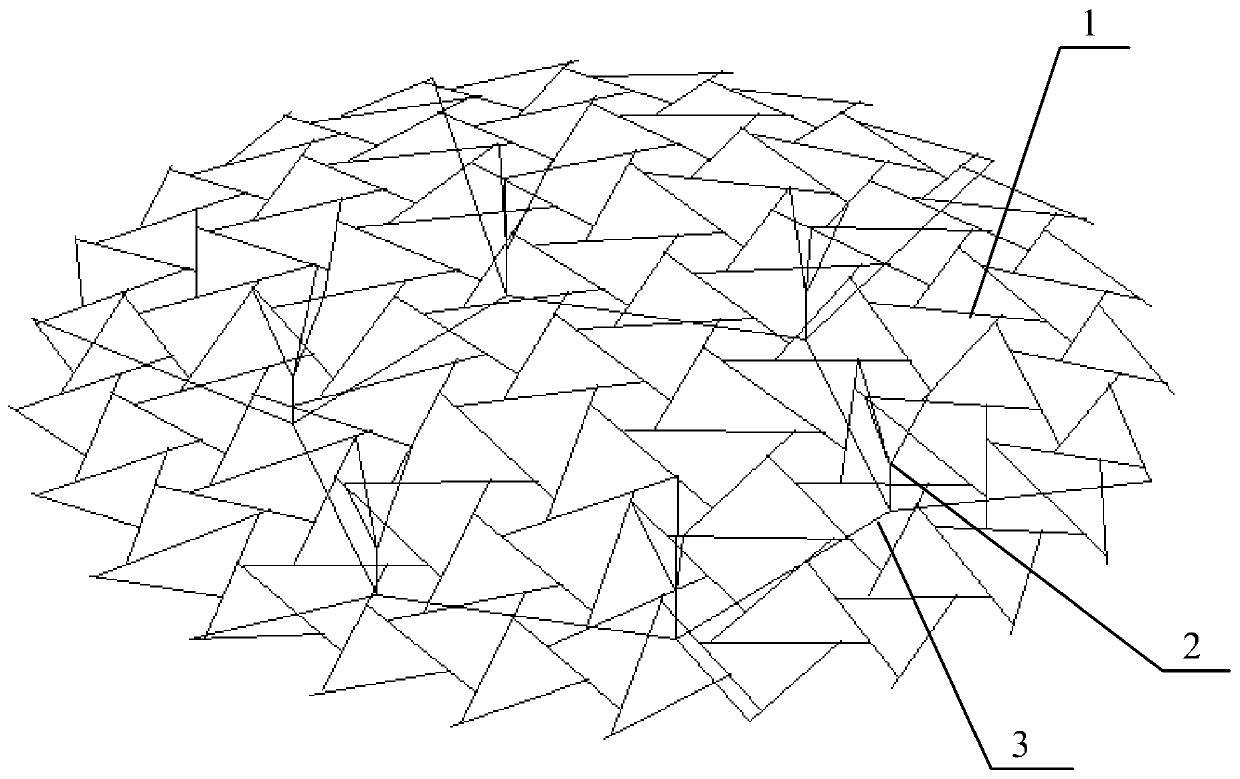

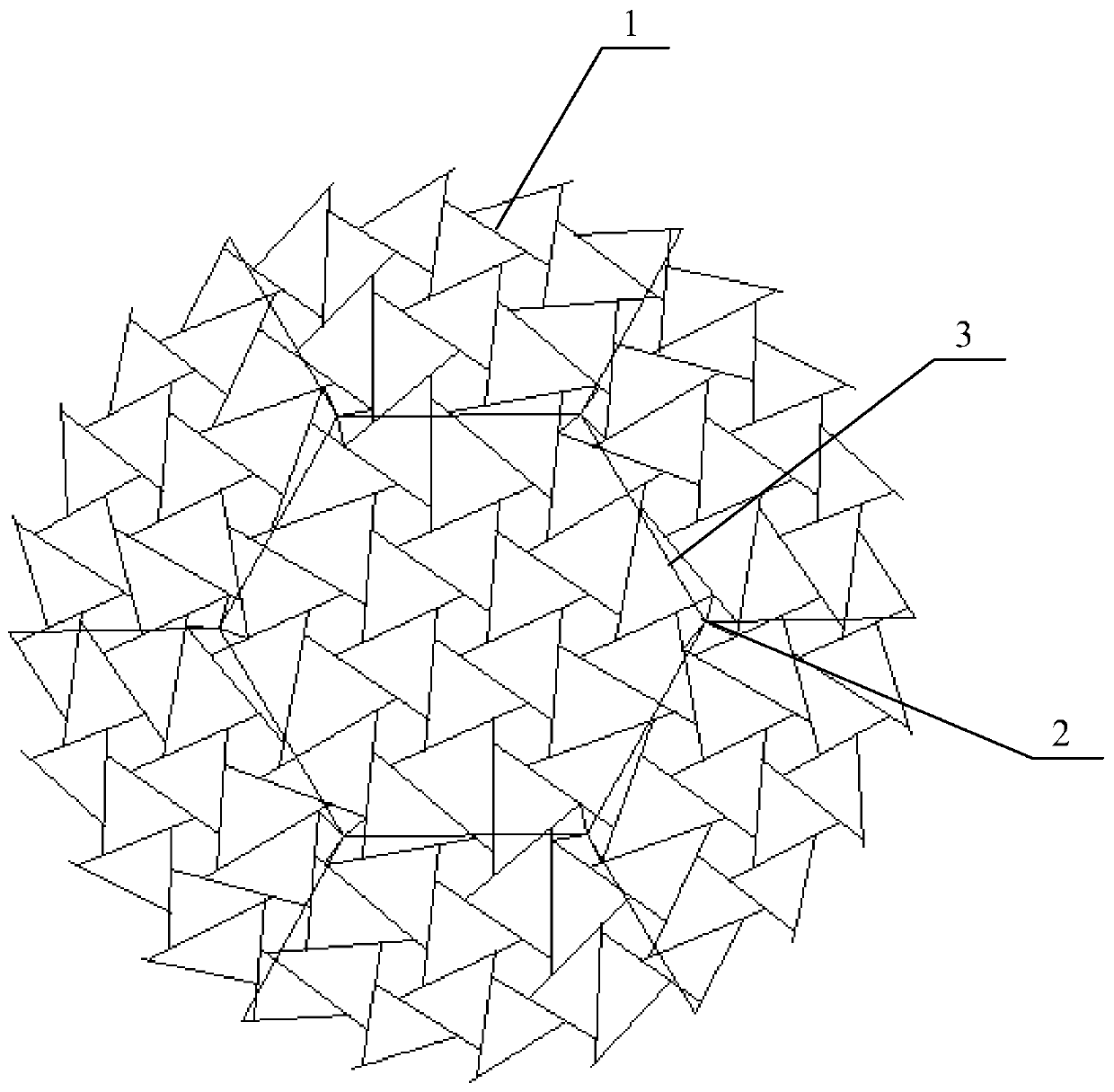

[0031] Specific implementation mode one: combine Figure 1 to Figure 12 This embodiment is described. The inter-supporting string tension reticulated shell structure described in this embodiment includes an upper chord inter-supporting grid assembly 1, a plurality of tree-like strut assemblies 2 and a plurality of lower chord cables 3, and a plurality of tree-like struts Components 2 are uniformly arranged at the lower end of the upper chord mutual supporting grid component 1 along the circumferential direction, the lower ends of two adjacent tree-like strut components 2 are connected by the lower chord cable 3, and the lower ends of each tree-like strut component 2 are respectively connected by the lower chord The cable 3 is connected to the nearest end of the edge of the upper chord intersupporting grid assembly 1 .

[0032] The structure uses the inter-supporting space grid as the upper chord roof, which increases the diversity and change of the roof style, and at the same ...

specific Embodiment approach 2

[0033] Specific implementation mode two: combination Figure 1 to Figure 12 To illustrate this embodiment, the outer edge of the upper chord intersupporting grid assembly 1 described in this embodiment is provided with supports, and the lower chord cables 3 are connected to the support at the end of the edge of the upper chord intersupporting grid assembly 1 through anchor bolts. Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0034] Specific implementation mode three: combination Figure 1 to Figure 12 Describe this embodiment, the tree-shaped strut assembly 2 in this embodiment includes a main strut 2-1 and a plurality of sub-supports 2-2, the main strut 2-1 is arranged in the vertical direction, and a plurality of sub-struts The lower ends of 2-2 are respectively connected to the top ends of the main support rods 2-1, and the upper ends of a plurality of sub-support rods 2-2 are evenly distributed along the circumferential direction, and the upper ends of each sub-support rod 2-2 are respectively connected to the upper chord mutual support network. The lower end face of grid assembly 1 is connected. Other compositions and connection modes are the same as those in Embodiment 1 or 2.

[0035] In this embodiment, the sub-support rod 2-2 is a telescopic support rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com