Solvent-free, non-yellowing, high-transparency and high-brightness polyurethane resin for leather as well as preparation method and application

A polyurethane leather and solvent-free technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor physical properties and poor brightness of synthetic leather, and achieve high folding resistance at room temperature and low temperature, and high transparency Bright appearance, translucent surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

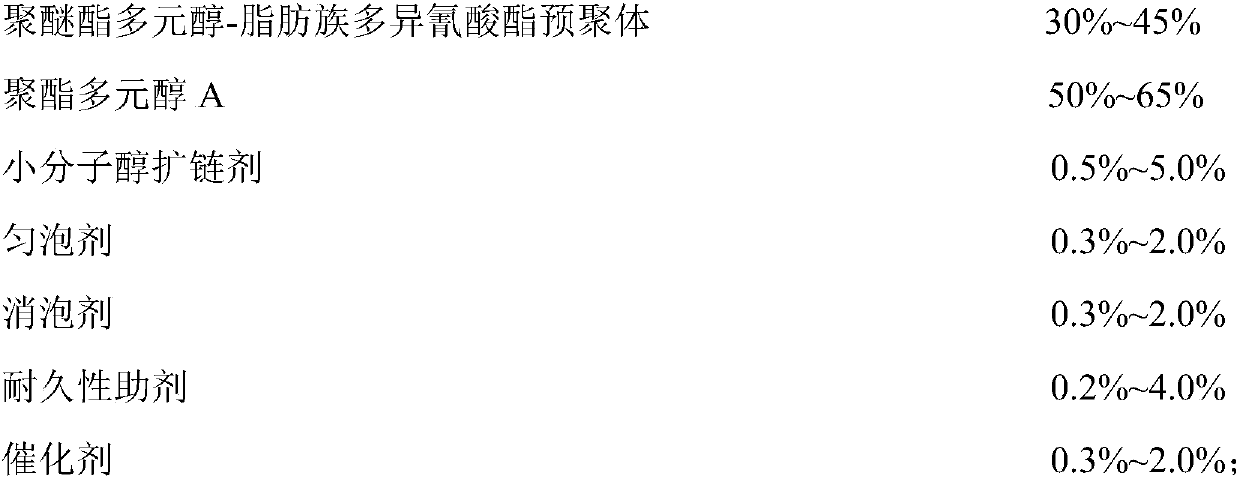

Method used

Image

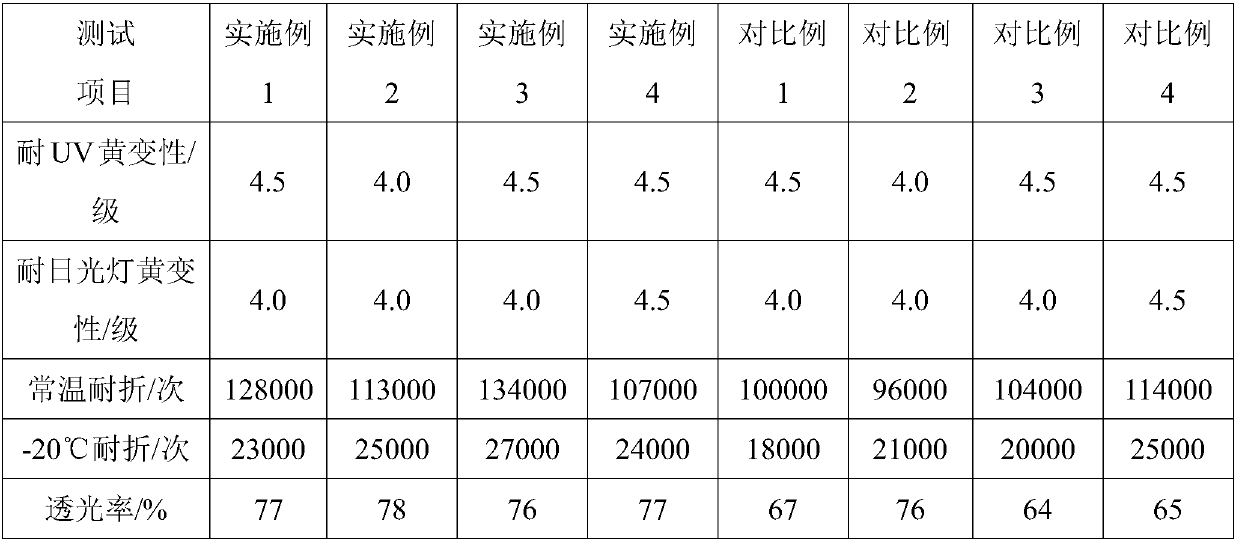

Examples

Embodiment 1

[0055] 30.00kg of polyetherester polyol-isophordione diisocyanate prepolymer (number average molecular weight is 10000, functionality is 2), 64.35kg polyethylene glycol adipate (number average molecular weight is 1000) , 0.65kg of polydiethylene glycol glycerol adipate (functionality of 2.80, number-average molecular weight of 2000), heated to 120 ° C, dehydrated under vacuum conditions of -0.01MPa for 6h, and then cooled to 30°C, add 2.10kg ethylene glycol, 0.90kg trimethylolpropane, 0.70kg silicone foam stabilizer, 0.50kg siloxane defoamer, 0.15kg ultraviolet absorber UV-320, 0.30 Kg of light stabilizer 292, 0.05kg of antioxidant 245 and 0.30kg of organotin metal catalyst were mixed and stirred for 2 hours, and the hydroxyl value and moisture content were detected. When the hydroxyl value reached 125.4mgKOH / g and the moisture content was lower than 500ppm, the Resin A component is obtained, which is sealed and packaged for use.

[0056] In the reactor, drop into the isophor...

Embodiment 2

[0059] 45.00kg of polyetherester polyol-isophordione polyisocyanate prepolymer (number-average molecular weight is 10,000, functionality is 4), 30.00kg of poly(diethylene glycol butylene adipate) (number-average molecular weight is 4) Average molecular weight is 5000), 20.00kg of polydiethylene glycol glycerol adipate (functionality 2.05, number average molecular weight is 5000), heated to 140°C, dehydrated for 5h under vacuum conditions of -0.06MPa, After cooling to 50℃, add 2.47kg 1,4-butanediol, 0.13kg trimethylolpropane, 0.30kg silicone foam stabilizer, 0.30kg siloxane defoamer, 0.45kg ultraviolet absorber Agent UV-320, 0.36kg of light stabilizer 292, 0.09kg of antioxidant 245 and 0.90kg of organotin metal catalyst were mixed and stirred for 2 hours, and the hydroxyl value and moisture content were detected. When the hydroxyl value reached 55.5mgKOH / g, the moisture content was low. At 500ppm, the resin A component is prepared, which is sealed and packaged for use.

[0060...

Embodiment 3

[0063] 38.00kg of polyetherester polyol-isophordione polyisocyanate prepolymer (number-average molecular weight is 30,000, functionality is 3), 40.00kg of polyethylene adipate diol (number-average molecular weight is 3) Molecular weight is 3000), 10.00kg of polydiethylene adipate trimethylol propane diol (functionality is 2.3, number-average molecular weight is 3000) is heated to 130 ° C, under the vacuum condition of -0.04MPa Dehydrated for 5 hours, then cooled to 40°C, added 4.50kg of ethylene glycol, 0.50kg of trimethylolpropane, 2.00kg of silicone foam stabilizer, 2.00kg of siloxane defoamer, and 0.68kg of ultraviolet absorber Agent UV-320, 0.64kg of light stabilizer 292, 0.32kg of antioxidant 245 and 1.00kg of organotin metal catalyst were mixed and stirred for 3 hours, and the hydroxyl value and moisture content were detected. When the hydroxyl value reached 109.1 mgKOH / g, the moisture content was low. At 500ppm, the resin A component is prepared, which is sealed and pac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com