A waterproof weather balloon and its production method

A weather balloon, waterproof technology, applied in the direction of instruments, polyether coatings, coatings, etc., can solve the physical and mechanical properties such as tensile blasting and anti-aging performance, the release height cannot reach the expected height, and the balloon lift-off height Unfavorable problems, to achieve the effect of saving hydrogen, improving the production environment, and excellent hydrophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 1. Preparation of hydrophobic agent

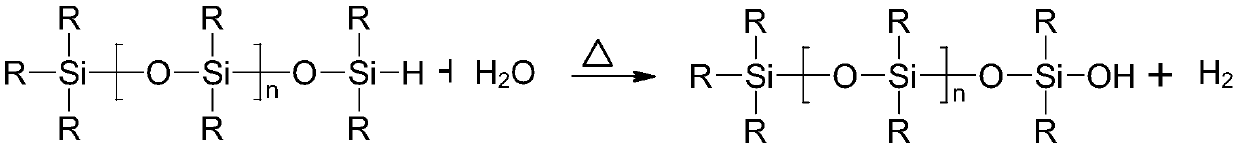

[0052] The 33% organosilicon hydrophobizing agent in this example consists of 12 parts of polymethylhydrogensiloxane with a hydrogen content of 1.5%, a hydrocarbyl molecular weight of 35%, a hydroxyl polydimethylsiloxane with a hydroxyl content of 6.0%, and a hydrocarbyl molecular weight of 35%. 6 parts of siloxane, 4.5 parts of polydimethylsiloxane with a hydrocarbon molecular weight of 35%, 4.5 parts of sorbitan monostearate, 5.9 parts of polyoxyethylene sorbitan monostearate, nonylphenol poly An emulsion product made by mixing and heating 0.1 part of oxyethylene ether and 67 parts of water and then mechanically emulsifying.

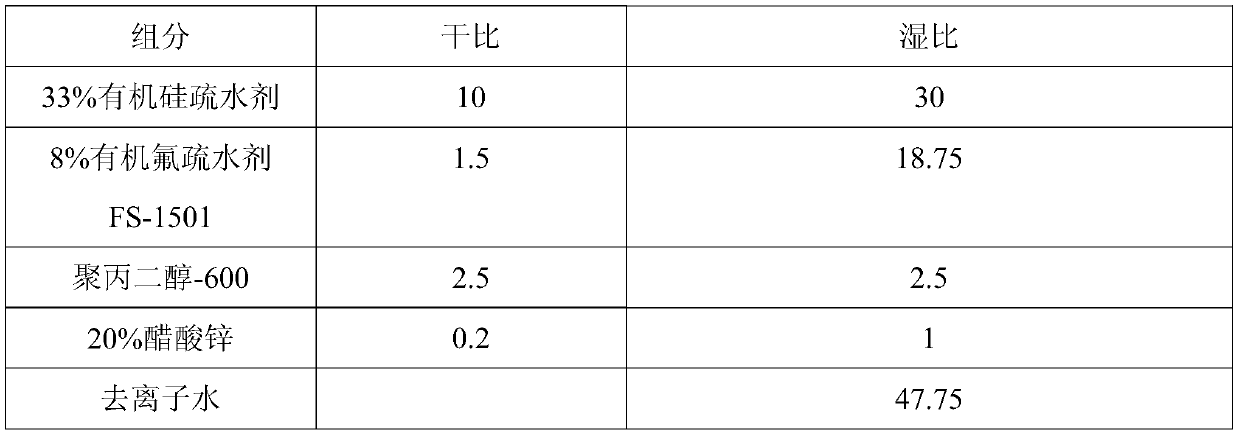

[0053] Content ratio of each component of hydrophobic agent in Table 1 Example 1

[0054] components dry ratio Humidity ratio 33% Silicone Hydrophobic Agent 10 30 Polypropylene Glycol-600 2.5 2.5 20% zinc acetate 0.2 1 Deionized water 66.5

[0055] Note: The d...

Embodiment 2

[0062] 1. Preparation of hydrophobic agent

[0063] The 33% organosilicon hydrophobizing agent in this example consists of 12 parts of polymethylhydrogensiloxane with a hydrogen content of 1.5%, a hydrocarbyl molecular weight of 35%, a hydroxyl polydimethylsiloxane with a hydroxyl content of 6.0%, and a hydrocarbyl molecular weight of 35%. 6 parts of siloxane, 4.5 parts of polydimethylsiloxane with a hydrocarbon molecular weight of 35%, 4.5 parts of sorbitan monostearate, 5.9 parts of polyoxyethylene sorbitan monostearate, nonylphenol poly An emulsion product made by mixing and heating 0.1 oxyethylene ether and 67 parts of water and then mechanically emulsifying;

[0064] The 8% organic fluorine hydrophobic agent in this example consists of 20 parts of methyl hydrogen-containing silicone oil with a hydrogen content of 0.1%, 15 parts of perfluorooctylethyl methacrylate, and 15 parts of dodecyl methacrylate. A product made by free radical emulsion polymerization of monomers.

...

Embodiment 3

[0073] 1. Preparation of hydrophobic agent

[0074] The 33% organosilicon hydrophobizing agent in this example consists of 12 parts of polymethylhydrogensiloxane with a hydrogen content of 1.5%, a hydrocarbyl molecular weight of 35%, a hydroxyl polydimethylsiloxane with a hydroxyl content of 6.0%, and a hydrocarbyl molecular weight of 35%. 6 parts of siloxane, 4.5 parts of polydimethylsiloxane with a hydrocarbon molecular weight of 35%, 4.5 parts of sorbitan monostearate, 5.9 parts of polyoxyethylene sorbitan monostearate, nonylphenol poly An emulsion product made by mixing and heating 0.1 oxyethylene ether and 67 parts of water and then mechanically emulsifying;

[0075] The 14% organic fluorine hydrophobic agent in this example consists of 20 parts of methyl hydrogen silicone oil with a hydrogen content of 1.8%, 16.3 parts of perfluorooctylethyl methacrylate, 8 parts of octadecyl methacrylate, methacrylic acid 7.5 parts of dodecyl esters, the product obtained through the co...

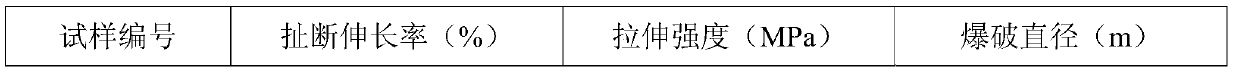

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com