Preparation method and uses of condensate oil aromatization catalyst

A catalyst and aromatization technology, applied in physical/chemical process catalysts, isomerization hydrocarbon production, molecular sieve catalysts, etc., can solve the problems of unstable product quality, large increase in dry gas yield, and low liquid yield , to achieve long-term operation, improve the reaction and regeneration state, and reduce the effect of deep reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

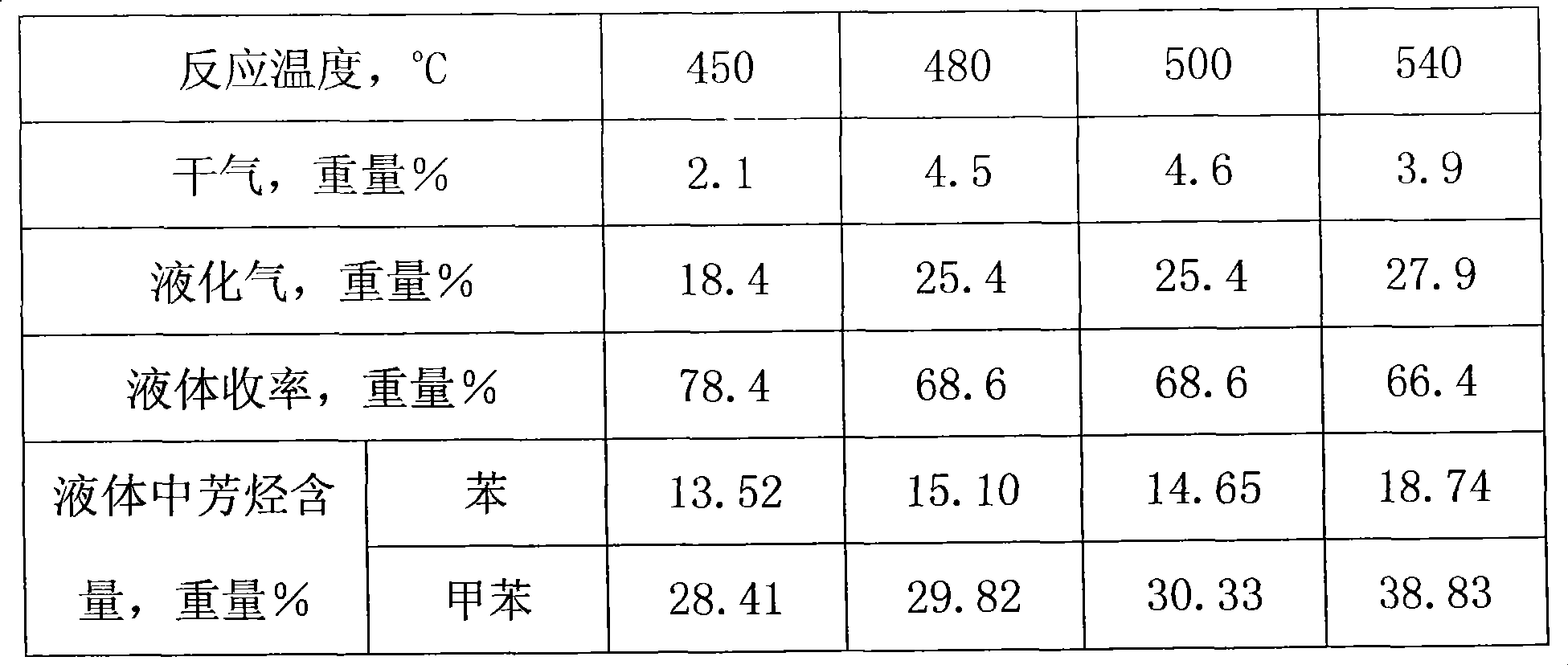

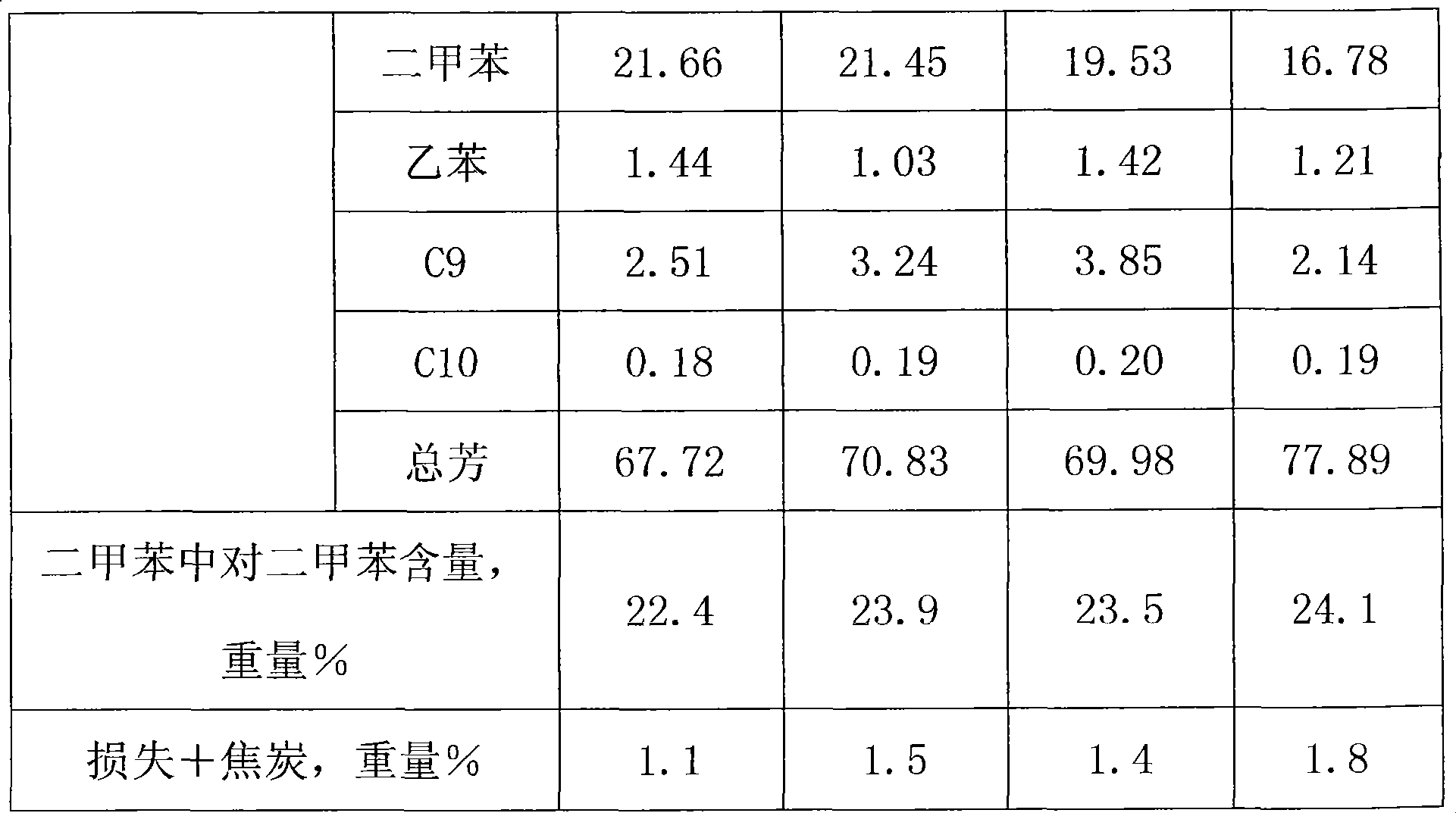

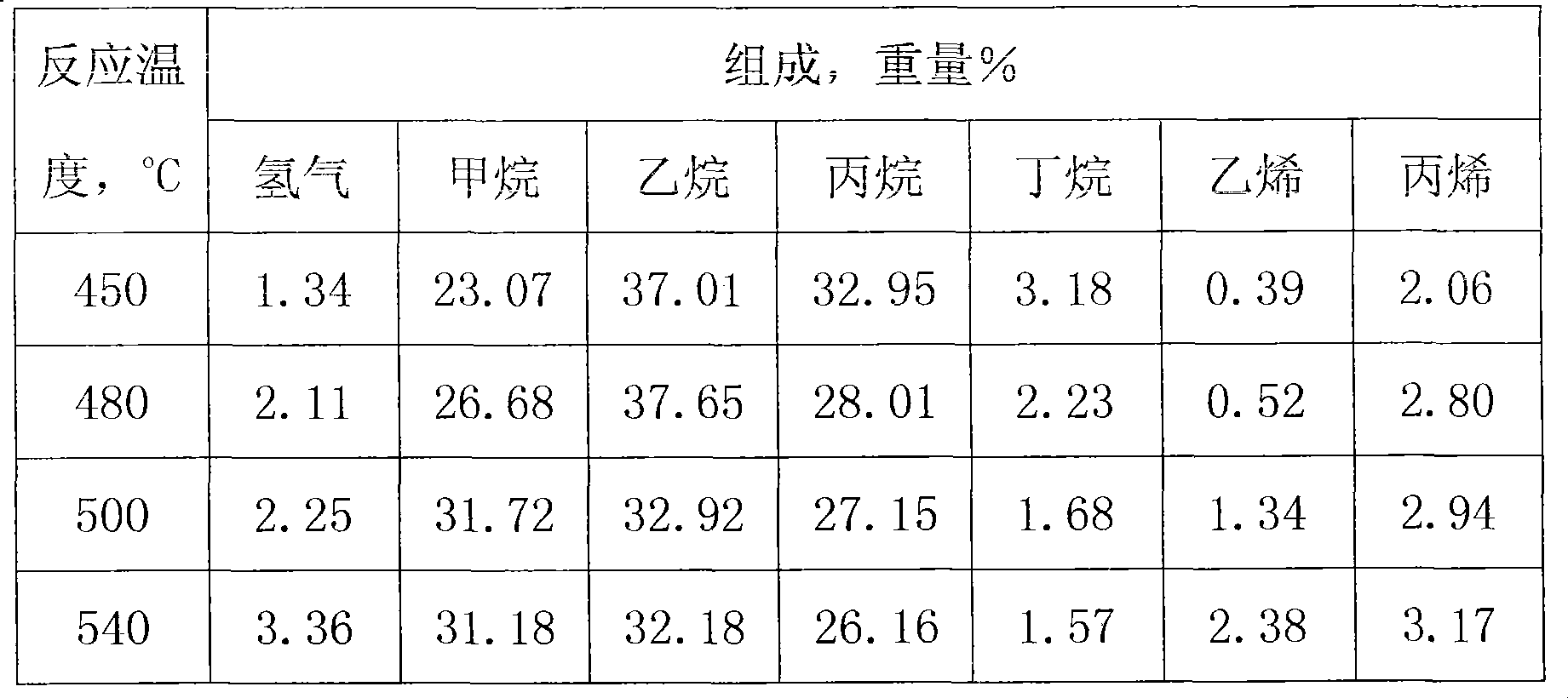

Examples

Embodiment 1

[0024] Preparation of the catalyst of the present invention.

[0025] (1) Get 1500 grams of commercially available nanometer HZSM-5 molecular sieves with a silicon-aluminum ratio of 38, impregnate with 1000 milliliters of a solution containing 11.2 grams of chloroplatinic acid, then dry at 120° C. for 12 hours, and roast at 450° C. for 3 hours;

[0026] (2) Hydrothermal treatment: put the platinum-loaded molecular sieve in step (1) into a tubular reactor, raise the temperature to 520°C in air flow under normal pressure, then change to steam at this temperature for 8 hours, and then Dry air is introduced to purify and cool down, and the total water intake during the steam treatment process is 3000 grams;

[0027] (3) get 700 grams of aluminum sol (pH value is 3.0, containing aluminum oxide 21%), add 100 milliliters of deionized water, make binding agent, then (2) obtains the modified nanometer HZSM-5 molecular sieve, 250 grams of commercially available titanium dioxide and 200...

Embodiment 2

[0031] Prepare other several catalysts B, C by the method for embodiment 1, difference is to change the second metal type and content, be respectively B (nickel 5.0% by weight, use the solution 100 g that contains 26.5 grams of nickel nitrate in (4) step milliliter impregnation), C (5.0% by weight of cobalt, impregnated with 100 milliliters of solution containing 26.0 grams of cobalt nitrate in (4) step).

Embodiment 3

[0033] The catalyst was prepared according to the method of Example 1, except that the amount of pseudo-boehmite mixed with the nanometer HZSM-5 molecular sieve was 250 grams, and the rest of the carrier and metal content were unchanged, and catalyst D was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com