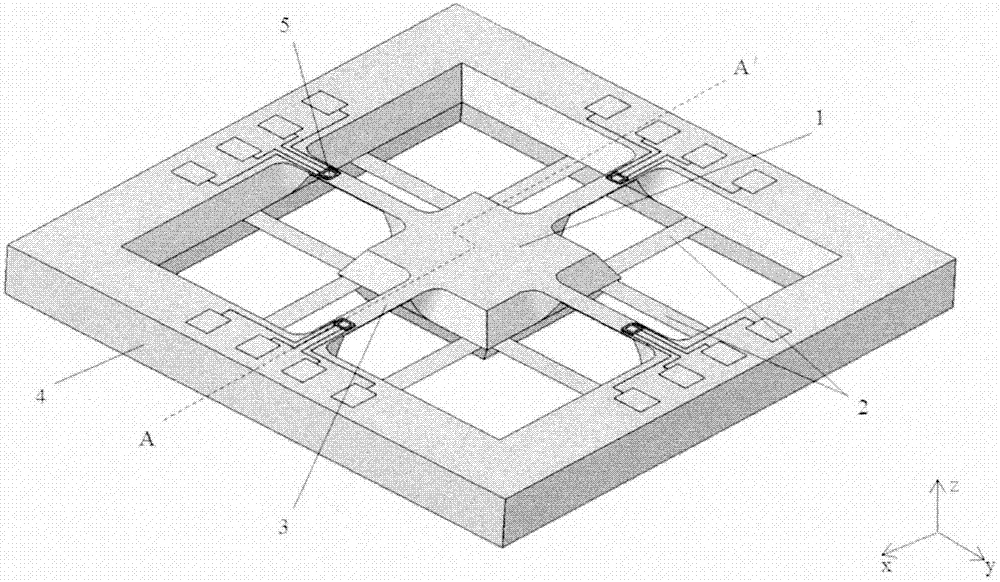

Low cross-axis sensitivity piezoresistive accelerometer structure and manufacturing method thereof

A technology of an accelerometer and a manufacturing method, which are applied in the directions of velocity/acceleration/shock measurement, acceleration measurement, acceleration measurement using inertial force, etc., can solve the problems of high cost, complex process, reduced lateral sensitivity, etc., and achieve small cross-axis sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

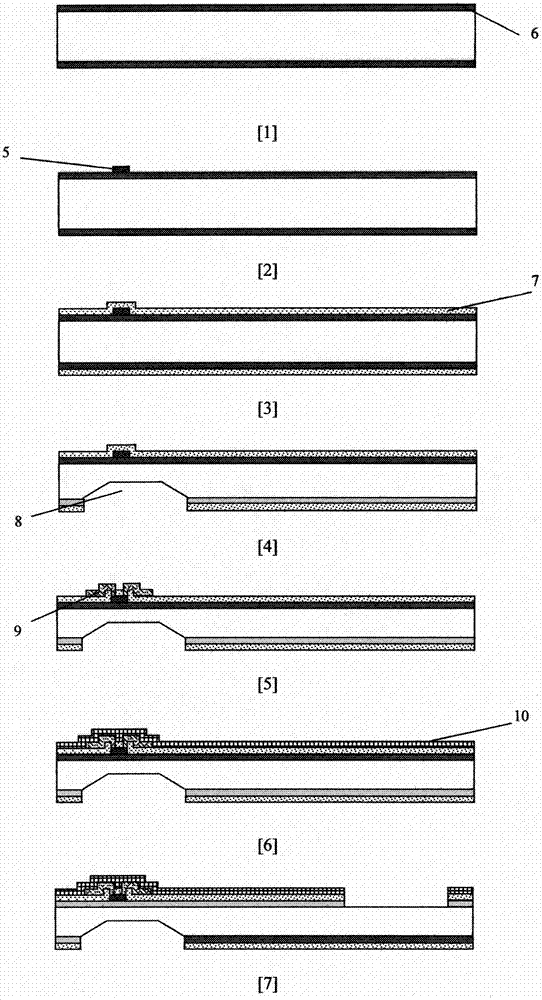

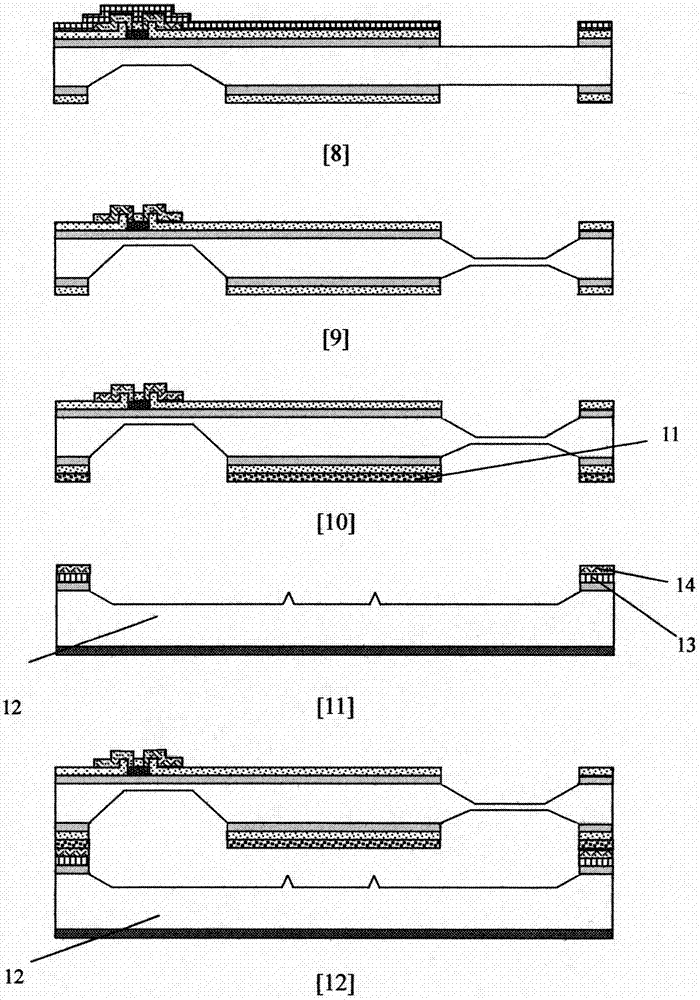

[0034] Embodiment 1: The thickness of the original silicon wafer is 380 microns, the designed thickness of the sensing beam 3 is 5 microns, and the designed thickness of the support beam 2 is 30 microns. The production process determined based on the above data is as follows:

[0035] [1] The original silicon wafer for making the sensor chip is a (100)-sided, double-sided polished silicon wafer with a thickness of 380 microns, and a silicon dioxide film 6 with a thickness of 0.6 microns is produced on the surface of the silicon wafer by thermal oxidation. (see attached figure 2 [1])

[0036] [2] A 0.7-micron polysilicon film was deposited by low-pressure chemical vapor deposition, boron was diffused at high temperature, and the sheet resistance was 300Ω / □, and the varistor 5 was etched by photolithography. (see attached figure 2 [2])

[0037] [3] A 0.25-micron LPCVD silicon nitride film 7 was deposited by low-pressure chemical vapor deposition technology. (see attached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com