However, the desulfurization wastewater is the terminal wastewater of the power

plant, which is affected by many factors, and it is greatly affected by the working conditions and

coal types; the pH is between 4.5-6.5, it is weakly acidic, and the content of

chloride ions is high; the

gypsum particles,

silicon dioxide, iron The content of

suspended solids with aluminum compounds as the main component is high, which may easily cause

fouling of the membrane

filtration device; the content of

total dissolved solids is high, and the range of variation is large, generally 30000-60000 mg / L, and the content of

hardness ions such as Ca2+ and Mg2+ is high , Mercury, lead,

arsenic and other heavy

metal pollutants exceed the standard

The traditional physical and chemical desulfurization wastewater treatment methods commonly used at present can only remove most of the heavy

metal ions, but cannot remove the highly mobile

chloride ions

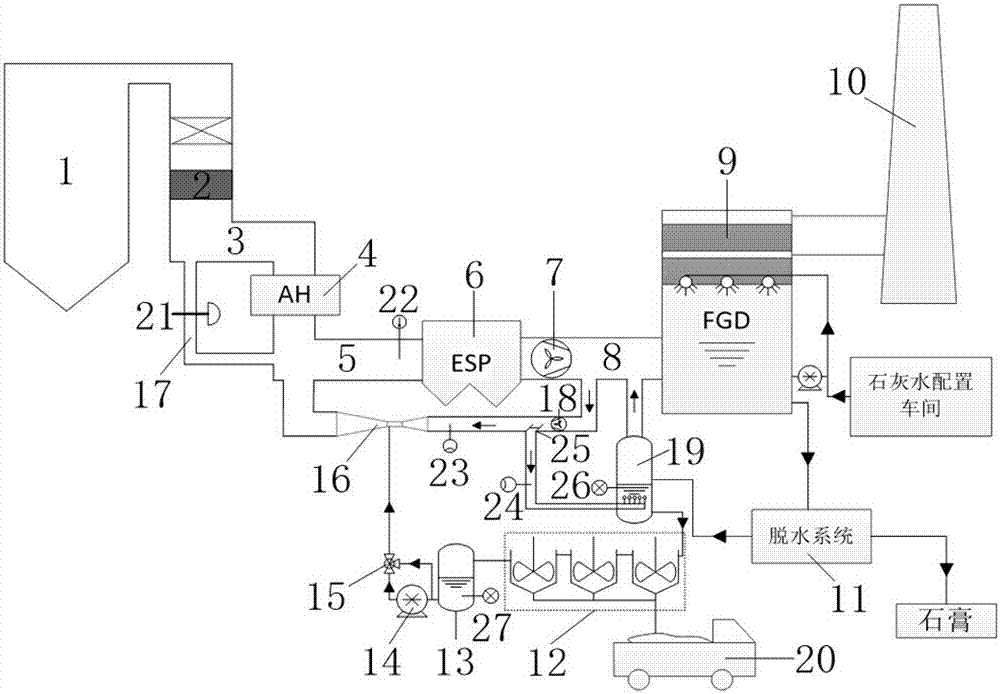

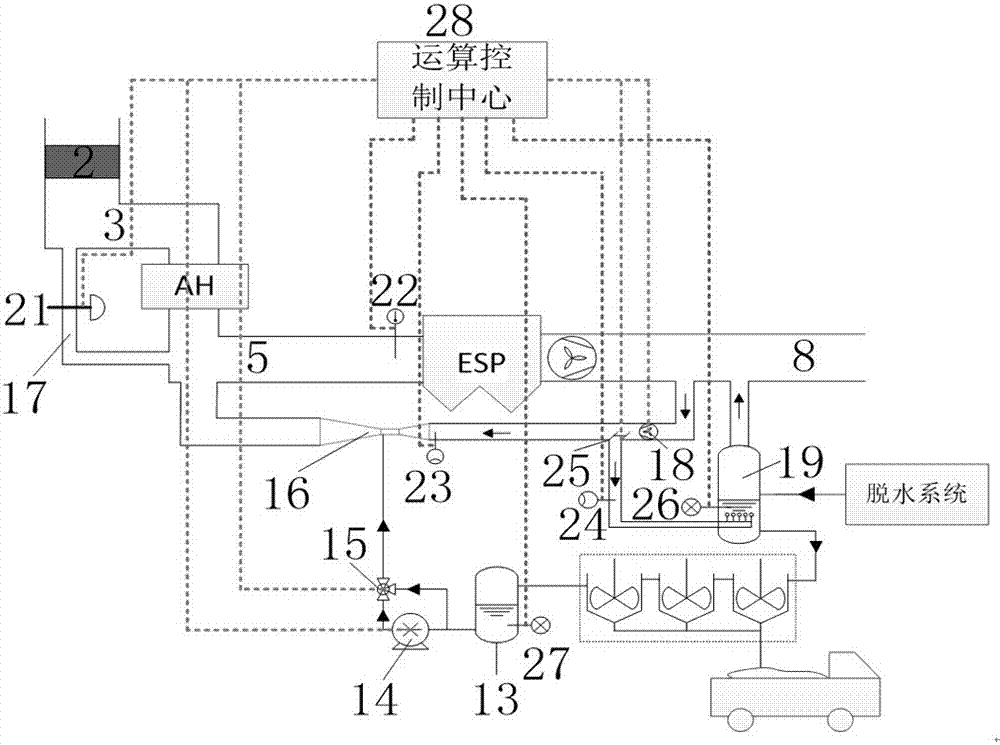

[0003] Aiming at the status quo of desulfurization wastewater with complex

water quality and its difficulty in treatment, the

Chinese patent No. 201710054360.3 discloses a wastewater concentration

system and method based on

liquid column evaporation using

flue gas waste heat. The desulfurization wastewater is sprayed into the In the

evaporation tower, the waste heat of the flue gas in front of the desulfurization tower is used to concentrate the desulfurization wastewater. A

demister is arranged at the outlet of the evaporation tower to remove the liquid droplets in the flue gas. The purpose of desulfurization wastewater concentration reduction, but this method increases the

corrosion of the existing flue; the

Chinese patent No. 201010179796.3 discloses a thermal power

plant wet

flue gas desulfurization wastewater spray evaporation treatment method, the desulfurization wastewater is directly in the power plant Spray evaporation in the flue before the

dust collector to achieve zero

discharge of desulfurization wastewater, but this method directly sprays the desulfurization wastewater without

reduction treatment into the main flue before the

electrostatic precipitator, which increases the

corrosion risk of the

electrostatic precipitator; the patent number is The

Chinese patent of 201510275955.2 discloses a zero-

discharge process and system for desulfurization wastewater. It uses chemical

softening and

microfiltration membrane for pretreatment, adopts

nanofiltration and

reverse osmosis separation, freezes and crystallizes

sodium sulfate decahydrate with a purity of more than 99%, evaporates

Crystallization of

sodium chloride with a purity of 98% also provides a zero-discharge system that can reuse desulfurization wastewater, but the system is lengthy, the

processing steps are cumbersome, and the investment and operating costs are high; the Chinese patent No. 201611008084.9 discloses A system and method for the comprehensive treatment of desulfurization wastewater concentration and flue gas

drying. After the desulfurization wastewater is treated by a traditional triple box, it is concentrated by an

evaporator. The concentrated wastewater is evaporated and crystallized by the heat of the flue gas in the bypass flue, and the air flows through the dust removal. Then it is discharged from the

chimney, but this method directly uses the high-temperature flue gas in front of the

air preheater to evaporate the desulfurization wastewater, and the subsequent

solid evaporated product is collected by a

cyclone dust collector instead of being captured by an

electrostatic precipitator and mixed into the

fly ash. It not only increases the

energy consumption of desulfurization wastewater evaporation, but also its

solid evaporated product needs to be treated as hazardous solid waste due to the enrichment of

heavy metals and other pollutants

The Chinese patent No. 201610031262.3 discloses a method and device for treating desulfurization wastewater by using flue gas waste heat. The desulfurization wastewater discharged from the

slurry dehydration system is directly sprayed into the concentration system transformed from the main flue before the wet desulfurization absorption tower. In this method, the

effluent from the concentration system is directly sent to the main flue in front of the electrostatic precipitator for atomization and evaporation. However, the desulfurization wastewater in this method is not treated by three-box dosing. There are more

calcium,

magnesium and heavy

metal ions in the water, and the

water quality is poor. Not only Increase the risk of

corrosion and

fouling of the main flue before the electrostatic precipitator, and increase the risk of clogging of the mechanical atomization or medium atomization method used

[0004] Treating desulfurization wastewater by evaporation and

crystallization, in order to achieve higher salt separation requirements, often requires

high energy consumption and high economic costs; compared with flue evaporation, on the one hand, the bypass evaporation tower brings relatively high costs to the power plant. Large investment, on the other hand, brings pressure on

land use for power plants that occupy a tight area for their equipment

However, the low treatment capacity of desulfurization wastewater in flue evaporation and the inability to completely evaporate

dryness under

low load limit the development of flue evaporation technology for desulfurization wastewater. 90~120℃) for reduction and concentration, and then use the waste heat of the flue gas before electrostatic precipitator (about 120℃) for atomization and evaporation to

dryness. The

cascade utilization of the waste heat of the flue gas in the power plant realizes desulfurization while reducing the investment of the power plant Zero discharge of waste water

Login to View More

Login to View More  Login to View More

Login to View More