Pump-free organic Rankine cycle power generation system with compression refrigeration efficiency

A technology of Rankine cycle and power generation system, applied in the direction of machine/engine, pump, jet pump, etc., can solve the problems of frequent switching, large difference in height difference requirements, cumbersome control, etc., to reduce condensation temperature, reduce irreversible loss, The effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

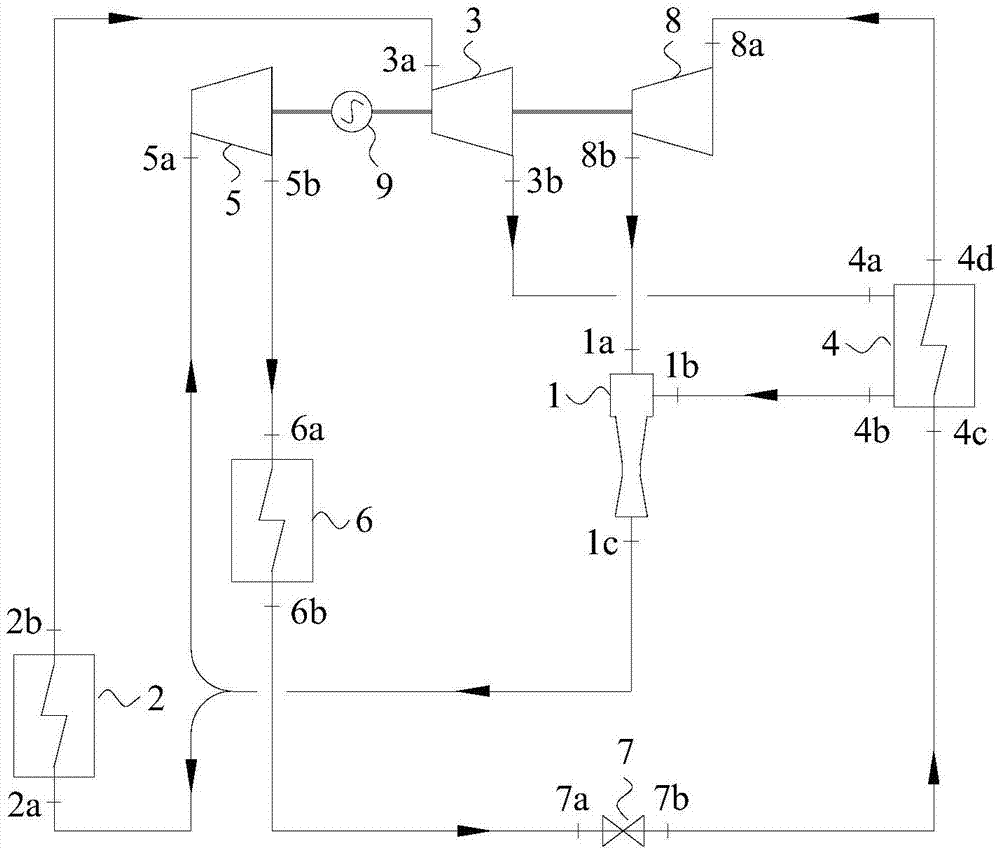

[0037] figure 1It is a schematic flow chart of an embodiment of the present invention. A pumpless organic Rankine cycle power generation system with compression refrigeration efficiency in this embodiment includes a supersonic vapor-liquid two-phase flow jet pump 1, an evaporator 2, an expansion machine 3, evaporative condenser 4, full-flow expander 5, cooler 6, throttle valve 7, compressor 8 and generator 9, wherein the expander 3 is a conventional expander, and the cooler 6 is a conventional condenser. The outlet 1c of the supersonic vapor-liquid two-phase flow jet pump 1 is divided into two paths, one path of refrigerant liquid is connected with the refrigerant liquid inlet 2a of the evaporator 2, and the refrigerant vapor outlet 2b of the evaporator 2 is connected with the vapor inlet of the expander 3 3a is connected, the exhaust gas outlet 3b of the expander 3 is connected with the refrigerant inlet 4a of the high temperature side of the evaporative condenser 4, and the ...

Embodiment 2

[0041] figure 2 It is a schematic flow chart of another embodiment of the present invention. This embodiment is a vortex tube type pumpless organic Rankine cycle power generation system with compression and refrigeration efficiency, including a supersonic vapor-liquid two-phase flow jet pump 1, evaporation 2, expander 3, evaporative condenser 4, vortex tube 10, cooler 6, throttle valve 7, compressor 8, and generator 9, wherein the expander 3 is a supplementary air expander, and the cooler 6 is liquid-cooled device. The outlet 1c of the supersonic vapor-liquid two-phase flow jet pump 1 is divided into two paths, one path of refrigerant liquid is connected with the refrigerant liquid inlet 2a of the evaporator 2, and the refrigerant vapor outlet 2b of the evaporator 2 is connected with the main vapor of the expander 3 The inlet 3a is connected; the other refrigerant liquid is connected with the inlet 10a of the vortex tube 10, the superheated steam outlet 10b of the vortex tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com