Production process of double-shaft orientated polyvinyl fluoride pipe material

A technology of biaxial orientation and polyvinyl fluoride, which is applied in the chemical industry, tubular articles, sustainable manufacturing/processing, etc., can solve the problems of not meeting production requirements and reducing the degree of orientation of pipes, so as to ensure product quality, save energy, The raw material is environmentally friendly and easy to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The composition of a biaxially oriented polyvinyl fluoride pipe is: 100 parts of PVC matrix resin, 3 parts of stabilizer, 2 parts of processing aid, 3 parts of toughening agent, 0.75 parts of lubricant, 2 parts of titanium dioxide, 0.04 parts of carbon black share.

Embodiment 2

[0020] The composition of a DN110 PN2.0 specification biaxially oriented polyvinyl chloride pipe is: 100 parts of PVC matrix resin (SG-5), 3.5 parts of stabilizer (stabilizer for calcium zinc and mercaptan methyl tin compound), processed Additive (ACR 301) 1.3 parts, toughening agent (ACR impact modifier) 3.5 parts, internal lubricant (solid lubricant of stearic acid complex alcohol ester) 0.45 parts, external lubricant (oxidized polyethylene wax) 0.35 parts, titanium dioxide (rutile titanium dioxide R-2196) 2.5 parts, carbon black 0.03 parts.

Embodiment 3

[0022] The composition of a DN225 PN1.6 biaxially oriented polyvinyl chloride pipe is: 100 parts of PVC matrix resin (SG-4), 3 parts of stabilizer (stabilizer for calcium zinc and mercaptan methyl tin composite), processing Auxiliary (ACR401) 2 parts, toughening agent (ACR impact modifier) 2.75 parts, internal lubricant (solid lubricant of stearic acid complex alcohol ester) 0.45 parts, external lubricant (oxidized polyethylene wax) 0.35 parts parts, titanium dioxide (rutile titanium dioxide R-2196) 1.7 parts, carbon black 0.035 parts.

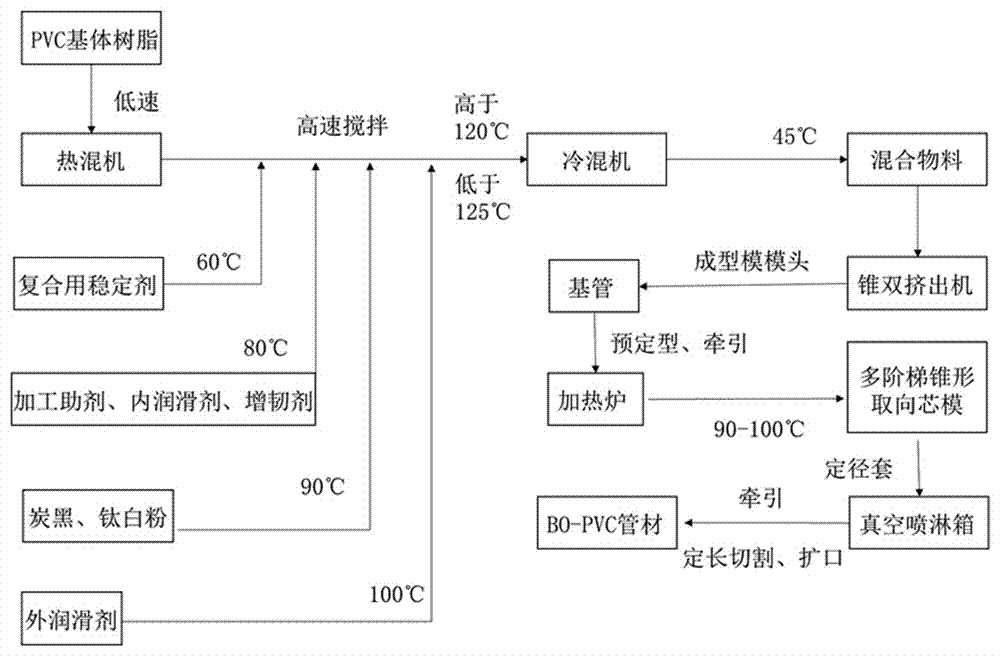

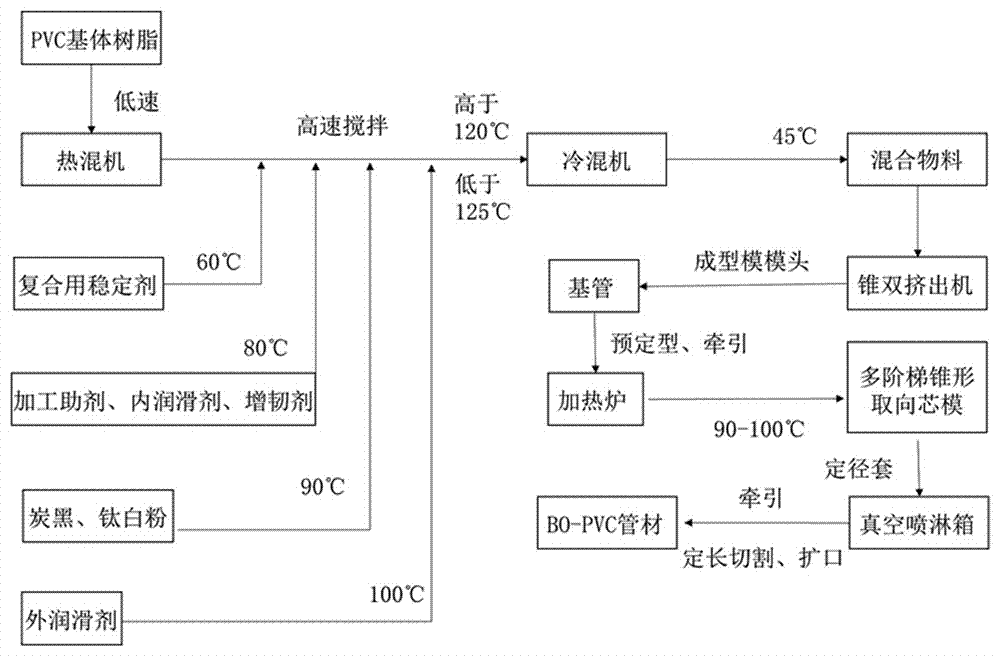

[0023] A biaxially oriented polyvinyl fluoride pipe is completed through the following preparation process steps: (1) Add the above-mentioned raw materials to a high-speed mixer in the proportion shown, and use the high-speed mixer blades to fully mix the raw materials to a uniform state, and ensure the temperature of the mixture When it reaches 120~125°C, put the mixture into the low-speed cold mixer again, and when the temperature of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com