Daily-chemical organic-silicon elastomer powder and preparation method and application thereof

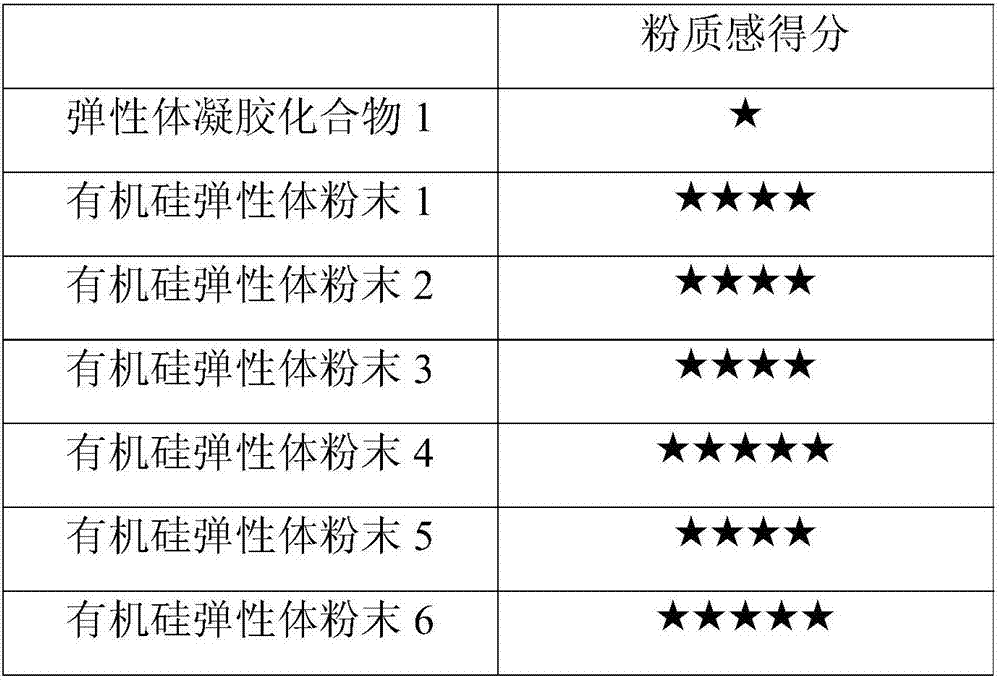

A technology of silicone and elastomer, which is applied in the field of silicone elastomer powder for daily use and its preparation, can solve the problem of greasy formula, achieve good performance, overcome the effect of strong greasy feeling, good smoothness and powdery texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

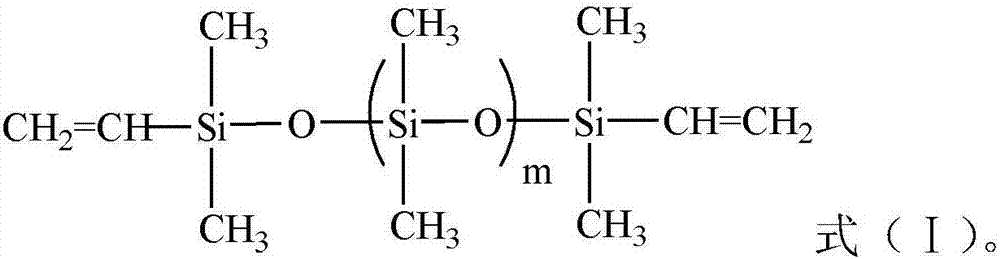

[0027] Into a 1000mL four-neck round bottom flask equipped with mechanical stirring and condensing and reflux devices, 20g of hydrogen-containing polysiloxane with a H content of 0.05wt.% and a viscosity of 100cSt, and 37.9g of α, ω-divinyl-terminated polysiloxane were successively added. Siloxane (m=100, M n =7586) (the molar ratio of C=C and Si-H bond is 1:1 in two kinds of materials), 3.0g polyoxyethylene-30 dipolyhydroxystearate (the amount of dispersing agent is 1wt.%) and 243.6g ethanol (the amount of solvent is 80wt.%), turn on the mechanical stirring and heat up to 70°C, add the calculated amount of vinyl platinum complex catalyst, so that the metal platinum concentration in the system is 3.0ppm, and react at this temperature for 5h After the reaction, cool down to room temperature, filter under reduced pressure using a Buchner funnel, collect the filter cake into an open beaker, and remove the residual solvent in a vacuum drying oven at 50°C with a vacuum degree >-0...

Embodiment 2

[0029] Into a 1000mL four-neck round bottom flask equipped with mechanical stirring and condensing and reflux devices, 40g of hydrogen-containing polysiloxane with a H content of 0.1wt.% and a viscosity of 100cSt, and 93.4g of α, ω-divinyl-terminated polysiloxane were successively added. Siloxane (m=50, M n =3886) (the molar ratio of C=C and Si-H bond is 1.2:1 in two kinds of materials), 2.7g polyoxyethylene-30 dipolyhydroxystearate (the amount of dispersing agent is 1wt.%) and 136.1g n-propanol (the amount of solvent is 50wt.%), open mechanical stirring and be warming up to 80 ℃, add the vinyl platinum complex catalyst of calculated amount, make the metal platinum concentration in the system be 4.0ppm, at this temperature React for 5 hours, cool to room temperature after the reaction, use a Buchner funnel to filter under reduced pressure, collect the filter cake into an open beaker, and remove the residual solvent in a vacuum oven at 50°C with a vacuum degree >-0.095MPa to ob...

Embodiment 3

[0031] In a 1000mL four-necked round-bottomed flask equipped with mechanical stirring and condensing reflux devices, 20g of hydrogen-containing polysiloxane with a H content of 0.2wt.% and a viscosity of 300cSt, 93.3g of α, ω-divinyl-terminated poly Siloxane (m=50, M n =3886) (the molar ratio of C=C and Si-H bond is 1.2:1 in two kinds of materials), 12.6g polyoxyethylene-30 dipolyhydroxystearate (the amount of dispersing agent is 2wt.%) and 478.4g isopropanol (the amount of solvent is 80wt.%), open mechanical stirring and be warmed up to 80 ℃, add the vinyl platinum complex catalyst of calculated amount, make the metal platinum concentration in the system be 2.0ppm, at this temperature React for 6 hours, cool to room temperature after the reaction, use a Buchner funnel to filter under reduced pressure, collect the filter cake into an open beaker, and remove the residual solvent in a vacuum oven at 50°C and vacuum >-0.095MPa to obtain a white powder, which is Silicone elastome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com