Preparing method and application of active carbon fiber loaded Ag/TiO2 compound catalytic material

A technology of activated carbon fibers and catalytic materials, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxides/metal hydroxide catalysts, etc. Low pore volume, low specific surface area, etc., to achieve the effect of eliminating shedding, facilitating industrialization, and simple operation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

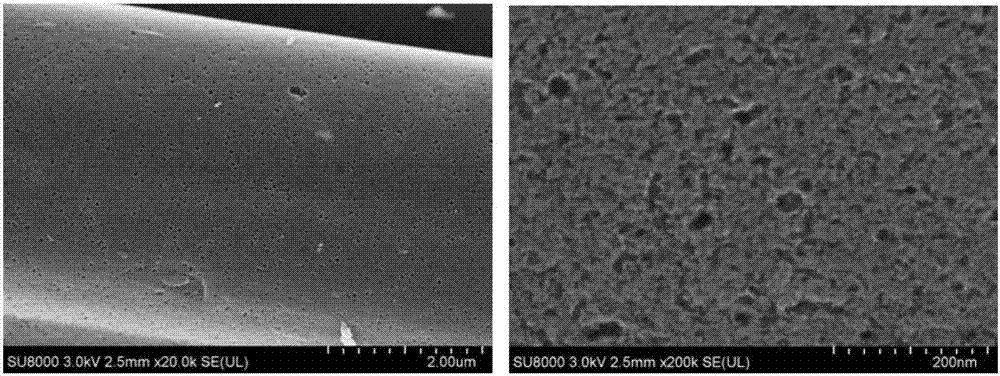

[0037] Example 1 preparation of activated carbon fiber loaded Ag / TiO 2 product one

[0038] (1) Pretreatment

[0039] Activated carbon fiber felt (ST1800 type activated carbon fiber felt produced by Jiangsu Sutong Carbon Fiber Co., Ltd., specific surface area 1775.04m 2 / g, the average pore diameter is 0.859nm) uniformly cut into 3×3cm 2 Each 10g of small cubes was packed into a 500mL round-bottomed flask, soaked in water for more than 5 minutes, and heated and cooled to reflux for 1 hour using a reflux condenser. Take out the activated carbon fiber felt and wash it with distilled water to neutral immediately, then dry it in an oven at 110°C and store it for later use.

[0040] (2) Preparation of Ag / TiO by sol-gel method 2 sol

[0041] 5 mL of tetrabutyl titanate was added into 35 mL of absolute ethanol with stirring, then 2 mL of glacial acetic acid was added to the above solution, and the mixed solution was stirred at room temperature for 2 h. Take 15mL absolute ethano...

Embodiment 2

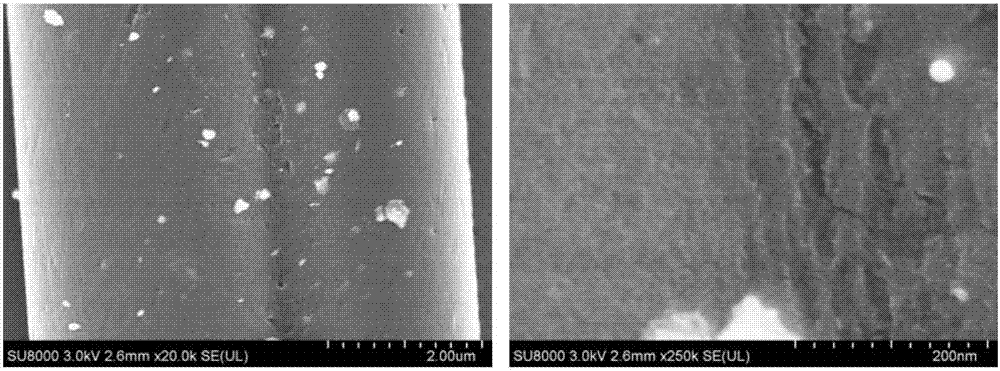

[0045] Example 2 preparation of activated carbon fiber loaded Ag / TiO 2 product two

[0046] The difference from Example 1 is that step (2) is: 5 mL of tetrabutyl titanate solution is added to 35 mL of absolute ethanol under stirring, then 2 mL of glacial acetic acid is added to the above solution, and the mixed solution is heated at room temperature Under stirring for 2h. Take 15mL absolute ethanol and add to 5mLAgNO 3 solution, and then add 1 mL of concentrated nitric acid, and add this mixed solution dropwise to the ethanol solution of tetrabutyl titanate above under stirring, and keep vigorously stirring for 2 hours. Other steps are identical with embodiment 1, obtain active carbon fiber loading Ag / TiO 2 product two. Product Field Emission Scanning Electron Microscope (FESEM) characterization picture image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com